Iron-loaded fly ash arsenic-removal adsorbent preparation method

A technology of fly ash and adsorbent, which is applied in the field of water treatment to achieve strong adsorption performance, strong renewability, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

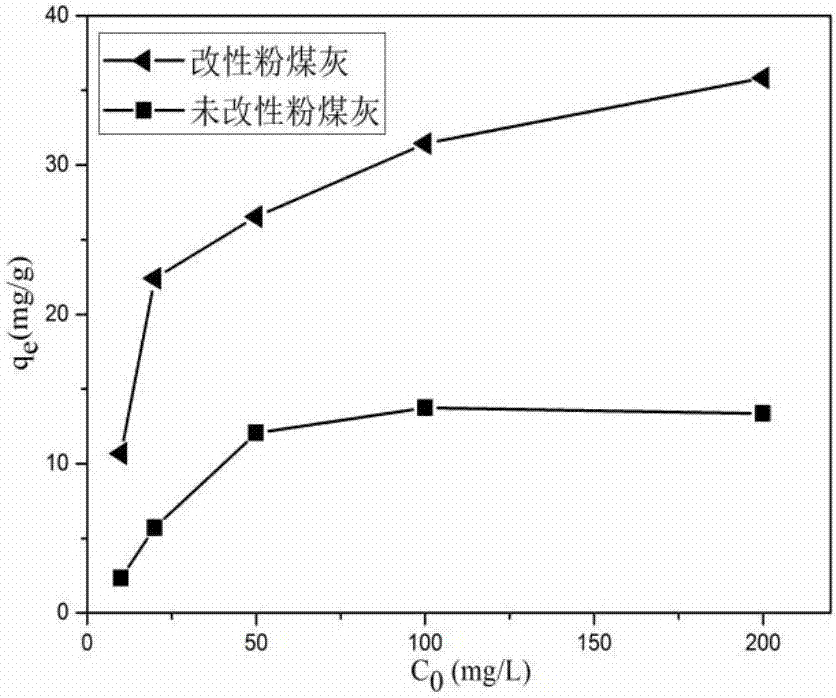

[0025] Build a test device, wash the fly ash with deionized water to remove impurities, pass through a 100-mesh sieve after drying, weigh 50 ml of fly ash, 250ml of NaOH solution with a concentration of 3mol / L, and stir in a constant temperature water bath at 40°C for 3 hours. Take it out and wash it with water until neutral; add 20ml of FeCl with a concentration of 0.1mol / L dropwise to the alkali-treated fly ash 3 The solution is stirred at 80°C until it becomes dry mud, so that the fly ash is buried in the modifier. The mixture is dried at a temperature of 80°C; after drying, it is passed through an 80-mesh sieve to obtain iron-loaded fly ash.

