A method for preparing wollastonite glass-ceramics

A technology for glass-ceramic and wollastonite, which is applied in the field of preparing wollastonite glass-ceramic, can solve the problems of different crystallization conditions on the surface and inside, no coarse crystal flowers, shallow densification depth of the surface layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

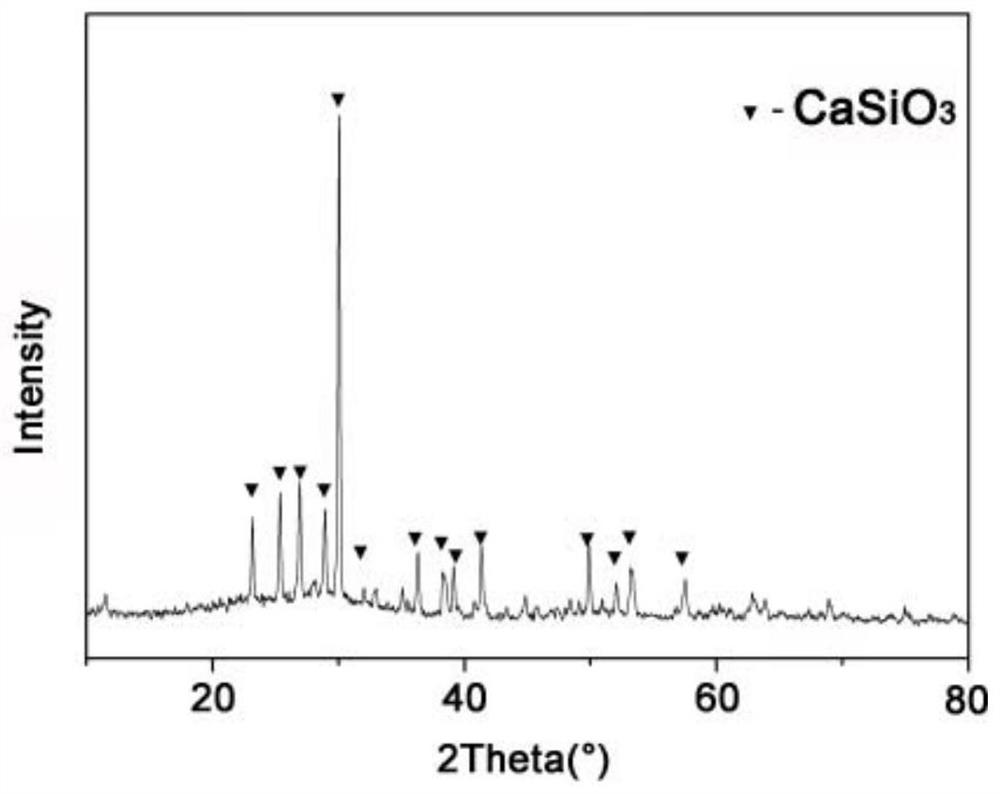

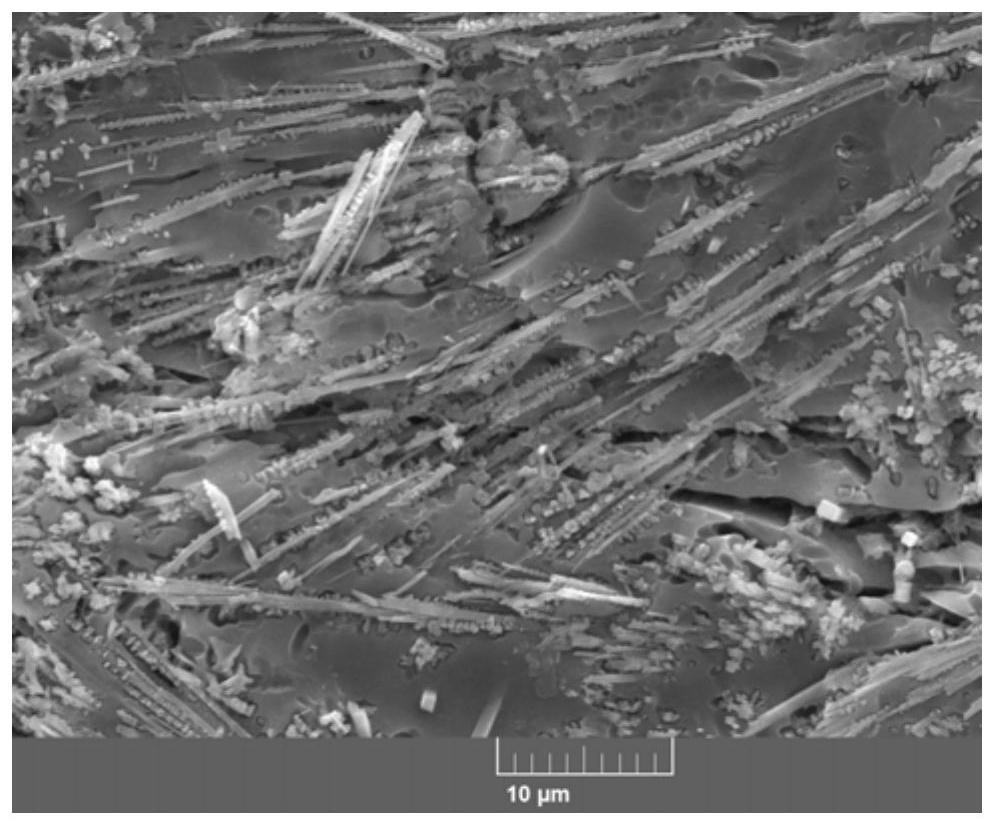

[0022] The present invention uses a high-voltage electric field to induce crystallization to prepare wollastonite glass-ceramics. The method includes two processes: melting of matrix glass, crystallization and sintering of glass-ceramics, and is specifically carried out according to the following steps:

[0023] 1) Mixing of raw materials: CaCO 3 , SiO 2 、Na 2 O.B 2 o 3 , ZnO, Al 2 o 3 , MgO, K 2 O.P 2 o 5 Mix well to obtain a mixture. The specific ratio of raw materials is shown in Table 1 below.

[0024] The weight percentage of each raw material of table 1 embodiment 1

[0025] CaCO 3

SiO 2

Na 2 o

B 2 o 3

ZnO al 2 o 3

MgO K 2 o

P 2 o 5

total wt.% 26 54 4 2.5 3 3.5 2 2 3 100

[0026] 2) Use absolute ethanol to prepare the mixture into a slurry, the mass ratio of absolute ethanol to the mixture is 2.6:1; the slurry is ball milled for 4 hours and then put into a drying box, and the dr...

Embodiment 2

[0034] 1) Mixing of raw materials: CaCO 3 , SiO 2 、Na 2 O.B 2 o 3 , ZnO, Al 2 o 3 , MgO, K 2 O.P 2 o 5 (One or more of lanthanum oxide, cerium oxide, neodymium oxide, erbium oxide or terbium oxide) are mixed evenly to obtain a mixture. The specific raw material ratios are shown in Table 3 below.

