Composite foaming agent particles and preparation method thereof, and preparation method of aluminum foam

A technology of composite foaming agent and composite particles, which is applied in metal processing equipment, transportation and packaging, coating, etc., to achieve good reproducibility, reduce the requirements of melting temperature matching, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

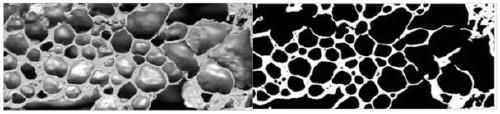

Image

Examples

preparation example Construction

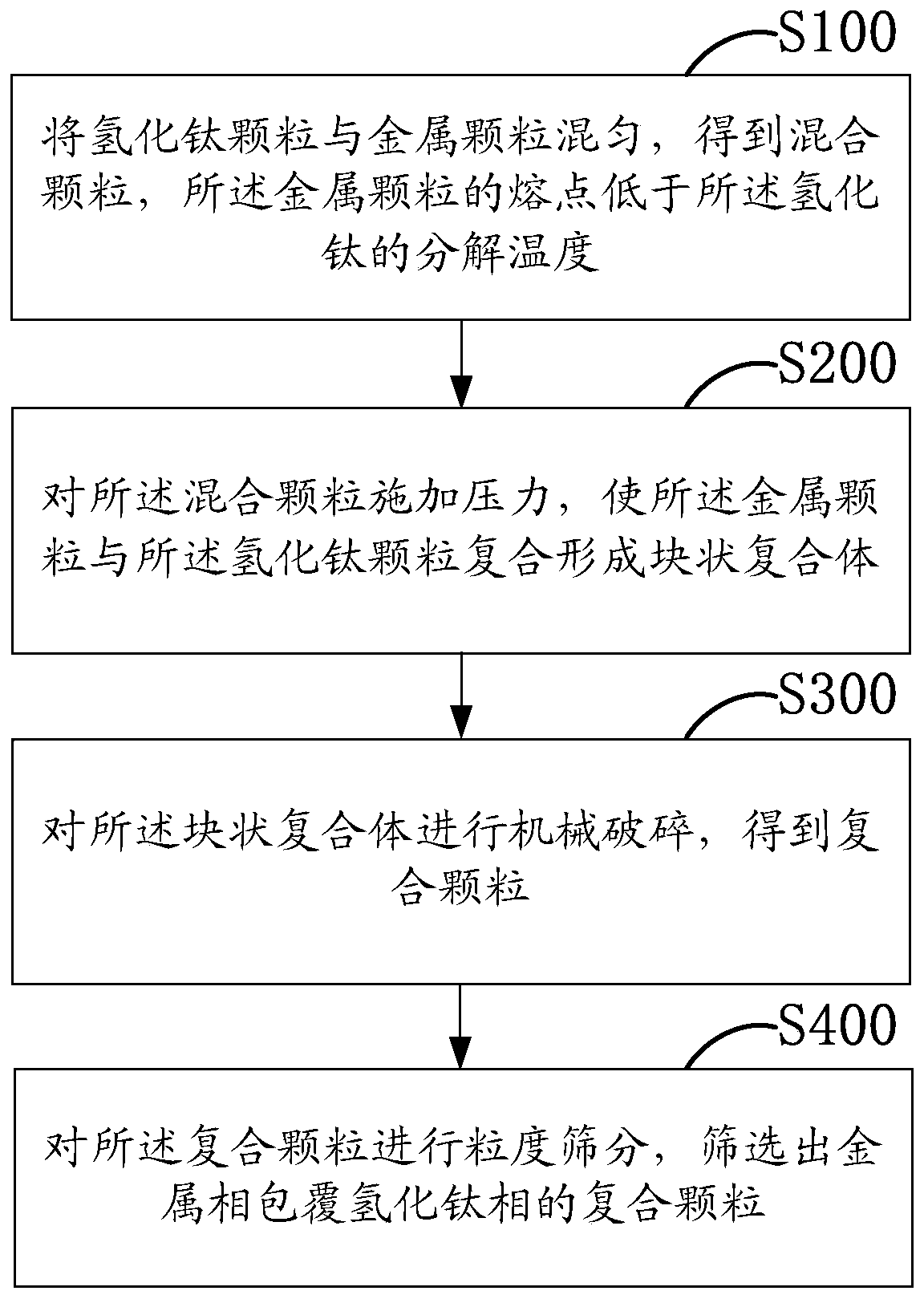

[0036] see figure 1 , the invention provides a kind of preparation method of composite blowing agent particle, comprising:

[0037] S100, uniformly mixing titanium hydride particles and metal particles to obtain mixed particles, the melting point of the metal particles is lower than the decomposition temperature of titanium hydride;

[0038] S200, applying pressure to the mixed particles, so that the metal particles and titanium hydride particles are combined to form a block composite;

[0039] S300, performing mechanical crushing on the bulk composite to obtain composite particles; and

[0040] S400, performing particle size screening on the composite particles, and screening the composite particles in which the metal phase coats the titanium hydride phase.

[0041] Using physical coating technology to mix, briquetting, crushing and screening titanium hydride particles and metal particles to obtain composite foaming agent particles with low melting point metal phase coating...

Embodiment 1

[0059] The preparation of embodiment 1 composite blowing agent particle

[0060] S100, uniformly mixing titanium hydride particles and metal particles. Among them, the metal particles are tin powder with a particle size of 500 mesh. The particle size of the titanium hydride particles was 300 mesh. The mass ratio of titanium hydride particles to tin powder is 1:8. The mixing operation was carried out on a three-dimensional mixer for 2 hours, and the frequency of the mixer was set at 40 Hz.

[0061] S200, after mixing, weigh 15g of the mixture and pour it into a cylindrical mold with an inner cavity of 30mm for uniaxial briquetting. After keeping it at 450MPa for 5min, a round block with a thickness of 3mm and a diameter of 30mm is obtained.

[0062] S300: For the pressed round sample, it is mechanically crushed by breaking, crushing, etc. to obtain composite particles.

[0063] S400, screen the particles after primary crushing, and screen out particles with a particle size ...

Embodiment 2

[0064] The preparation of embodiment 2 aluminum foam

[0065] The composite blowing agent particle that adopts embodiment 1 preparation prepares aluminum foam, after obtaining composite blowing agent particle, carry out following operations:

[0066] S500, mixing the aluminum powder with the obtained composite foaming agent particles, and pressing to obtain a foaming precursor.

[0067] S600, heating the foaming precursor to make the composite foaming agent particles foam. As the heating temperature increases, the precursor melts gradually, and finally an aluminum melt with a cellular structure is obtained.

[0068] S700, cooling the aluminum melt to obtain foamed aluminum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com