Limestone powder slurry making slurry system and slurry making method thereof

The technology of limestone powder and limestone is applied in the desulfurization pulping system of thermal power plant, the slurry system of limestone powder pulping and its pulping field, which can solve the problems of high fineness of milled limestone powder, long start-up time and high equipment energy consumption. , to reduce daily costs, start quickly, and reduce project costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further specifically described below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0023] Example.

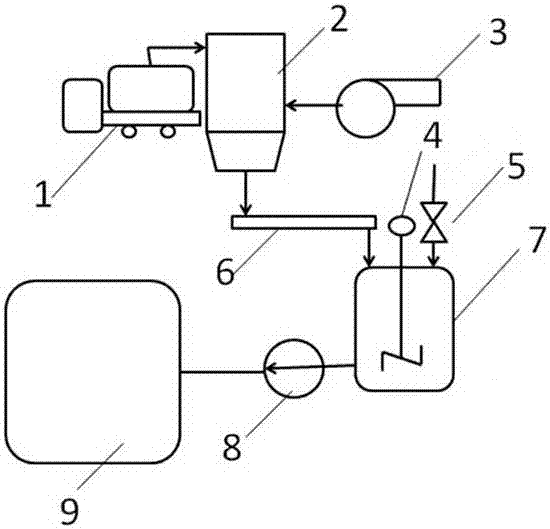

[0024] see figure 1 , the invention discloses a limestone powder slurry system. In this embodiment, a limestone powder slurry system includes a limestone powder bin 2, a fluidization fan 3, a limestone powder feeder 6, and a limestone powder Slurry tank 7, limestone powder slurry tank agitator 4, slurry supply pump 8 and absorption tower 9, the limestone powder bin 2 is equipped with a material level gauge, the top of the limestone powder bin 2 is connected with a powder inlet pipe, and the limestone powder tanker 1 Convey lime powder to the limestone powder bin 2 through compressed air from the powder inlet pipe. The interior of the limestone powder bin 2 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com