Metathesis catalyst and process for producing olefin

A technology for metathesis catalysts and olefins, applied in molecular sieve catalysts, chemical instruments and methods, including molecular sieve catalysts, etc., can solve problems such as reducing the yield of propylene products, and achieve the effects of prolonging catalyst life and long reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The object of the present invention is further achieved by the metathesis catalyst of the present invention, which is obtainable by the following preparation method, the preparation method comprising: a) mixing an inorganic carrier with a zeolite to obtain their mixture; b) mixing an inorganic carrier with a zeolite; depositing a transition metal on a mixture of zeolites to obtain a deposited mixture; and c) mixing the deposited mixture with a layered double hydroxide to obtain a metathesis catalyst.

[0034] Mixtures of inorganic supports and zeolites can be readily obtained by physical mixing. Metal deposition techniques may be conventional in the art without limitation. Typically, a transition metal compound is impregnated on a mixture of an inorganic support and a zeolite.

[0035] In a specific embodiment, the metal deposition mixture is dried and / or calcined prior to mixing with the layered double hydroxide. Drying and calcination methods are not particularly li...

Embodiment 1

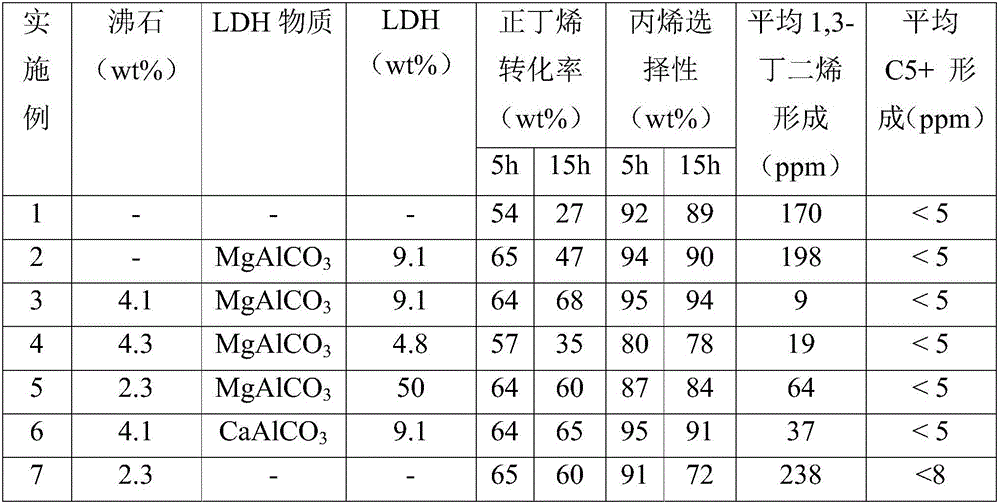

[0044] Example 1 [Compare]

[0045] The WO containing 9wt% on the silica support 3 The metathesis catalyst was loaded into a tubular reactor. Take 1.4hr -1 A feed stream comprising ethylene and 2-butene was fed to the reactor and the catalyst bed was controlled at 350 °C and 22 bar gauge pressure at a weight hourly space velocity (WHSV).

[0046] The effluent from the reactor was analyzed. At 5 hours on stream, the n-butene conversion was 54% and the propylene selectivity was 92%. At 15 hours on stream, the n-butene conversion was 27% and the propylene selectivity was 89%. The average 1,3-butadiene formation was 170 ppm and the average C5+ formation was less than 5 wt% relative to the total effluent stream.

Embodiment 2

[0047] Example 2 [Compare]

[0048] By adding 9wt% WO on the silica support at a weight ratio of 10:1 3 with Mg-Al-CO 3 Layered double hydroxides are physically mixed to give metathesis catalysts. The catalyst was loaded into the tubular reactor. Take 1.4hr- 1 A feed stream comprising ethylene and 2-butene was fed to the reactor and the catalyst bed was controlled at 350 °C and 22 bar gauge pressure at a weight hourly space velocity (WHSV).

[0049] The effluent from the reactor was analyzed. At 5 hours on stream, the n-butene conversion was 65% and the propylene selectivity was 94%. At 15 hours on stream, the n-butene conversion was 47% and the propylene selectivity was 90%. The average 1,3-butadiene formation was 198 ppm and the average C5+ formation was less than 5 wt% relative to the total effluent stream.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com