A kind of water-based composite solid wood multi-layer floor veneer bottom veneer glue and preparation method thereof

A water-based, solid wood technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of poor storage stability, shorten the life of wooden floors, and human health hazards, achieve strong water resistance, and improve bonding strength , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

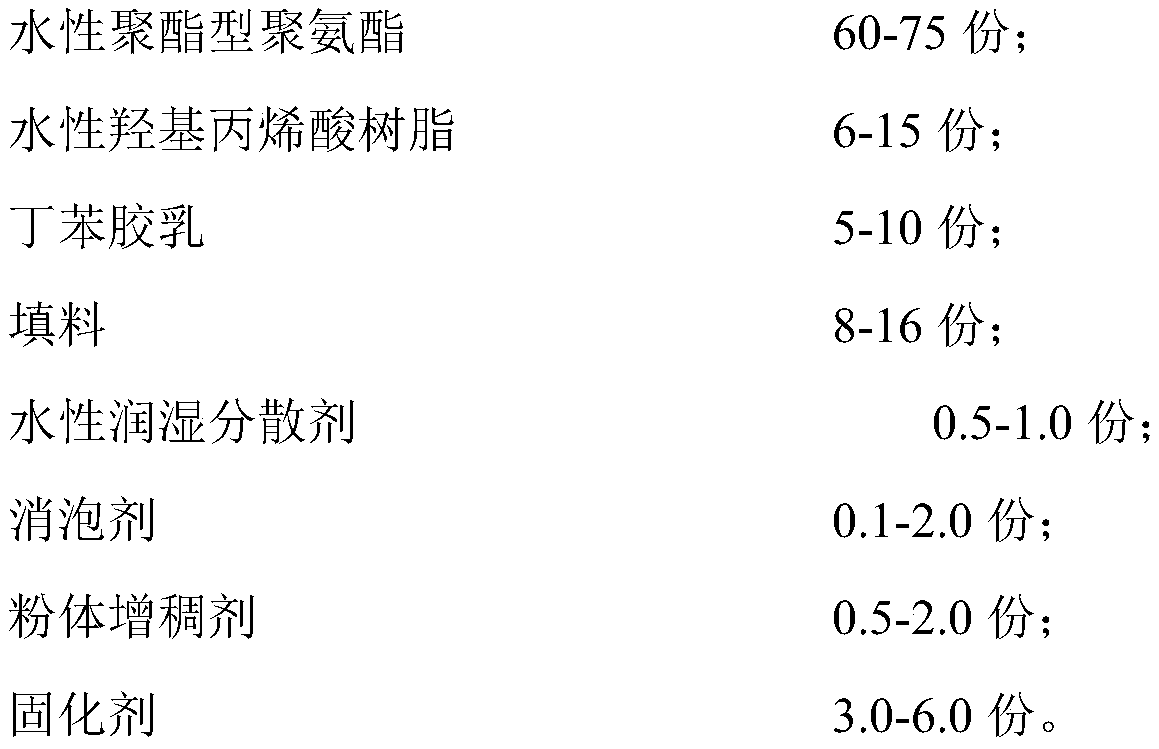

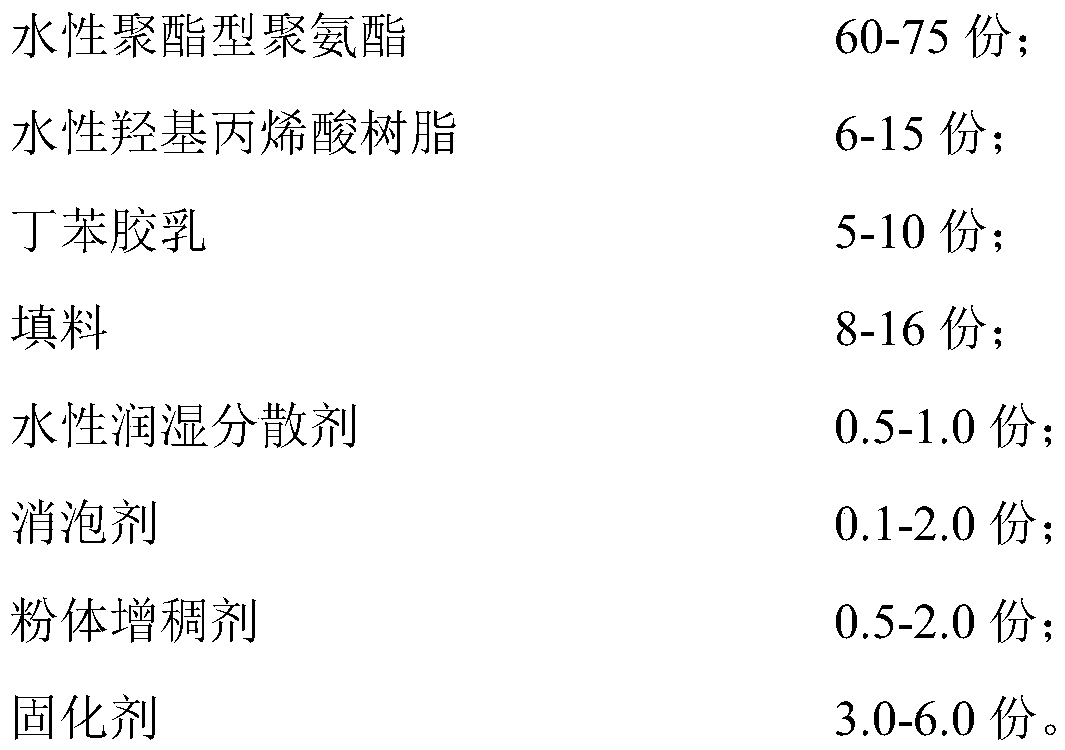

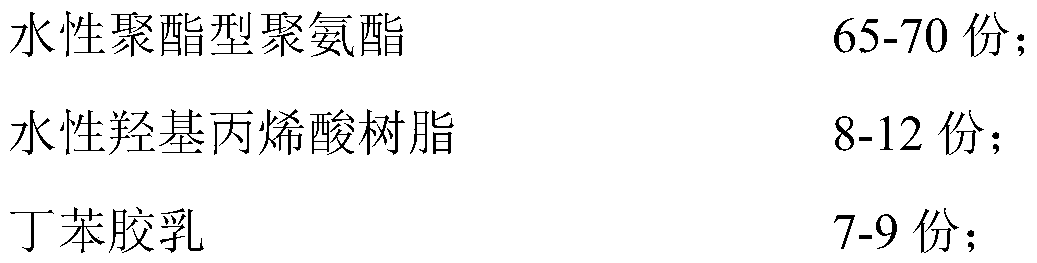

Method used

Image

Examples

Embodiment 1

[0037] 1) Put 60kg of water-based polyester polyurethane and 0.8kg of water-based wetting and dispersing agent (model ECODIS P50) in the stainless steel container of the high-speed disperser, turn on the disperser, control the speed at 300r / min, and after dispersing for 6 minutes, add 10kg Filler (calcite powder), increase the speed to 700r / min for high-speed dispersion, then add 0.3kg of defoamer (model YMT-322), after dispersing for 25min, add 15kg of water-based hydroxyacrylic resin (model YPWA-22W02), 7kg of styrene-butadiene latex (model TG201) and 0.8kg of powder thickener (model BENTONE DE) were uniformly dispersed to obtain a preliminary slurry, and the viscosity of the preliminary slurry was controlled to 40,000 mPa.s.

[0038] 2) Add 3.5kg of curing agent (amino resin crosslinking agent) to the prepared slurry before use, and disperse evenly to obtain water-based composite solid wood multi-layer floor glue.

Embodiment 2

