Method for promoting accumulation of oil in microalgae and keeping high biomass of microalgae

A technology of microalgae oil and high biomass, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of adding plant hormones, etc., achieve simple operation, good applicability, and increase the biomass of microalgae effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

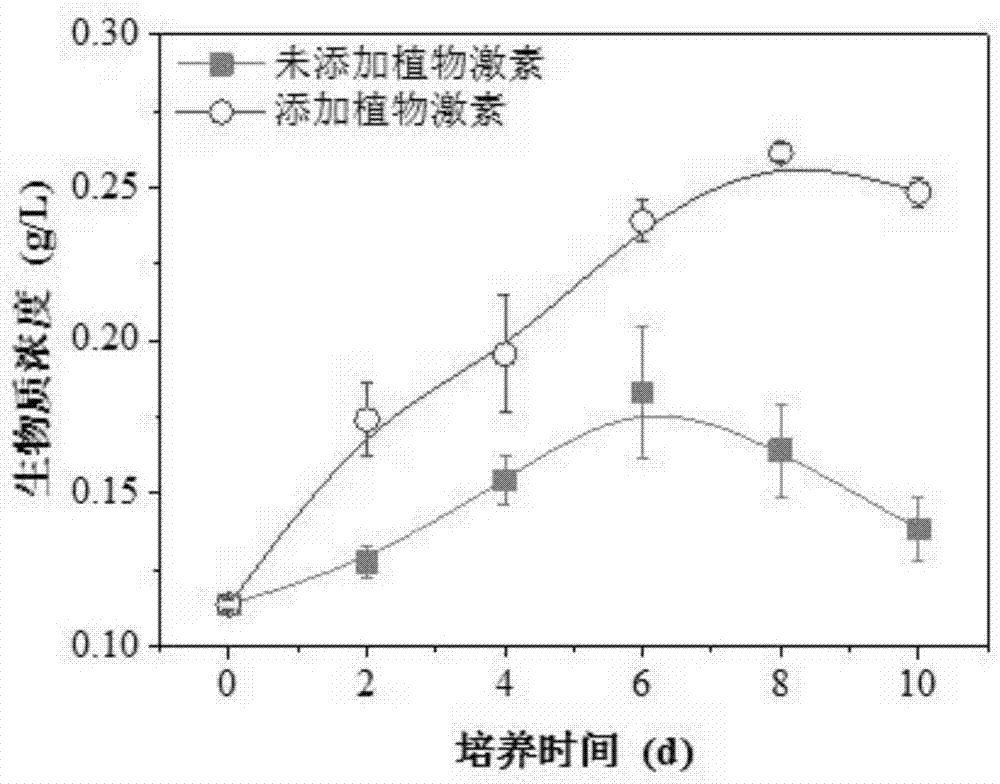

[0052] Example 1: Growth characteristics of Chlorella SDEC-6

[0053] 1. Algae culture process:

[0054] (1) Put Chlorella SDEC-6 in BG11 medium for enrichment culture, the composition of BG11 medium is as follows: NaNO 3 1.5g / L, K 2 HPO 4 40mg / L, MgSO 4 ·7H 2 O 75mg / L, CaCl 2 2H 2 O 36mg / L, citric acid 6 mg / L, ferric ammonium citrate 6mg / L, EDTANa 2 1mg / L,Na 2 CO 320mg / L, A5 solution 1mL / L; A5 solution is: H 3 BO 3 2.86g / L, MnCl 2 4H 2 O 1.86g / L, ZnSO 4 ·7H 2 O 0.22g / L,Na 2 MoO 4 2H 2 O 0.39 g / L, CuSO 4 ·5H 2 O0.08g / L, Co(NO 3 ) 2 ·6H 2 O 0.05g / L.

[0055] (2) The algal seed liquid obtained in step (1) is centrifuged, washed three times with nitrogen-deficient medium, and then reinoculated in nitrogen-deficient medium as a control group, with an initial dry weight of 0.11g / L.

[0056] (3) After centrifuging the algae seed liquid obtained in step (1), washing the nitrogen-deficient medium three times, re-inoculating in the nitrogen-deficient BG11 medium...

Embodiment 2

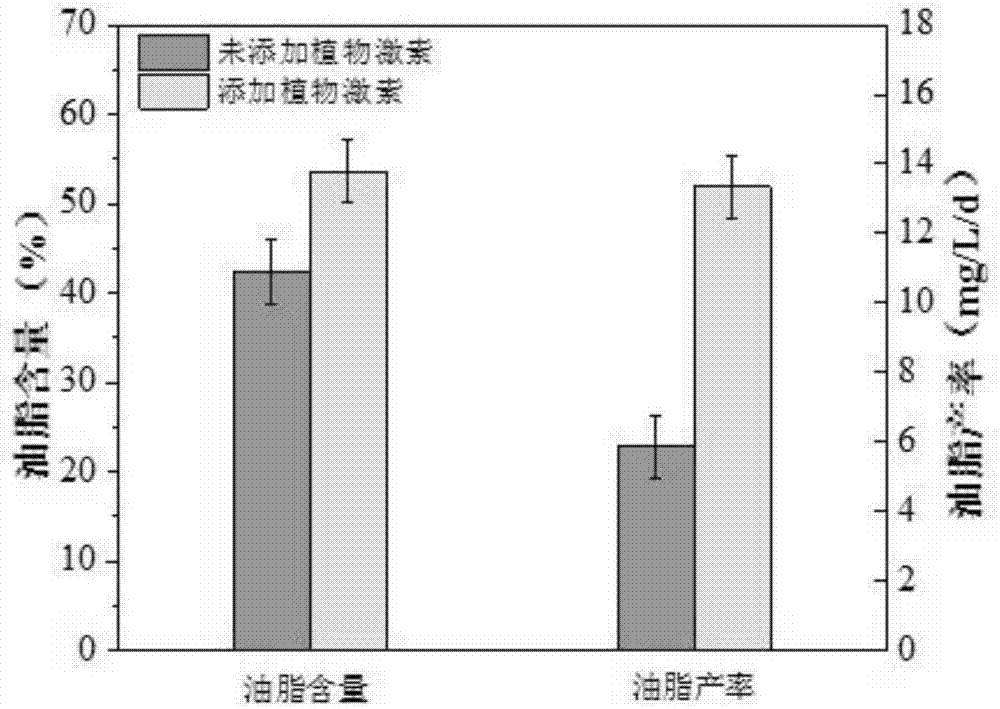

[0064] Example 2: Oil Accumulation Properties of Chlorella SDEC-6

[0065] 1. Determination of oil content:

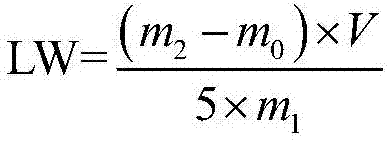

[0066] Weigh about 0.1 g of the dried algae powder obtained in Example 1 into a 50 mL centrifuge tube, add 10 mL of chloroform / methanol (v / v=2:1) solution, and process it with an ultrasonic breaker for 10 min (frequency 20%), then 4000 r After centrifugation, the solution was separated into two phases, and the supernatant was transferred to a 60mL separatory funnel, and the whole extraction process was repeated twice. According to the volume of the oil extract, add 0.9% sodium chloride solution (adding volume is 1 / 5 of the oil extract, about 4-5mL sodium chloride solution), shake well for 1 min, and let stand for 15 min. Measure the volume of the low-phase solution, and take 5mL of the low-phase solution in a 10mL glass test tube, blow dry with nitrogen, and place the glass tube in a 60°C oven to dry to constant weight (about 30min).

[0067] 2. Calculation of fat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com