Nondestructive detecting device and method for mandrels of carbon fiber composite core wires

A non-destructive testing and wire core technology, which is applied to measuring devices, instruments, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc. It can solve problems such as difficulties in the detection of wire mandrels, hidden dangers in the stable use of transmission lines, and imperfect construction procedures. Achieve the effects of easy popularization, strong practicability, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Use this equipment to carry out non-destructive testing on the carbon fiber composite material wire mandrel, the specific implementation method is as follows:

[0034] (1) Fix the mandrel made of composite material on the positioning test bench to ensure that the radiation end of the excitation probe, the part to be tested of the test mandrel sample, and the receiving end of the signal pickup probe are on the same horizontal line;

[0035](2) Turn on the power supply of the excitation probe and the power supply of the signal pickup probe, emit a sound wave signal with a specific frequency of 1000 Hz, open the signal comparison analysis software of the oscillation signal analyzer, and record the sound wave transmission signal at different positions for the specific mandrel sample;

[0036] (3) After the transmitted acoustic wave signal is recorded, use the signal comparison analysis software to compare and analyze the digital signal spectrum of the standard non-defective ...

Embodiment 2

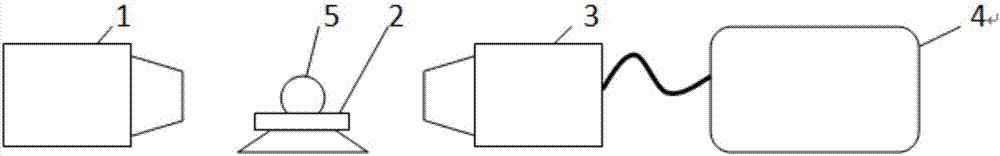

[0038] A non-destructive testing device for a carbon fiber composite core wire mandrel, comprising: an excitation probe 1, a wire positioning device 2, an oscillation signal pickup probe 3, an oscillation signal analyzer 4, the excitation probe 1, a wire positioning device 2, an oscillation The signal pickup probe 3 and the oscillation signal analyzer 4 are arranged in sequence, and the vibration wave emitted by the excitation probe 1 transmits a specific frequency through the carbon fiber composite core wire mandrel arranged on the wire positioning device 2, and then transmits to the oscillation signal pickup probe 3. The oscillation signal pickup probe 3 is connected to an oscillation signal analyzer 4 .

Embodiment 3

[0040] A non-destructive testing device for a carbon fiber composite core wire mandrel, comprising: an excitation probe 1, a wire positioning device 2, an oscillation signal pickup probe 3, an oscillation signal analyzer 4, the excitation probe 1, a wire positioning device 2, an oscillation The signal pickup probe 3 and the oscillation signal analyzer 4 are arranged in sequence, and the vibration wave emitted by the excitation probe 1 transmits a specific frequency through the carbon fiber composite core wire mandrel arranged on the wire positioning device 2, and then transmits to the oscillation signal pickup probe 3. The oscillation signal pickup probe 3 is connected to an oscillation signal analyzer 4 .

[0041] The frequency of the vibration wave is in the range of 100-100000 Hz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com