WOLED device

A device and light-emitting layer technology, applied in the field of flat-panel displays, can solve the problems of limited efficiency of WLOED devices and low efficiency of WOLED devices, and achieve the effect of improving utilization rate and luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

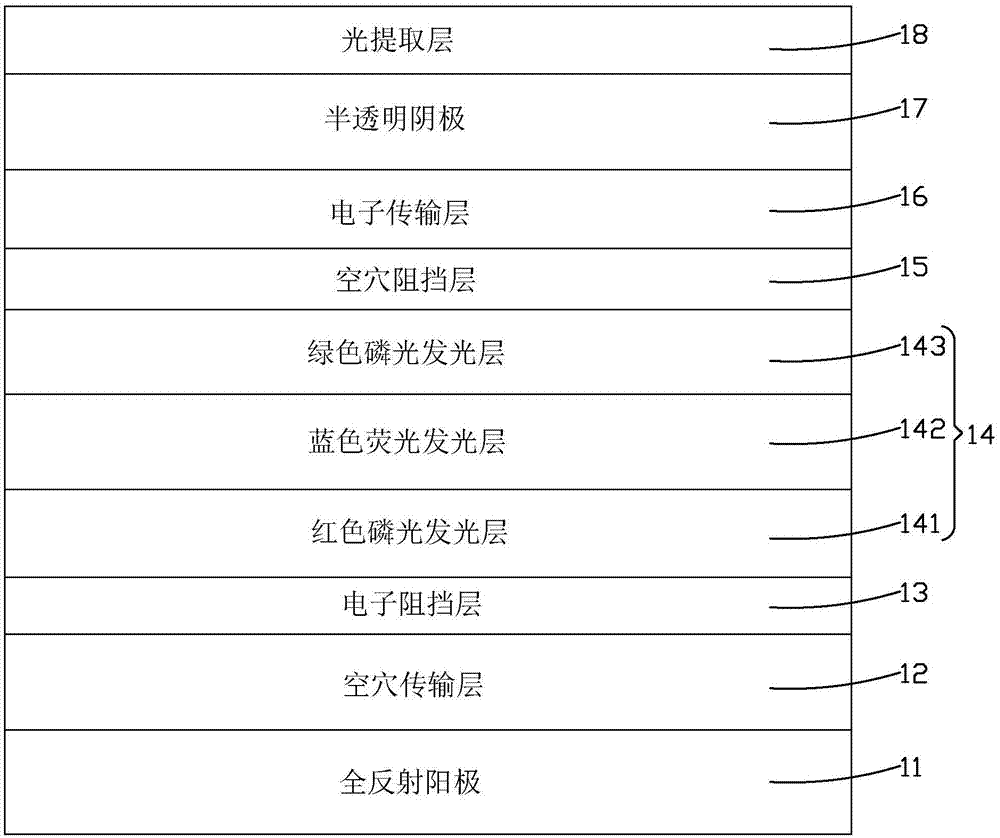

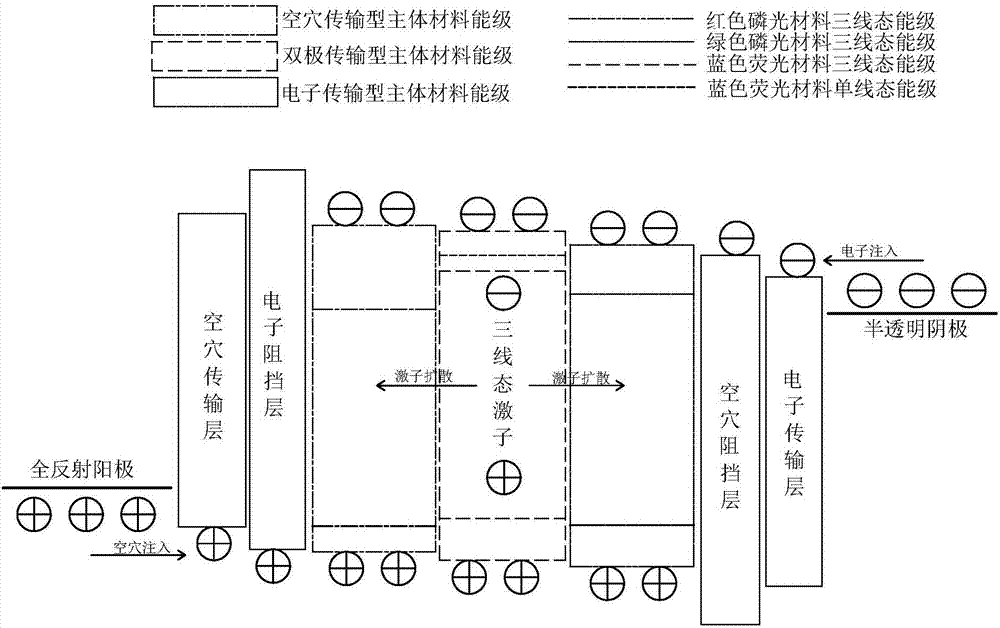

[0027] see figure 1 , the present invention provides a WOLED device, comprising a total reflection anode (Total Reflection Anode) 11, a hole transport layer (Hole Transport Layer) 12, an electron blocking layer (Electron Blocking Layer) 13, a red phosphorescent Red Phosphorescent EML 141, Blue Fluorescent EML 142, Green Phosphorescent EML 143, Hole Blocking Layer 15, Electron Transport Layer ) 16 and semi-transparent cathode (Semi transparent Cathode) 17.

[0028] Wherein, the red phosphorescent emitting layer 141, the blue fluorescent emitting layer 142 and the green phosphorescent emitting layer 143 jointly constitute the white emitting layer 14; the red phosphorescent emitting layer 141, the blue fluorescent emitting layer 142 and the gree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com