Four-point bending beam-based bituminous mixture interlaminar shear strength testing device

A technology of interlayer shear strength and asphalt mixture, which is applied in the direction of applying stable shear force to test material strength, measurement devices, strength characteristics, etc., can solve the problem of inability to simulate the change of compressive stress and shear stress with the depth of the road surface, and the difficulty Reasonably explain and analyze problems such as the bonding between asphalt pavement layers to achieve the effects of reducing deformation, reducing impact, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

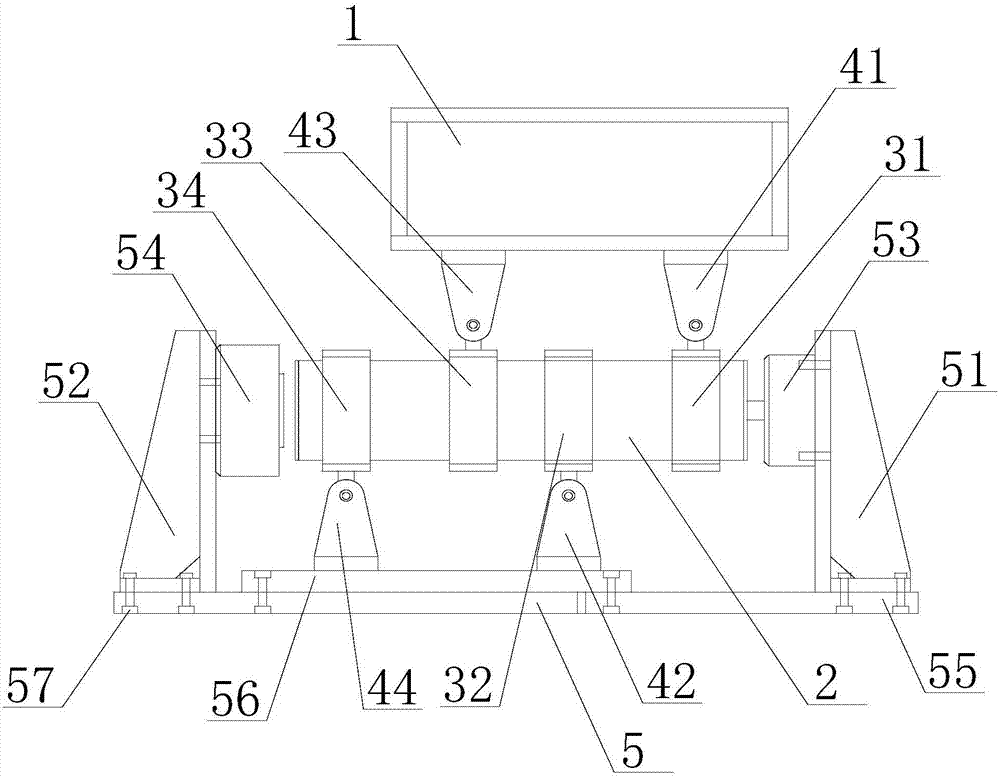

[0048] Such as figure 1 As shown, the present invention is based on the asphalt mixture interlayer shear strength testing device of the four-point bending beam method, including a loading I-beam 1, a bending beam clamp 3, a support 4 and a base 5; the loading I-beam 1, The test piece 2 and the base 5 are sequentially arranged from top to bottom; the bending beam fixture 3 includes a first bending beam fixture 31, a second bending beam fixture 32, a third bending beam fixture 33 and a fourth bending beam fixture 34; The support 4 includes a first support 41, a second support 42, a third support 43 and a fourth support 44; the first bending beam clamp 31, the second bending beam clamp 32, the third bending beam clamp 33 and the fourth bending beam fixture 34 are sequentially set on the test piece 2 along the axis of the test piece 2; the first support 41 and the third support 43 are installed on the bottom of the loading I-beam 1, and the first support 41 is hinged on the The f...

