Regeneration and purification process of recyclable silicon material in photovoltaic industry chain

An industrial chain and silicon material technology, which is applied in the field of recycling and purification of recyclable silicon material in the photovoltaic industry chain, can solve the problems of inability to process recycled silicon material, unstable battery, and high decay rate, and achieve rapid separation, improve utilization, and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The regeneration and purification process of reusable silicon material includes the following steps:

[0060] (1) Classification and cleaning

[0061] The silicon material recovered from the photovoltaic industry chain was screened with a resistance tester and manual cooperation, and the silicon material with a resistivity between 0.5 and 3Ω·cm was screened.

[0062] The above-mentioned selected silicon material is opened, the surface is mechanically polished, and the thickness of the surrounding and bottom skin is 0.1-8 mm, and the thickness of the top skin is 0.2-10 mm.

[0063] With volume ratio of 5:1:1 30wt% sulfuric acid, 28wt% H 2 O 2 The silicon material was soaked in a mixture of water and water for 15 minutes, and then 25wt% ammonia water and 28wt% H were used in a volume ratio of 5:1:1. 2 O 2 Soak in a mixture of water and water for 15 minutes.

[0064] The silicon material is re-cleaned by pure water through ultrasonic cleaning technology, and finally v...

Embodiment 2

[0074] This embodiment is basically the same as Embodiment 1, the difference is:

[0075] (1) In the classification and cleaning step, the silicon material with resistivity < 0.5 Ω·cm is screened out.

[0076] (2) The treatment time of the smelting and impurity removal process is 12h, and the amount of the electrophoresis agent added is 1 / 100 of the weight of the silicon material.

[0077] (3) The time for vacuum overflow, impurity removal, blowing and cooling treatment is 12h.

[0078] In this embodiment, the yield rate of silicon material that meets the solar-grade polysilicon standard is 71%.

Embodiment 3

[0080] This embodiment is basically the same as Embodiment 1, the difference is:

[0081] (1) The classification and cleaning step screen out the silicon material with resistivity > 3 Ω·cm.

[0082] (2) The treatment time of the smelting and impurity removal process is 4h, and the amount of the electrophoresis agent added is 1 / 400 of the weight of the silicon material.

[0083] (3) The time for vacuum overflow, impurity removal, blowing and cooling treatment is 4h.

[0084] In this embodiment, the yield rate of silicon material that meets the solar-grade polysilicon standard is 76%.

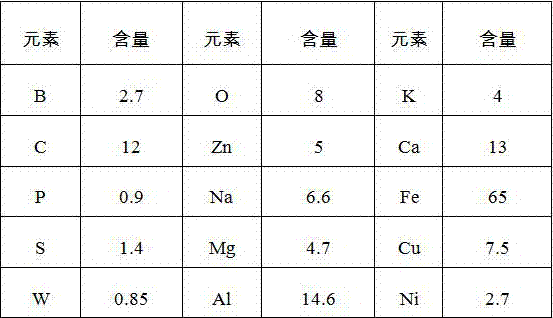

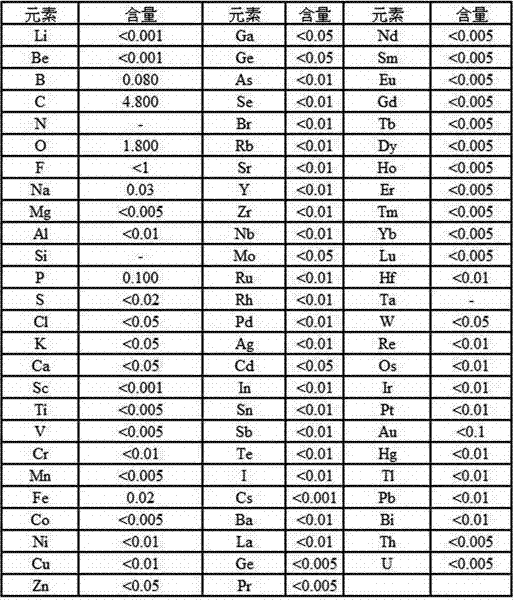

[0085] Table 1 and Table 2 show the content of impurity elements before and after the silicon material in Example 2 is purified.

[0086] Table 1 Content of polysilicon impurity elements before purification (ppmWt)

[0087]

[0088] Table 2 Purified polysilicon impurity element content (ppmWt)

[0089]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com