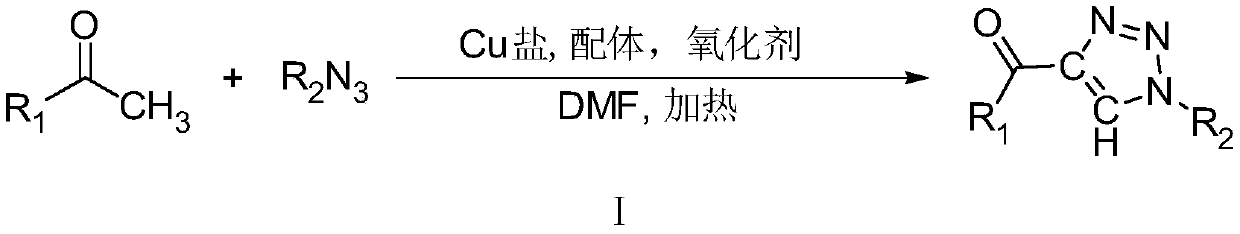

One-pot method for synthesizing 4-acetyl-1,2,3-triazole compounds

A technology of a triazole compound and a synthesis method, which is applied in directions such as organic chemistry, can solve the problems of harsh reaction conditions, difficult synthesis, expensive catalysts, etc., and achieves the effects of mild reaction conditions, a wide range of substrates, and low-cost catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

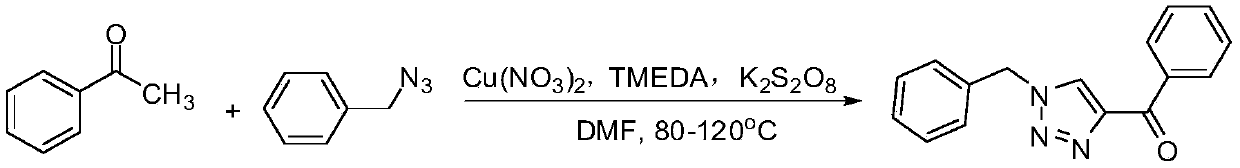

[0021] Synthesis of (N-benzyl-1,2,3-triazole-4-substituted) (phenyl)methanone, the reaction formula is:

[0022]

[0023] The specific steps are: add 0.33mmol acetophenone, 0.50mmol benzyl azide, 0.09mmol Cu(NO 3 ) 2 , 1 mmol K 2 S 2 O 8 , 0.09mmol TMEDA, 3mL DMF, magnetically stirred at 110°C for 5 hours, extracted the reaction solution with ethyl acetate, washed the organic layer with saturated brine, dried over anhydrous sodium sulfate, evaporated the solvent under reduced pressure to obtain crude The product, the crude product was purified by column separation and purification with ethyl acetate / petroleum ether=1:5 (V / V) as the eluent to obtain the desired product, which was a white solid with a yield of 80%.

[0024] The proton nuclear magnetic spectrogram result of gained product is: 1 H NMR (600MHz, CDCl 3 )δ8.46–8.39(m,1H),8.17(s,1H),7.61(m,J=10.8,3.9Hz,1H),7.51(t,J=7.8Hz,1H),7.40(d,J =6.9Hz,1H),7.33(d,J=7.5Hz,1H),5.60(s,1H).

Embodiment 2

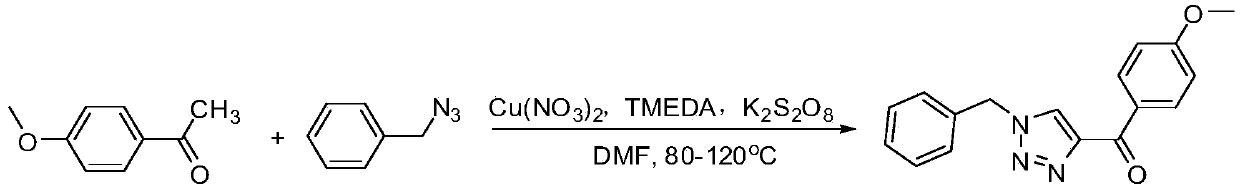

[0026] (N-benzyl-1,2,3-triazole-4-substituted) (4-methoxyphenyl) ketone synthesis, the reaction formula is:

[0027]

[0028] The specific steps are: add 0.33mmol 4-methoxyacetophenone, 0.50mmol benzyl azide, 0.09mmol Cu(NO 3 ) 2 , 1 mmol K 2 S 2 O 8 , 0.09mmol TMEDA, 3mL DMF, magnetically stirred at 110°C for 5 hours, extracted the reaction solution with ethyl acetate, washed the organic layer with saturated brine, dried over anhydrous sodium sulfate, evaporated the solvent under reduced pressure to obtain crude The product, the crude product was purified by column separation and purification with ethyl acetate / petroleum ether=1:5 (V / V) as the eluent to obtain the desired product, which was a white solid with a yield of 85%.

[0029] The proton nuclear magnetic spectrogram result of gained product is: 1 H NMR (600MHz, CDCl 3 )δ8.34(d, J=8.1Hz, 2H), 8.16(s, 1H), 7.33(m, 7H), 5.59(s, 2H), 3.41(s, 3H).

Embodiment 3

[0031] (N-benzyl-1,2,3-triazole-4-substituted) (4-fluorophenyl) ketone synthesis, the reaction formula is:

[0032]

[0033] The specific steps are: add 0.33mmol 4-fluoroacetophenone, 0.50mmol benzyl azide, 0.09mmol Cu(NO 3 ) 2 , 1 mmol K 2 S 2 O 8 , 0.09mmol TMEDA, 3mL DMF, magnetically stirred at 110°C for 5 hours, extracted the reaction solution with ethyl acetate, washed the organic layer with saturated brine, dried over anhydrous sodium sulfate, evaporated the solvent under reduced pressure to obtain the crude The product, the crude product was purified by column separation and purification with ethyl acetate / petroleum ether=1:5 (V / V) as the eluent to obtain the desired product, which was a white solid with a yield of 87%.

[0034] The proton nuclear magnetic spectrogram result of gained product is: 1 H NMR (600MHz, CDCl 3 )δ8.53(m,2H),8.18(s,1H),7.45–7.31(m,5H),7.21–7.14(m,2H),5.61(s,2H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com