Modified hydrodechlorination catalyst for producing high-purity chloroacetic acid and preparation method thereof

A hydrodechlorination and catalyst technology, which is applied in the preparation of carboxylate, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of strict preparation conditions and operation, and achieve good selectivity. , stable performance, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

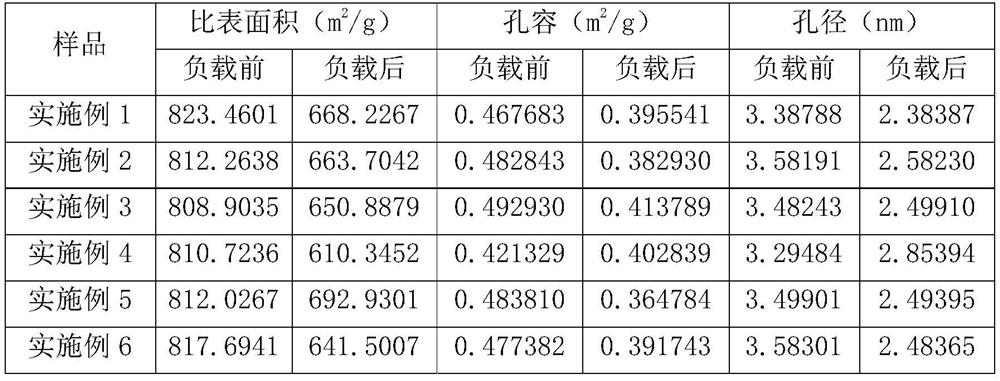

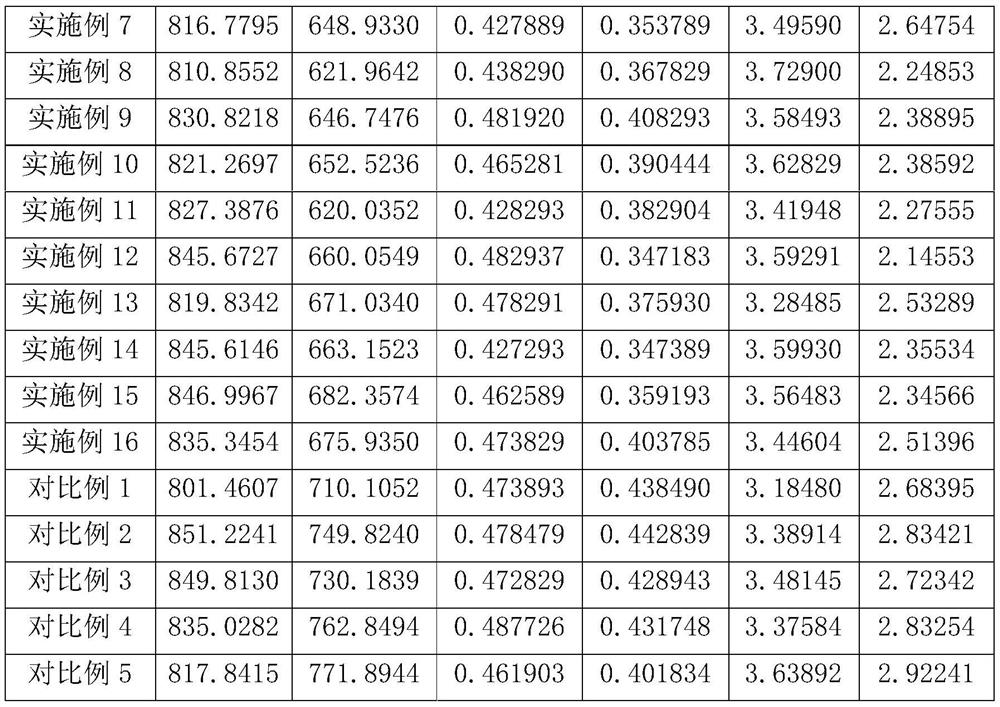

Embodiment 1

[0080] This embodiment prepares a modified hydrodechlorination catalyst for high-purity chloroacetic acid, which is composed of the following components: the metal active component elemental palladium accounts for 0.5% of the overall mass percentage of the catalyst, and the metal additive elemental zirconium accounts for 2.0% of the overall mass percentage of the catalyst. , and the balance is activated carbon carrier.

[0081] The preparation method of the modified hydrodechlorination catalyst of the present embodiment is:

[0082] Step 1: Weigh the activated carbon carrier and pour it into nitric acid solution as the pickling solution for pickling. The concentration of the pickling solution is 1.0mol / L, heat in a water bath at 80°C for 4 hours, and then wash with deionized water until the solution is neutral , dried at 120°C for 5 hours;

[0083] Step 2: Add the activated carbon carrier initially treated in step 1 into the zirconium salt solution, where the concentration of...

Embodiment 6

[0089] This embodiment prepares a modified hydrodechlorination catalyst for high-purity chloroacetic acid, which is composed of the following components: the metal active component elemental palladium accounts for 1.0% of the overall mass percentage of the catalyst, and the metal additive elemental zirconium accounts for 1.5% of the overall mass percentage of the catalyst. , and the balance is activated carbon carrier.

[0090] The preparation method of the modified hydrodechlorination catalyst of the present embodiment is:

[0091] Step 1: Weigh the activated carbon carrier and pour it into nitric acid solution as the pickling solution for pickling. The concentration of the pickling solution is 1.0mol / L, heat in a water bath at 80°C for 4 hours, and then wash with deionized water until the solution is neutral , dried at 120°C for 5 hours;

[0092] Step 2: Add the activated carbon carrier initially treated in step 1 into the zirconium salt solution, where the concentration of...

Embodiment 11

[0098] This embodiment prepares a modified hydrodechlorination catalyst for high-purity chloroacetic acid, which consists of the following components: the metal active component elemental palladium accounts for 1.0% of the overall mass percentage of the catalyst, and the metal promoter zirconium accounts for 2.0% of the overall mass percentage of the catalyst. The balance is activated carbon carrier.

[0099] The preparation method of the modified hydrodechlorination catalyst of the present embodiment is:

[0100] Step 1: Weigh the activated carbon carrier and pour it into nitric acid solution as the pickling solution for pickling. The concentration of the pickling solution is 0.5mol / L, heat in a water bath at 80°C for 4 hours, and then wash with deionized water until the solution is neutral , dried at 120°C for 5 hours;

[0101] Step 2: Add the activated carbon carrier initially treated in step 1 into the zirconium salt solution, where the concentration of the zirconium salt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com