Low-temperature low-turbidity period filter tank backwashing waste water coagulation reuse technical method

A technology for backwashing and waste water, which is applied in the direction of chemical instruments and methods, multi-stage water treatment, water/sewage treatment, etc., can solve the problem of not taking into account the enhanced coagulation of low-temperature and low-turbidity water, the limited effect of low-temperature and low-turbidity water enhancement, Problems such as low solid content of sediment at the bottom of the pond

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

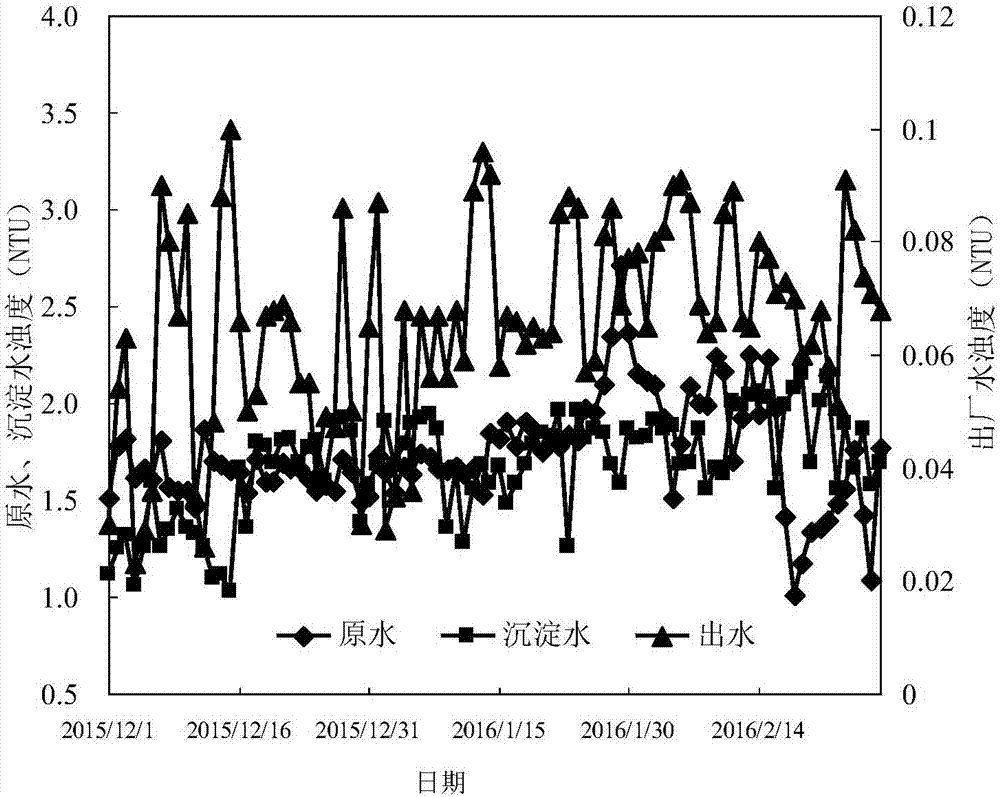

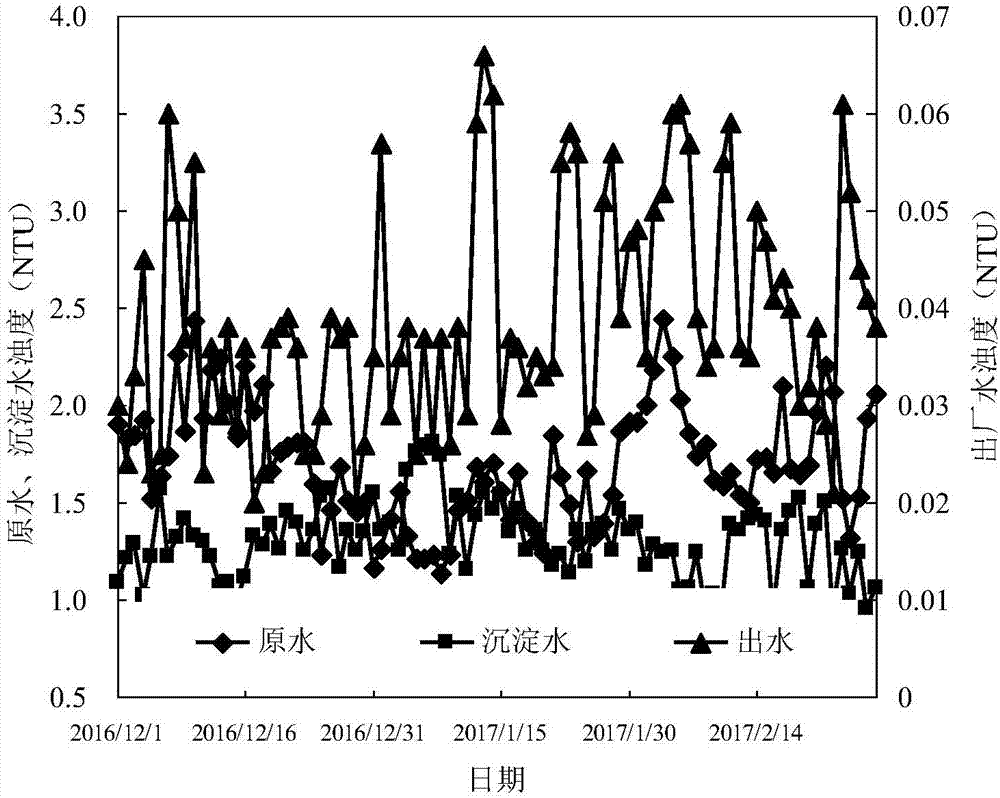

[0024] Attached below Figure 1-3 , through the description of the embodiment, the specific implementation of the present invention includes