Processing technology for flavored vegetarian meat

A processing technology and flavor technology, applied in the direction of vegetarian ingredients (no meat), vegetarian ingredients (no all animal products), food ingredients as taste modifiers, etc. The problem of high oil content in meat can ensure the taste, the market response effect is good, and the cost is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

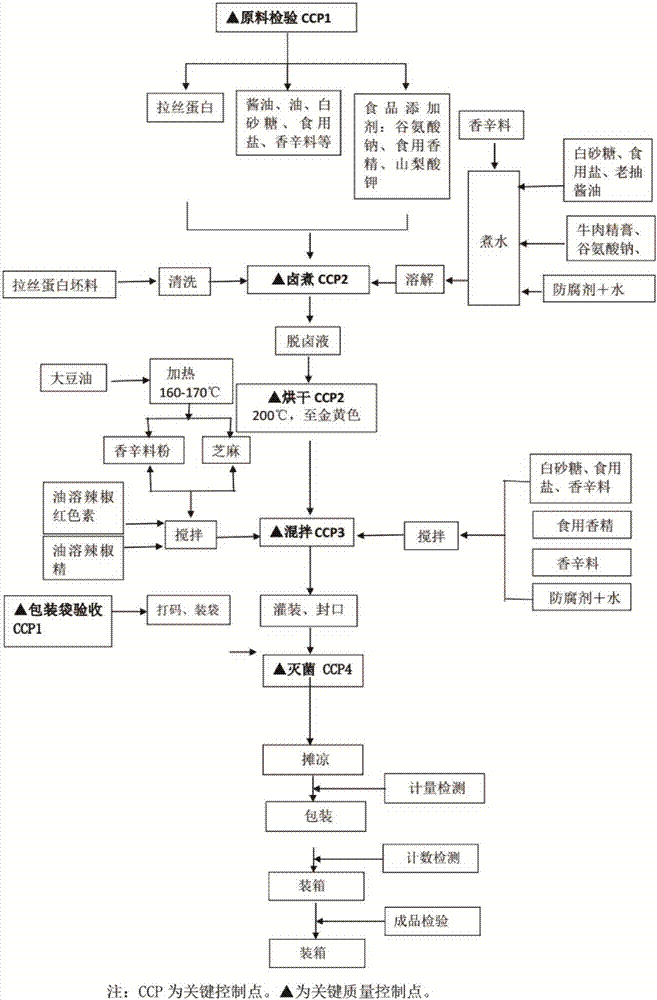

Image

Examples

Embodiment 1

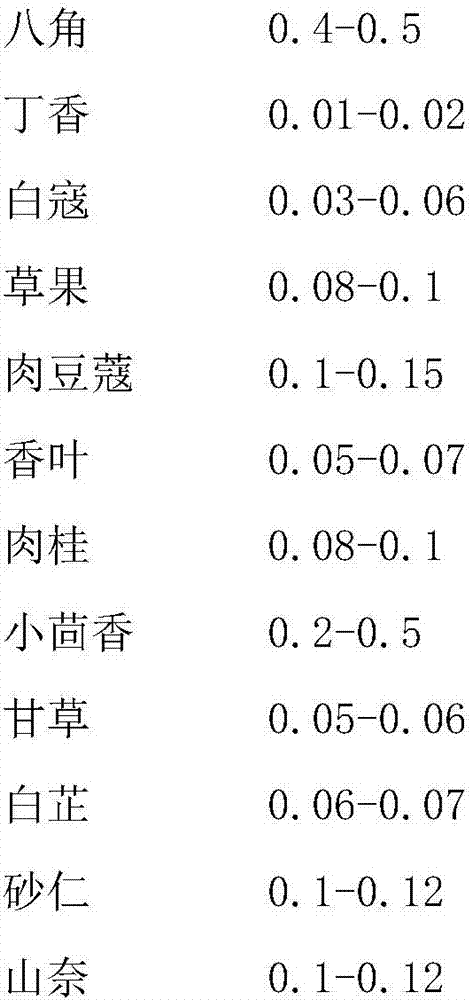

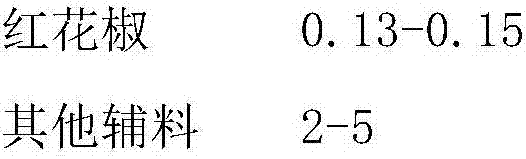

[0061] A kind of processing technology of spicy flavor vegetarian meat is characterized in that, comprises the following steps:

[0062] (1) Preparation work:

[0063] Raw material inspection before raw material cleaning

[0064] The drawn protein blanks should meet the requirements of the "Incoming Inspection Standards for Vegetarian Meat Raw Materials".

[0065] Other auxiliary materials should comply with the corresponding national standards.

[0066] All kinds of food additives should meet the corresponding implementation standards, and the added amount should meet the regulations of GB 2760.

[0067] Put the brushed protein blanks that meet the quality requirements into a clean container, pour in clean water and use a colander to stir gently for 1 minute. After the impurities and dust in the blanks float on the water surface, dump the water and discard it; repeat this process 2-3 times before use; When there are too many impurities in the billet, the number of cleaning...

Embodiment 2

[0089] A kind of processing technology of shallot and black pepper flavor vegetarian meat is different from embodiment 1 in that the formula of flavor seasoning is different; first, 5.78 kg of salt, 7.23 kg of sugar, and 7.23 kg of monosodium glutamate are added, and 5 kg of water is added to a clean stirring container to stir Evenly, after making an aqueous solution, add 67.47kg oil chili pepper, 1.45kg black pepper powder, 0.96kg black pepper powder, 0.48kg onion powder, 8.67kg beef essence, 0.24kg fried onion essence, and 0.24kg roast beef essence. After the granular material is obtained, the spicy flavor seasoning is obtained, and the spicy flavor seasoning is mixed with the above-mentioned drawing protein blank according to the ratio of 1:4.8 for 20 minutes until the finished product is stirred evenly;

[0090] Subsequent process is identical with embodiment 1.

[0091] In the above-mentioned embodiments of the present invention, through raw material processing and marina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com