Centrifugal separation method of titanium isotopes

A titanium isotope and centrifugal separation technology, applied in the field of isotope separation and preparation, can solve the problems of high product price, high energy consumption, low output, etc., and achieve the effects of large separation coefficient, low energy consumption, and technical feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

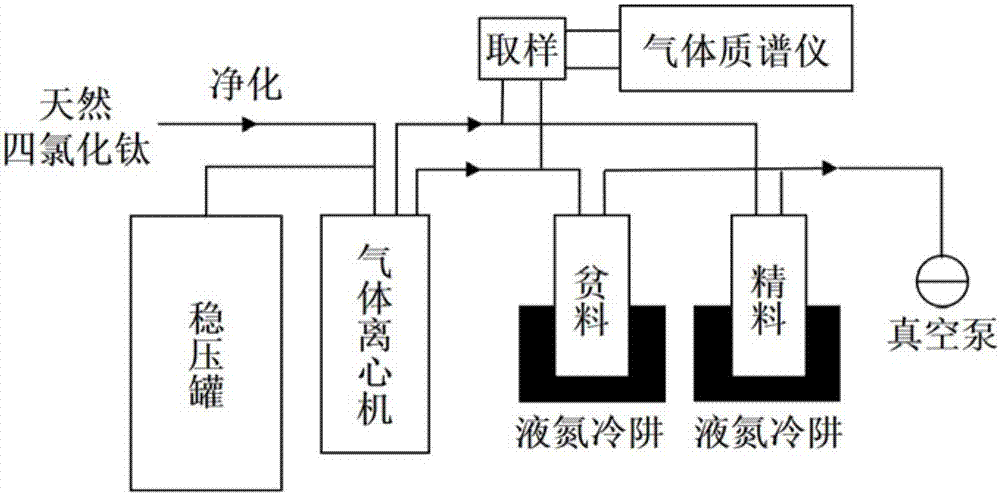

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] For the separation of titanium isotopes by gas centrifugation, the selection of a suitable working medium is the key element. The working medium of gas centrifugation should generally meet the following three conditions:

[0014] 1) It remains stable at temperatures below 300°C and does not decompose

[0015] 2) The relative molecular mass is not less than 70

[0016] 3) At room temperature, the saturated vapor pressure is not less than 665Pa

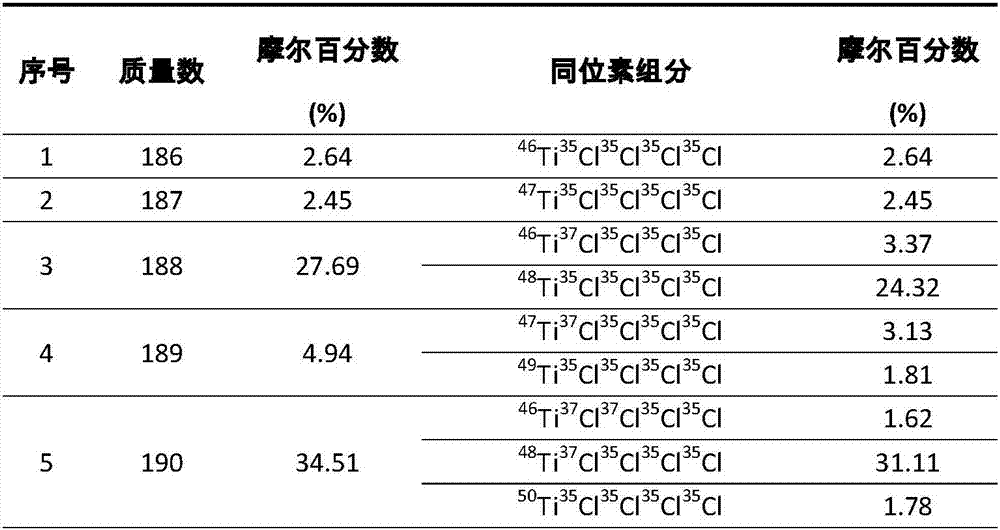

[0017] Natural titanium tetrachloride (TiCl 4 ) has a relative molecular mass of 189.71, is difficult to pyrolyze, and has a saturated vapor pressure of about 1330Pa at room temperature, which meets the requirements of the gas centrifugation method for the working medium. It is an important intermediate, so it is easy to obtain and low in cost, which is also the advantage of choosing it as a working medium. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com