A kind of al-ti-c-nd master alloy and its preparation method and application

An al-ti-c-nd, master alloy technology, applied in the field of Al-Ti-C-Nd master alloy and its preparation, can solve the problems of poor TiC particle forming effect, large dosage, poor wettability, etc. The effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides a method for preparing the Al-Ti-C-Nd master alloy described in the above technical solution, comprising the following steps:

[0039] Aluminum powder, titanium powder, carbon powder and Nd 2 o 3 The powder is mixed and pressed into a mixed powder block;

[0040] Heat metal aluminum until it is completely melted to obtain aluminum melt;

[0041] Pressing the mixed powder block into the aluminum melt for thermal explosion reaction and then pouring to obtain Al-Ti-C-Nd master alloy.

[0042] The present invention will aluminum powder, titanium powder, carbon powder and Nd 2 o 3 The powders are mixed and pressed into a mixed powder block. In the present invention, the molar ratio of the aluminum powder, titanium powder and carbon powder is preferably 5:(1.5-2.5):(0.8-1.2), more preferably 5:(1.8-2.2):(0.9-1.1) ; The Nd 2 o 3 The mass of powder is preferably 2-6% of the total mass of aluminum powder, titanium powder and carbon powde...

Embodiment 1

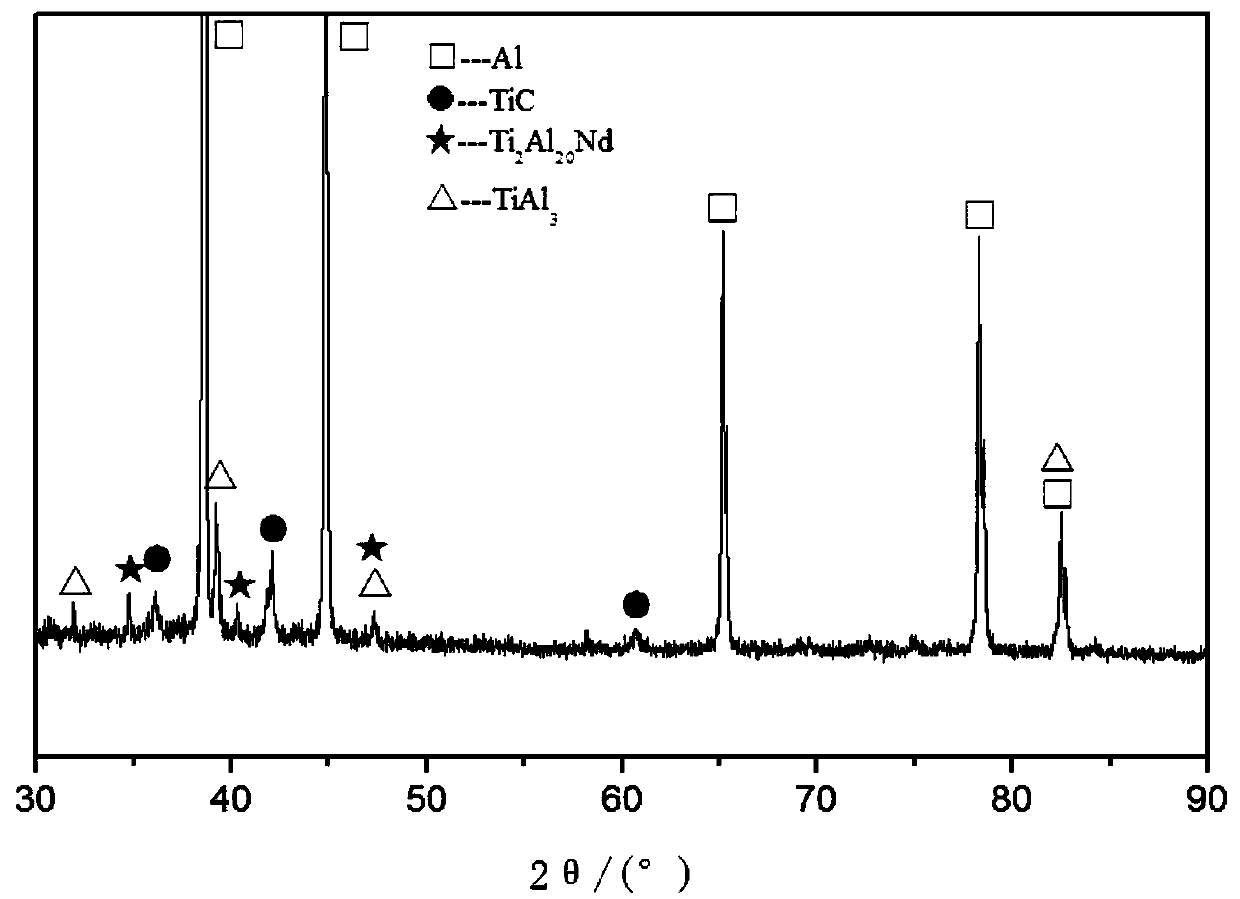

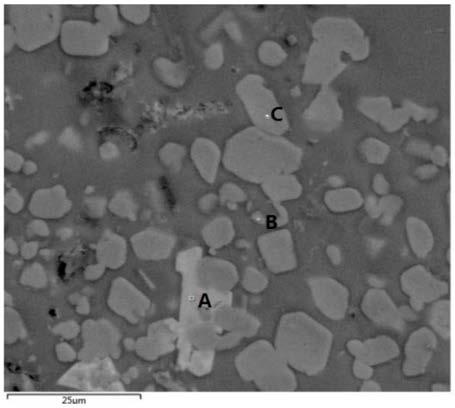

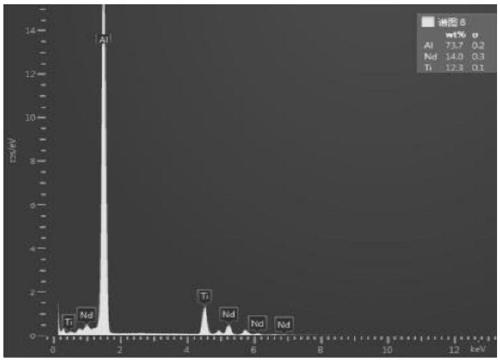