the shape, structure, mutual position and connection relationship of each part, the function and working principle of each part, the manufacturing process and the operation and use method of the various components involved. etc., to make further detailed descriptions to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

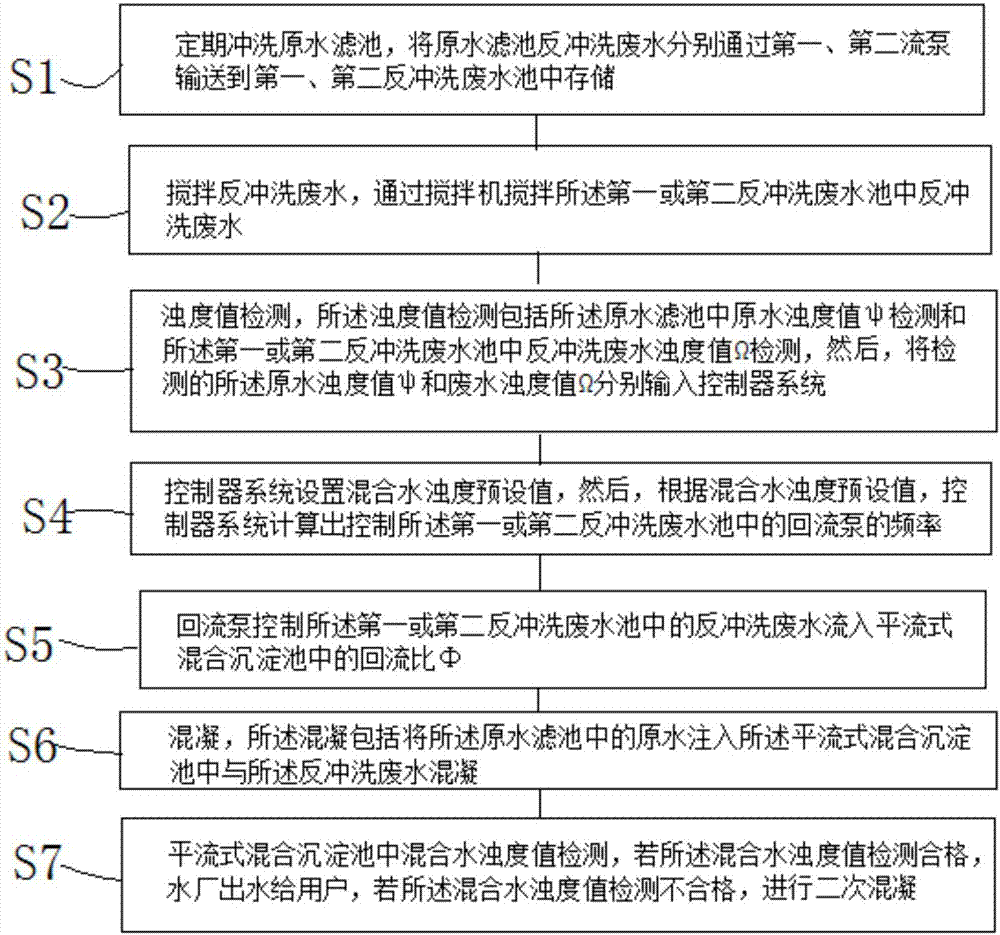

[0025] The low-temperature and low-turbidity stage filter backwash wastewater coagulation recycling technology method of the present invention comprises the following steps:

[0026] S1. Regularly flush the raw water filter, and transport the backwash waste water from the raw water filter to the first and second backwash waste water pools for storage through the first and second flow pumps respectively;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com