[0040] 1) Put 65kg of water-based polyester polyurethane and 1.0kg of water-based wetting and dispersing agent (model BFK-1600W) in the stainless steel container of the high-speed disperser, turn on the disperser, control the speed at 300r / min, and after dispersing for 6 minutes, add For 12kg of filler (wood powder), increase the speed to 800r / min for high-speed dispersion, then add 0.3kg of defoamer (model Defom W-052), and after dispersing for 25min, add 12kg of water-based hydroxyacrylic resin (model YPWA-22W02 ), 8kg of styrene-butadiene latex (model SD417) and 1.0kg of powder thickener (model BENTONE DE), uniformly dispersed to obtain a preliminary slurry, the viscosity of the preliminary slurry is controlled to 42,000 mPa.s.

[0041] 2) Add 4.0kg of curing agent (amino resin crosslinking agent) to the prepared slurry before use, and disperse evenly to obtain water-based composite solid wood multi-layer floor glue.

Embodiment 3

[0043] 1) Put 68kg of water-based polyester polyurethane and 0.7kg of water-based wetting and dispersing agent (model ECODIS P50) in the stainless steel container of the high-speed disperser, turn on the disperser, control the speed at 300r / min, and after dispersing for 6 minutes, add 14kg Filler (calcite powder), increase the speed to 700r / min for high-speed dispersion, then add 0.5kg of defoamer (model YMT-322), after dispersing for 25min, add 10kg of water-based hydroxyacrylic resin (model 8300), 9kg of Styrene-butadiene latex (model SD417) and 1.0kg of powder thickener (model BENTONE DE) are uniformly dispersed to obtain a preparatory slurry, and the viscosity of the preparatory slurry is controlled to 40,000 mPa.s.

[0044] 2) Add 4.5kg of curing agent (polycarbodiimide) to the prepared slurry before use, and disperse evenly to obtain water-based composite solid wood multi-layer floor veneer glue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com