[0067] Aluminum powder with a particle size of 250 mesh, titanium powder with a particle diameter of 350 mesh, graphite powder with a particle diameter of 440 mesh and Nd powder with a particle diameter of 320 mesh 2 o 3 The powder was mixed in a planetary ball mill at a rate of 600 rpm for 90 minutes according to a ratio of 5:2:1 to obtain a mixed powder, which was then compressed into a mixed powder block with a diameter of 25 mm under a pressure of 50;

[0068] Heat the aluminum ingot to 800°C to completely melt the aluminum ingot to obtain an aluminum melt;

[0069] According to the proportion of Ti mass content in the master alloy obtained after the reaction is 5%, the mixed powder block is pressed into the aluminum melt at 800 ° C, and the thermal explosion reaction is carried out for 3 minutes, and then the alloy melt is allowed to stand at 800 ° C for 4 minutes, Then stir for 1 min at a rate of 1 min / time to obtain an alloy melt;

[0070] Adding 1.5% C to the alloy m...

Embodiment 2

[0076] Heating industrial pure aluminum to 730°C to remove slag after it is completely melted;

[0077] Add the Al-Ti-C-Nd master alloy prepared in Example 1 into the molten aluminum at a ratio of 0.2% by weight, stir for 1 min at a rate of 1 min / time, and then keep it warm for 5 min before casting at 730°C to obtain a refinement effect Good pure aluminum.

[0078] Carry out microstructure observation to the pure aluminum after present embodiment refinement, obtain picture as Figure 6 It can be seen from the figure that the structure is a fine equiaxed crystal structure with a size of 150-180 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com