Embodiment 2

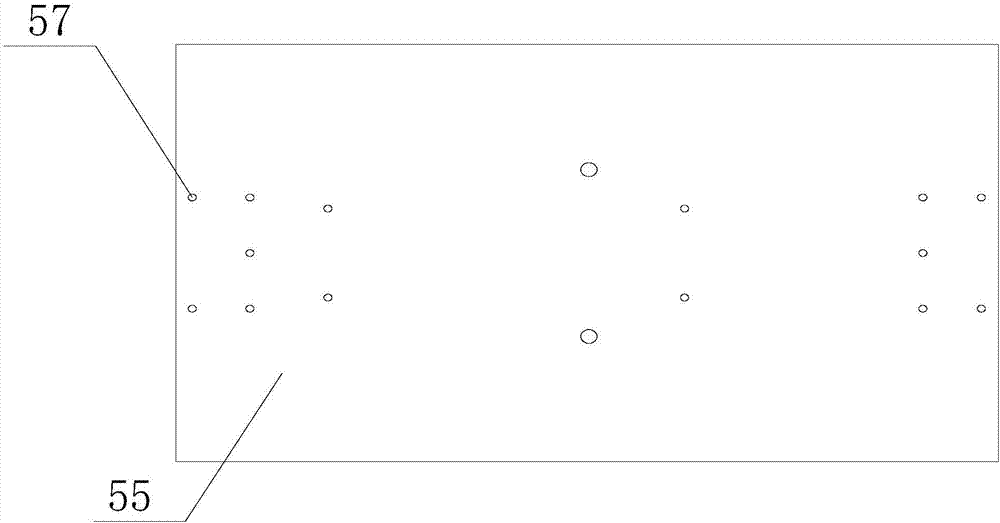

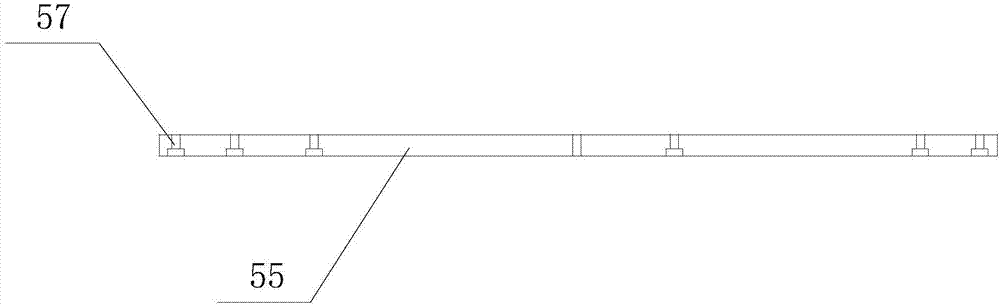

[0051] Such as Figure 14 , Figure 15 and Figure 16 As shown, in this embodiment, on the basis of embodiment 1, the size of the tested piece 2 is 50*70*280mm, Figure 15 and Figure 16 On the surface, there is no bending moment at the interlayer section of the specimen, and the shear force on the interlayer section is 11 / 15V, which is in line with the theoretical analysis results of material mechanics.

Embodiment 3

[0053] Such as figure 1 As shown, on the basis of Embodiment 1, this embodiment also includes a first baffle 51 and a second baffle 52 arranged on the top surface of the base 5; the first baffle 51 and the second baffle 52 face each other set, and the test piece 2 is located between the first baffle plate 51 and the second baffle plate 52; the first baffle plate 51 is provided with a tension and pressure sensor 53 on the surface facing the test piece 2; the second baffle plate 52 faces the test piece A horizontal jack 54 is arranged on the surface of the part 2 .

[0054] When this embodiment is implemented, the test piece 2 is loaded through the second baffle 51, and the force is monitored by the tension and compression sensor 53 on the first baffle 51. Since the first bending beam clamp 31 and the second bending beam The fixture 32, the third bending beam fixture 33 and the fourth bending beam fixture 34 are respectively hinged to the first support 41, the second support 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com