Method for preparing water treatment filtering membrane

A technology of water treatment and membrane filtration, which is applied in water/sewage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc. It can solve the problem of poor stability of nanofiltration functional layer and no large-scale mature products , low water production and other issues, to achieve uniform and stable nanofiltration functional layer, to achieve continuous industrial production, and to achieve the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

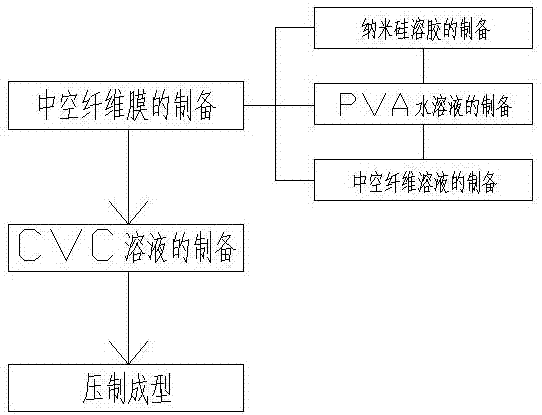

[0024] A method for preparing a water treatment membrane, through the preparation of a hollow fiber membrane, the preparation of a CMC solution and the pressing and molding steps, the preparation of a water treatment membrane is completed; the specific steps are as follows:

[0025] (1) Preparation of hollow fiber membrane:

[0026] a. Preparation of nano-silica sol: Mix tetraethoxysilane, titanium dioxide particles, absolute ethanol and deionized water into a beaker, then stir in a water bath at 70°C for 20 minutes, then add dropwise ammonia water with a mass fraction of 15% 0.1g, prepared nano-silica sol after keeping it in a water bath at 50°C for 4 hours, the mixing ratio of tetraethoxysilane, titanium dioxide particles, absolute ethanol and deionized water is 3:1:8:1;

[0027] b. Preparation of PVA aqueous solution: wash, dry and weigh a 1000ml beaker to obtain mass m1, then add 760g deionized water into the beaker, add it in a 97°C constant temperature water bath, stir, ...

Embodiment 2

[0033] A method for preparing a water treatment membrane, through the preparation of a hollow fiber membrane, the preparation of a CMC solution and the pressing and molding steps, the preparation of a water treatment membrane is completed; the specific steps are as follows:

[0034] (1) Preparation of hollow fiber membrane:

[0035] a. Preparation of nano-silica sol: Mix tetraethoxysilane, titanium dioxide particles, absolute ethanol and deionized water into a beaker, then stir in a 70°C water bath for 25 minutes, and then add dropwise ammonia water with a mass fraction of 15% 0.4g, prepared nano-silica sol after keeping it in a water bath at 50°C for 4 hours, the mixing ratio of tetraethoxysilane, titanium dioxide particles, absolute ethanol and deionized water is 5:1:10:2;

[0036] b. Preparation of PVA aqueous solution: wash, dry and weigh a 1000ml beaker to obtain mass m1, then add 760g deionized water into the beaker, add it in a 97°C constant temperature water bath, stir...

Embodiment 3

[0042] A method for preparing a water treatment membrane, through the preparation of a hollow fiber membrane, the preparation of a CMC solution and the pressing and molding steps, the preparation of a water treatment membrane is completed; the specific steps are as follows:

[0043] (1) Preparation of hollow fiber membrane:

[0044] a. Preparation of nano-silica sol: Mix tetraethoxysilane, titanium dioxide particles, absolute ethanol and deionized water into a beaker, then stir in a water bath at 70°C for 23 minutes, and then add dropwise ammonia water with a mass fraction of 15% 0.25g, prepared nano-silica sol after keeping it in a water bath at 50°C for 4 hours, the mixing ratio of tetraethoxysilane, titanium dioxide particles, absolute ethanol and deionized water is 4:1:9:1.5;

[0045] b. Preparation of PVA aqueous solution: wash, dry and weigh a 1000ml beaker to obtain mass m1, then add 760g deionized water into the beaker, add it in a 97°C constant temperature water bath,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com