Method for producing rosin ester and rosin ester

A manufacturing method and technology of rosin ester, which is applied in the field of rosin ester manufacturing, can solve problems such as the easy deterioration of color tone, and achieve the effect of excellent heating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

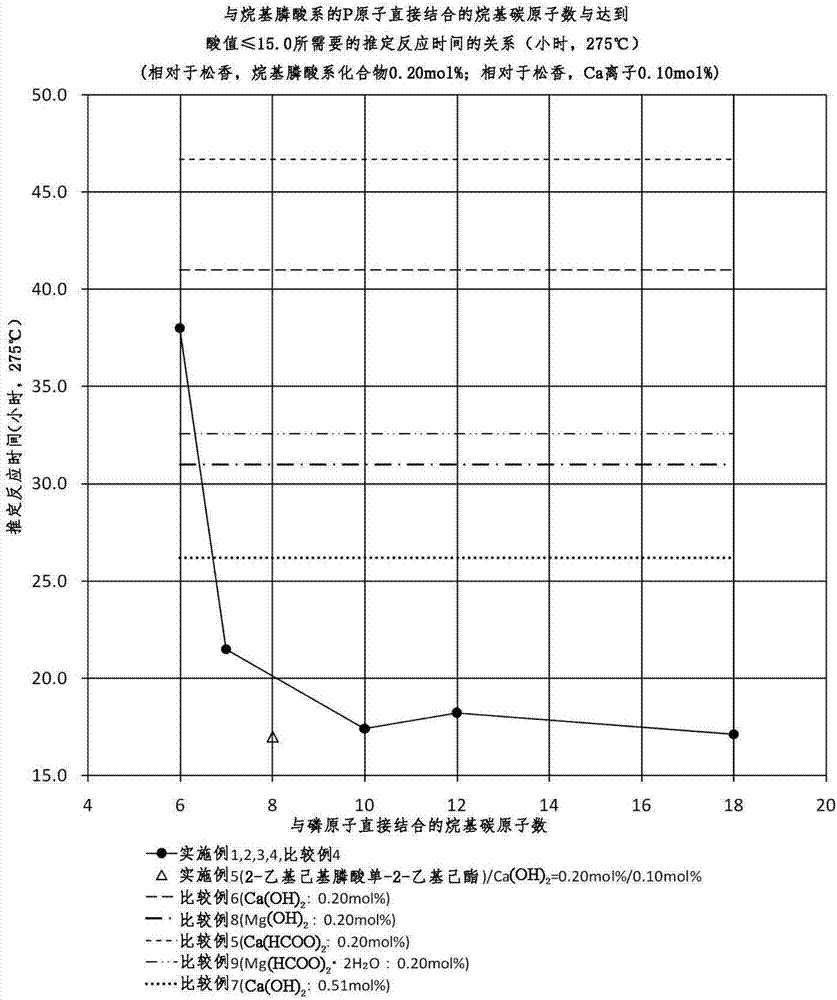

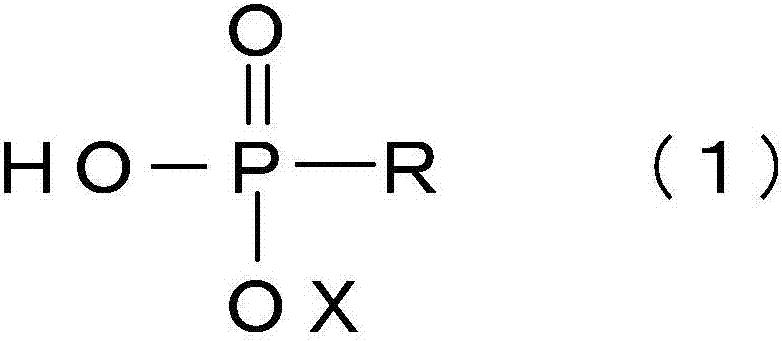

[0073] In a four-necked eggplant-shaped flask with a capacity of 500 ml equipped with a water separator connected to a spherical condenser at the upper end, a stirrer, and a nitrogen introduction pipe, add Chinese gum rosin (WW grade: acid value 170.0, softening point 86.0 ° C, color tone 8+G, the following, same as "Chinese gum rosin") 300 parts, heated under nitrogen stream to melt. Subsequently, when the reaction system reached 160°C, 0.34 parts of heptylphosphonic acid, 0.07 parts of calcium hydroxide and a sulfur-based disproportionation catalyst (4,4'-thiobis(6-tert-butyl-3-methyl 1.2 parts of phenol) (trade name Sumiraizer WX-R, manufactured by Sumitomo Chemical Co., Ltd.), and 29.4 parts of pentaerythritol were added when the reaction system reached 180°C. Thereafter, the reaction system was brought to 275° C. over about 2 hours, and this time point was defined as the 0th hour, and sampling was performed from the 2nd hour (6 times in total), and the acid value of each ...

Embodiment 2~5

[0093] Using the raw materials shown in Table 1, rosin ester was produced by the same method as in Example 1, and the same sampling as in Example 1 was performed to evaluate the physical properties.

Embodiment 6

[0095] In the same reaction vessel as in Example 1, 200.0 parts of toluene and 46.8 parts of 2-ethylhexylphosphonic acid mono-2-ethylhexyl were charged, and 5.76 parts of calcium hydroxide were added little by little while stirring. After heating up for 1 hour to reflux, cool to room temperature and filter through filter paper. Subsequently, acetone, a poor solvent, was added to the filtrate at room temperature, and the precipitate was collected by filtration to obtain a white product. Thereafter, the white product was recrystallized to obtain 2-ethylhexylphosphonic acid mono-2-ethylhexyl calcium salt.

[0096] Subsequently, 300 parts of gum rosin was added to the same reaction vessel as in Example 1, and heated under nitrogen flow to melt it. Subsequently, at the point when the reaction system reached 160°C, 0.60 parts of the esterification catalyst shown in Table 1 (the aforementioned 2-ethylhexylphosphonic acid mono-2-ethylhexyl calcium salt) and Sumilaizer WX-R 1.2 29.4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com