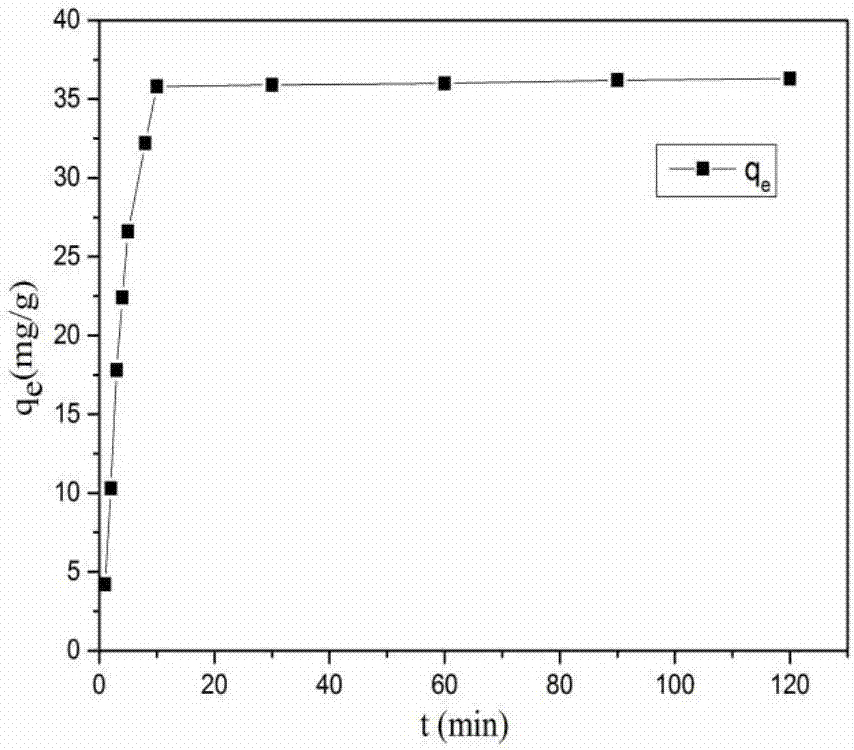

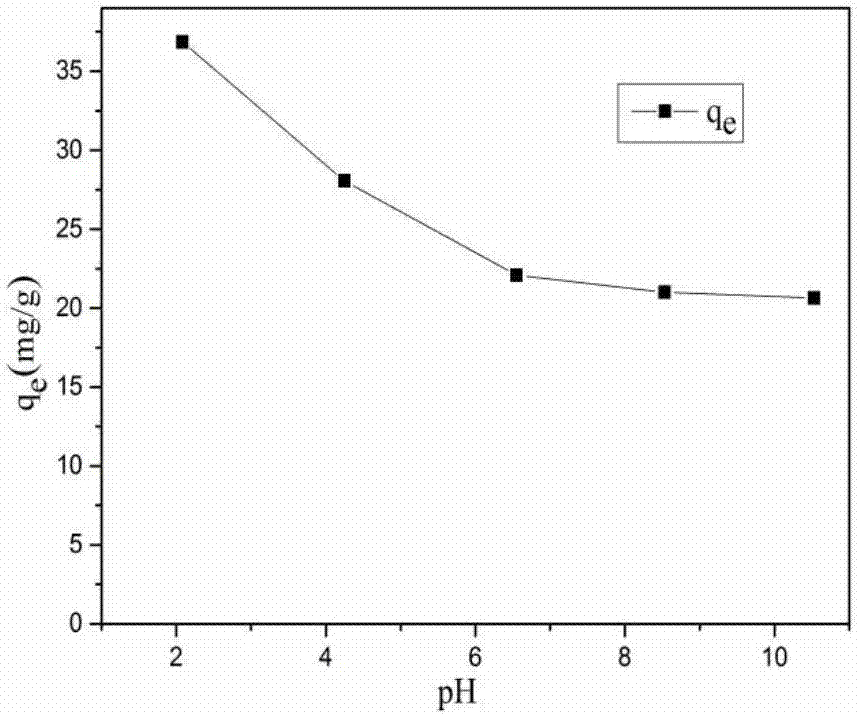

[0026] Na in the laboratory 3 AsO 4 Prepare arsenic-containing wastewater. For 20ppm arsenic-containing wastewater, the adsorbent dosage is 4g / L, oscillating for 2 hours, filtered with a needle tube with a filter head, diluted several times step by step, and obtained the adsorption equilibrium concentration with an atomic fluoresce...

Embodiment 2

[0028] Build a test device, wash the fly ash with deionized water to remove impurities, pass through a 120-mesh sieve after drying, weigh 45g of fly ash, 250ml of NaOH solution with a concentration of 4mol / L, and stir in a constant temperature water bath at 50°C for 3 hours. Take it out and wash it with water until neutral; add 20ml of FeCl with a concentration of 0.5mol / L dropwise to the alkali-treated fly ash 3 The solution is stirred at 80°C until it becomes dry mud, so that the fly ash is buried in the modifier; the mixture is dried at a temperature of 80°C; after drying, it is passed through a 100-mesh sieve to obtain iron-loaded fly ash;

[0029] Na in the laboratory 3 AsO 4 Prepare arsenic-containing wastewater. For 20ppm arsenic-containing wastewater, the adsorbent dosage is 4g / L, oscillating for 2 hours, filtered with a needle tube with a filter head, diluted several times step by step, and obtained the adsorption equilibrium concentration with an atomic fluorescence...

Embodiment 3

[0031] Build a test device, wash the fly ash with deionized water to remove impurities, pass through an 80-mesh sieve after drying, weigh 60g of fly ash, 250ml of NaOH solution with a concentration of 4mol / L, and stir in a constant temperature water bath at 60°C for 3 hours. Take it out and wash it with water until neutral; add 30ml of FeCl with a concentration of 1mol / L dropwise to the alkali-treated fly ash 3 The solution is stirred at 80°C until it becomes dry mud, so that the fly ash is buried in the modifier. The mixture is dried at a temperature of 80°C; after drying, it is passed through a 120-mesh sieve to obtain iron-loaded fly ash.

[0032] Na in the laboratory 3 AsO 4 Prepare arsenic-containing wastewater. For 20ppm arsenic-containing wastewater, the adsorbent dosage is 4g / L, oscillating for 2 hours, filtered with a needle tube with a filter head, diluted several times step by step, and then obtained the adsorption equilibrium concentration with an atomic fluoresc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com