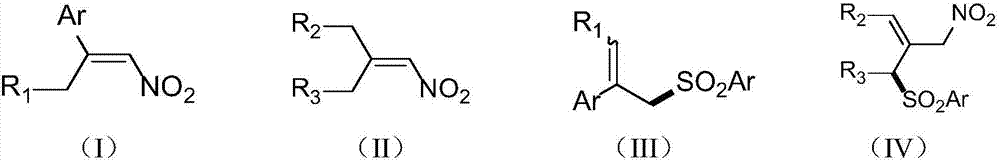

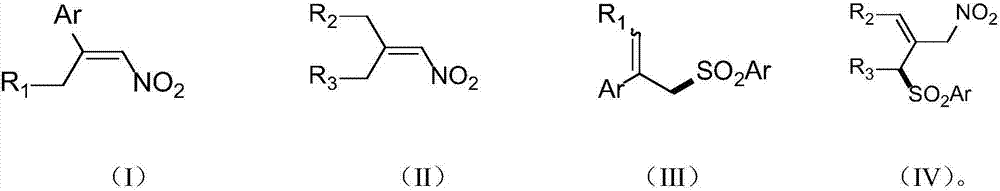

Method for selectively synthesizing allylic sulfone compound by utilizing nonmetal catalyst

A non-metallic catalyst and allyl sulfone technology, which is applied in the field of selective synthesis of allyl sulfone compounds, can solve the problems of difficult operation, long reaction time, unstable raw materials, etc., and achieve the effect of shortening the reaction time and increasing the rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The specific steps are: add 0.3mmol 1-nitro-2-phenylpropene, 0.4mmol sodium benzenesulfinate, 0.03mmol I 2 , 0.6mmol TBHP and 3mL DMSO, after magnetically stirring at 80°C for 3 hours, the reaction solution was extracted with ethyl acetate, the organic layer was washed with saturated brine, dried over anhydrous sodium sulfate, and the solvent was evaporated under reduced pressure to obtain the crude product. The crude product was purified by column separation with ethyl acetate / petroleum ether=1:10 / V as the eluent to obtain the desired product as a white solid with a yield of 88%.

[0023] The proton nuclear magnetic spectrogram result of gained product is: 1 H NMR (600MHz, CDCl 3 ,ppm)δ7.77(d,J=7.8Hz,2H),7.52(t,J=7.2Hz,1H),7.40(t,J=7.8Hz,2H),7.27–7.20(m,5H), 5.57(s,1H), 5.20(s,1H), 4.26(s,2H).

Embodiment 2

[0025] The specific steps are: add 0.3mmol 1-nitro-2-phenylpropene, 0.35mmol sodium p-methoxybenzenesulfinate, 0.06mmolTBAI, 0.3mmol K to a 50mL round bottom flask 2 S 2 o 8 and 3mL DMF, stirred and reacted with magnetic force at 100°C for 3 hours, extracted the reaction solution with ethyl acetate, washed the organic layer with saturated brine, dried over anhydrous sodium sulfate, and evaporated the solvent under reduced pressure to obtain the crude product. Ethyl acetate / petroleum ether=1:15 / V was used as the eluent for column separation and purification to obtain the desired product, which was a white solid with a yield of 92%.

[0026] The proton nuclear magnetic spectrogram result of gained product is: 1 H NMR (600MHz, CDCl 3 ,ppm)δ7.67(d,J=9.0Hz,2H),7.26–7.20(m,5H),6.85(d,J=9.0Hz,2H),5.57(s,1H),5.19(s,1H ), 4.23(s,2H), 3.80(s,3H).

Embodiment 3

[0028] The specific steps are: add 0.3mmol 1-nitro-2-(4-bromophenyl)propene, 0.44mmol sodium p-methoxybenzenesulfinate, 0.06mmolI 2 , 0.3mmol TBHP and 3mL DMSO, reacted with magnetic stirring at 80°C for 2.5 hours, extracted the reaction solution with ethyl acetate, washed the organic layer with saturated brine, dried over anhydrous sodium sulfate, evaporated the solvent under reduced pressure to obtain the crude product, The crude product was purified by column separation with ethyl acetate / petroleum ether=1:10 / V as the eluent to obtain the desired product, which was a white solid with a yield of 87%.

[0029] The proton nuclear magnetic spectrogram result of gained product is: 1 H NMR (400MHz, CDCl 3 ,ppm)δ7.71(d,J=8.8Hz,2H),7.30–7.26(m,2H),7.00–6.89(m,4H),5.55(s,1H),5.20(s,1H),4.24 (s,2H), 3.87(s,3H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com