Energy-sensitive resin composition

A resin composition, sensitive technology, applied in the direction of instruments, optics, optomechanical equipment, etc., can solve the problems of inapplicability, heat resistance, etc., and achieve excellent tensile elongation and chemical resistance, dielectric constant low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0739]

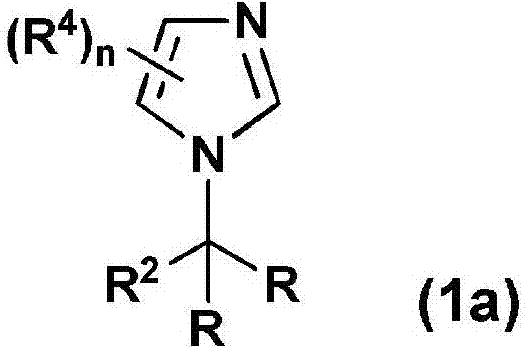

[0740] The method for preparing the energy-sensitive resin composition according to the present invention is not particularly limited. For example, it can be prepared by blending the following components: as the resin precursor component (B), selected from the various monomer components described above and at least one of the group consisting of a precursor polymer; a solvent (S); an imidazole compound (A); and the above-mentioned other components added as necessary.

[0741] Both a monomer component and a precursor polymer can be mix|blended as a resin precursor component (B), Usually, only a monomer component or only a precursor polymer is sufficient. From the viewpoint that the molecular weight of the ring-forming polymer can be increased in the presence of the imidazole compound (A) as described later, it is preferable to synthesize Cycloforming polymers.

[0742] Moreover, it is preferable to mix|blend a precursor polymer as (B) component from a viewpoint whic...

Embodiment 1~27、 comparative example 1~14

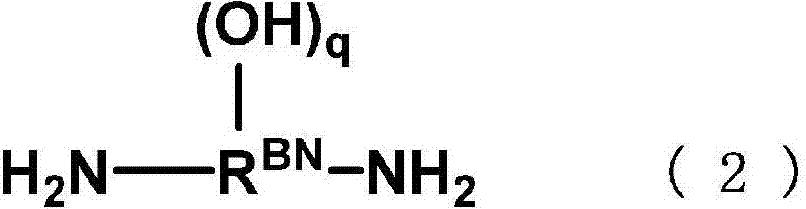

[0796] In Examples and Comparative Examples, the following diamine compound (2b), carboxylic anhydride, diamine diol, dicarbonyl compound, solvent, imidazole compound (A) and comparative compound were used.

[0797] ・Diamine compound (2b)

[0798] DA1: ODA: 4,4’-diaminodiphenyl ether

[0799] DA2: PPD: p-phenylenediamine

[0800] DA3: MPD: m-phenylenediamine

[0801] DA4: 2,4-TDA: 2,4-diaminotoluene

[0802] DA5: BAFL: 9,9-bis(4-aminophenyl)fluorene

[0803] DA6: BTFL: 9,9-bis(4-amino-3-methylphenyl)fluorene

[0804] DA7: BisA-P: 4,4’-[1,4-phenylenebis(1-methylethane-1,1-diyl)]diphenylamine

[0805] DA8: MDA: 4,4'-Diaminodiphenylmethane

[0806] [chemical formula 82]

[0807]

[0808] DA9: 2,2-bis[4-(4-aminophenoxy)phenyl]propane

[0809]DA10: 1,4-bis(4-amino-α,α-dimethylbenzyl)benzene

[0810] DA11: 1-(4-aminophenyl)-1,3,3-trimethyl-1H-inden-5-amine

[0811] DA12: 2,2-bis[4-(4-aminophenoxy)phenyl]hexafluoropropane

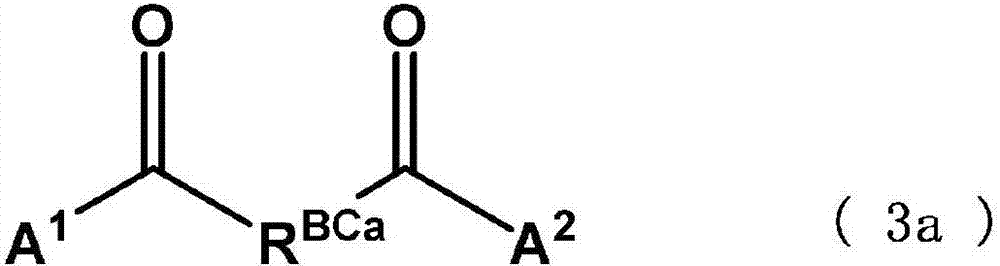

[0812] ·Carboxylic anhydride

[0813] TC1: PM...

Embodiment 1~25

[0869] To the solution of the imide ring and / or oxazole ring-forming polymer obtained in each preparation example, any one of compounds 1 to 5 was added in the amount described in Table 1 and stirred to prepare an energy-sensitive resin combination.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com