[0035] The weight percent of each raw material of table 3 embodiment 2

[0036] CaCO 3

SiO 2

Na 2 o

B 2 o 3

ZnO al 2 o 3

MgO K 2 o

P 2 o 5

total wt.% 38 49 3 1.5 2 1.5 1.5 1.5 2 100

[0037] 2) Use absolute ethanol to prepare the mixture into a slurry, the mass ratio of absolute ethanol to the mixture is 2.8:1; the slurry is ball milled for 4 hours and then put into a drying box, and the drying temperature is 40°C. Dry it, then keep it at 850°C for 3 hours to get a calcined block, put the calcined block into a high-purity corundum crucible, keep it in a muffle furnace at 1480°C for 4 hours t...

Embodiment 3

[0043] 1) Mixing of raw materials: CaCO 3 , SiO 2 、Na 2 O.B 2 o 3 , ZnO, Al 2 o 3 , MgO, K 2 O.P 2 o 5 (One or more of lanthanum oxide, cerium oxide, neodymium oxide, erbium oxide or terbium oxide) are mixed evenly to obtain a mixture. The specific ratio of raw materials is shown in Table 5 below.

[0044] The weight percent of each raw material of table 5 embodiment 3

[0045] CaCO 3

SiO 2

Na 2 o

B 2 o 3

ZnO al 2 o 3

MgO K 2 o

P 2 o 5

total wt.% 34 51 3 2 2 1.5 1.5 1.5 2.5 100

[0046] 2) Use absolute ethanol to prepare the mixture into a slurry, the mass ratio of absolute ethanol to the mixture is 2.55:1; the slurry is ball milled for 4 hours and then put into a drying box, and the drying temperature is 40°C. Dry it, then keep it at 850°C for 4.5h to get a calcined block, put the calcined block into a high-purity corundum crucible, and keep it at 1480°C for 3.5h in a muffle furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com