Wafer cutting device and method for jet assisted laser plasma

A plasma and auxiliary laser technology is applied in the field of ion cutting device and ion plasma directional cutting device, which can solve the problems of easily destroying the functional structure of the chip and being unable to adapt to the chip cutting process, so as to improve economic benefits, reduce thermal effects, and simplify The effect of the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit this invention.

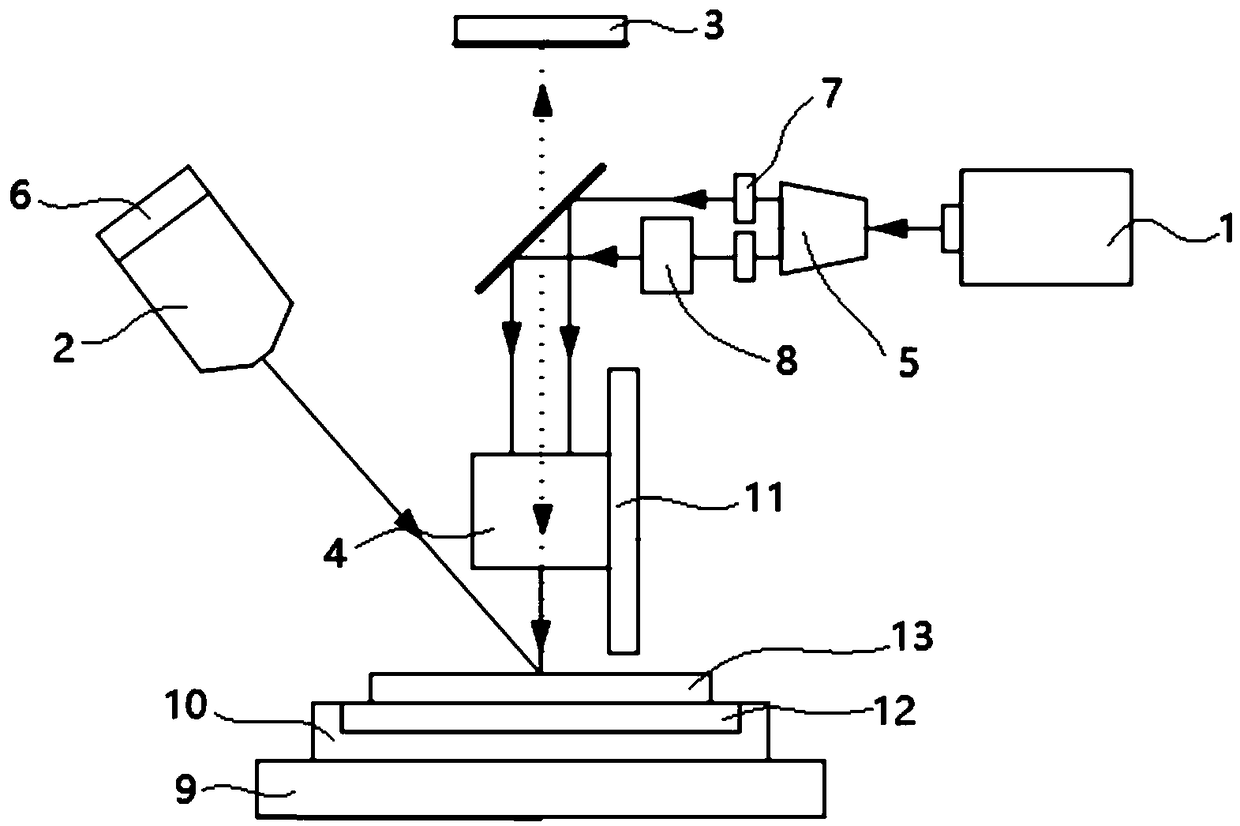

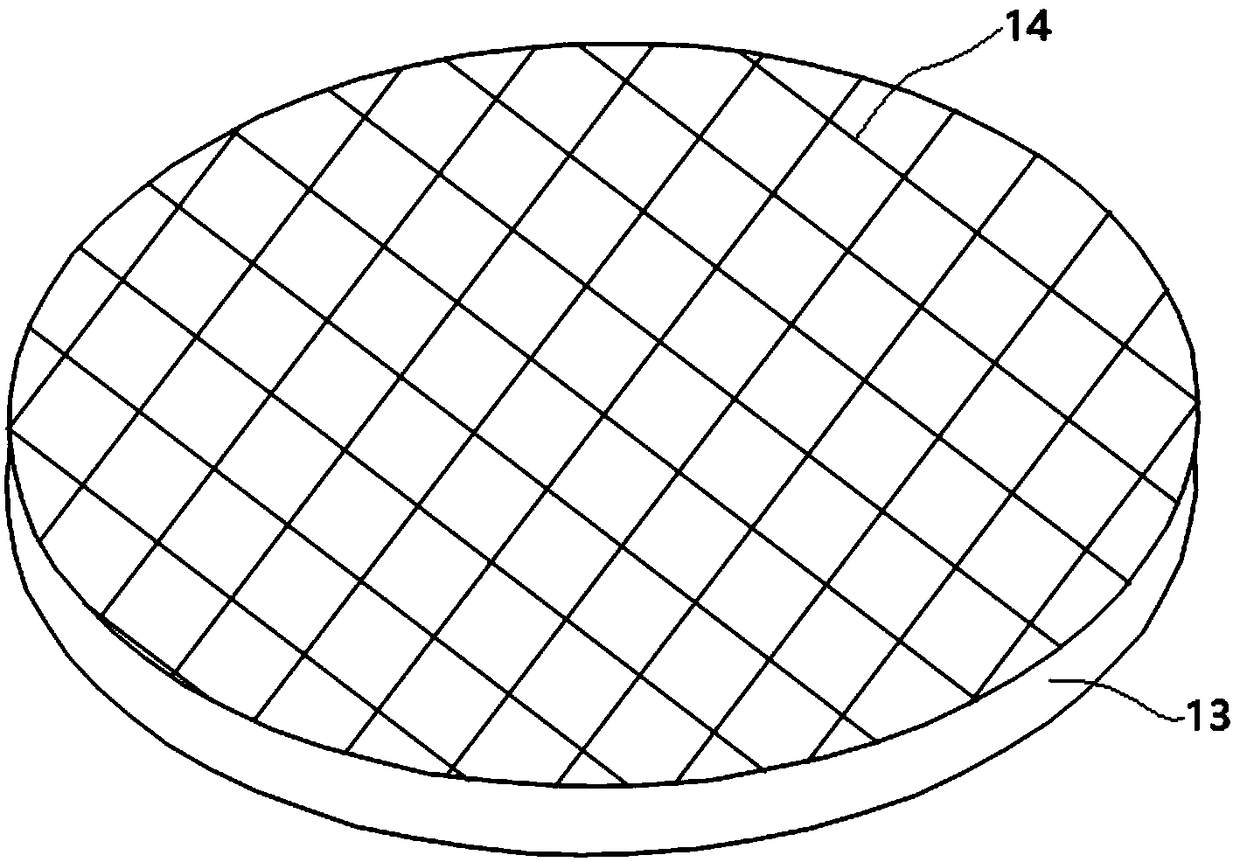

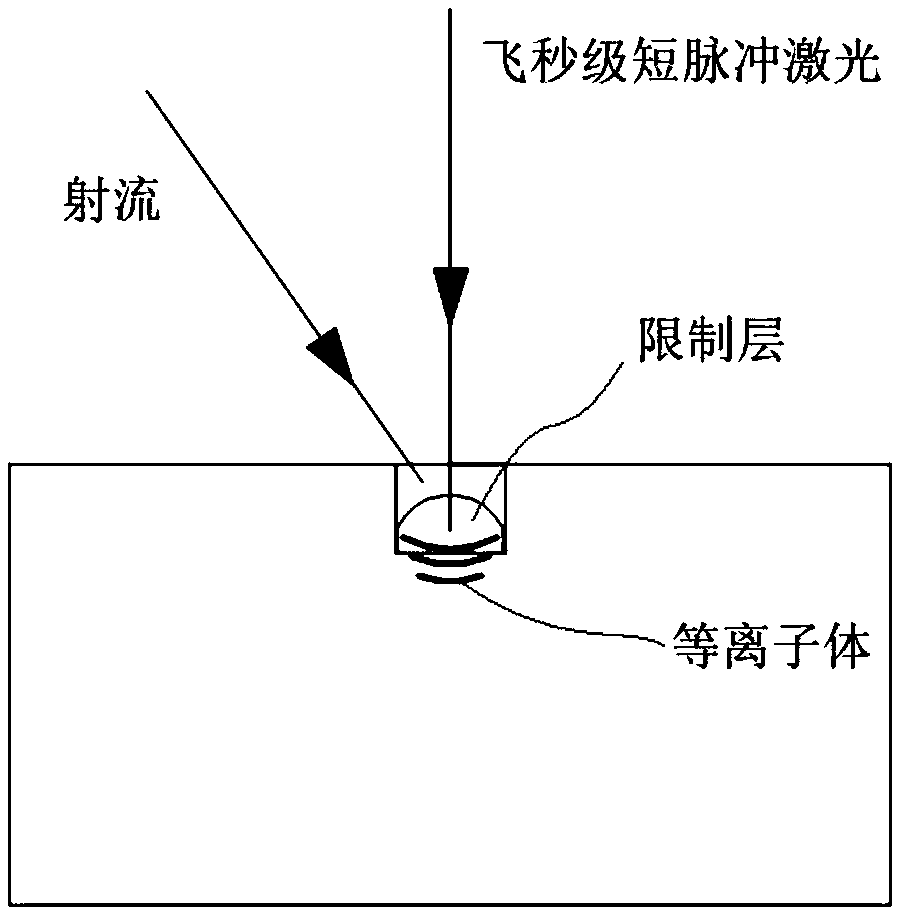

[0048] please see figure 1 and figure 2 A jet-assisted laser plasma wafer cutting device provided by the present invention includes a femtosecond laser 1, a jet-assisted system 2, a CCD imaging system 3, a focusing lens group 4, a beam splitting lens 5, a rotating device 6, and a shutter 7 , Triple frequency device 8, processing platform and control system; the rotating device 6 has two degrees of freedom, installed on the nozzle in the jet auxiliary system 2, and completes the adjustment of the jet direction under the control of the control system; the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com