Preparation method and catalytic application of Silicalite-1 single crystal-coated nanopalladium-loaded core-shell catalyst

A technology of core-shell catalysts and nano-palladium, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of unfavorable catalyst catalytic activity, poor catalyst monodispersity, and labor-intensive and material resources. Uniform particle distribution, solving the effect of poor monodispersity and high temperature aggregation resistance to metal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of Sil-1 nano-seeds

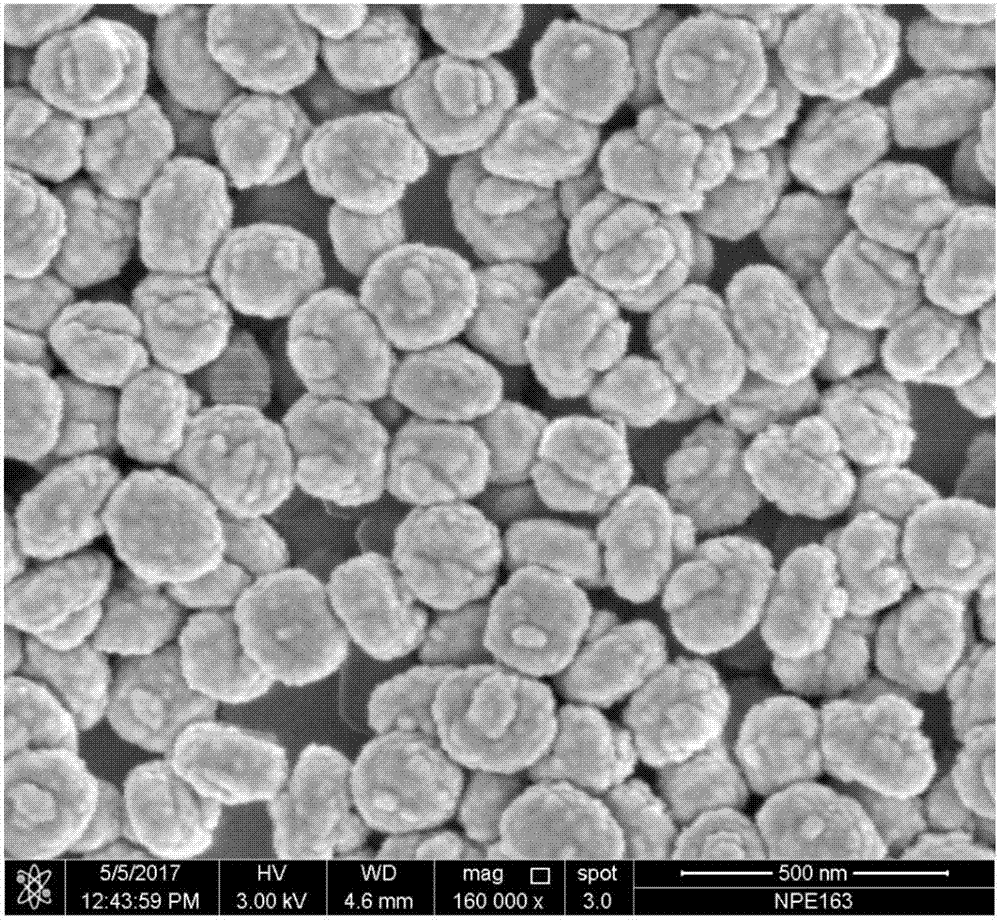

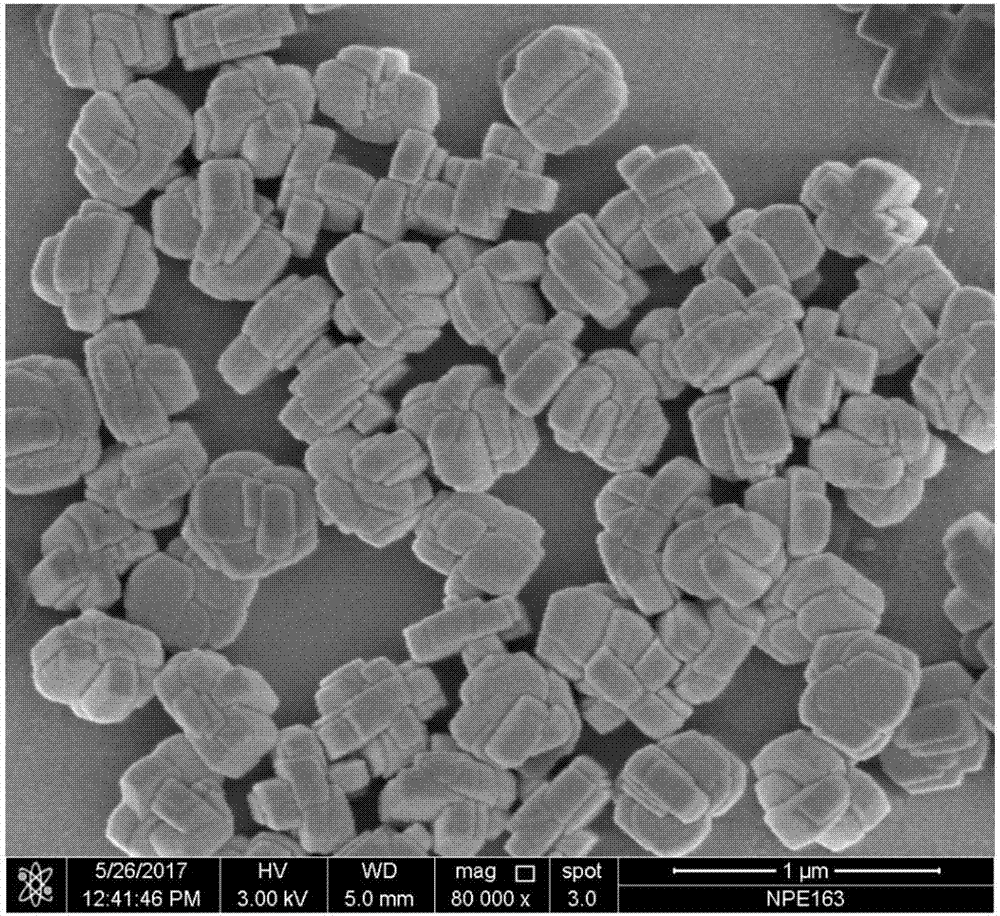

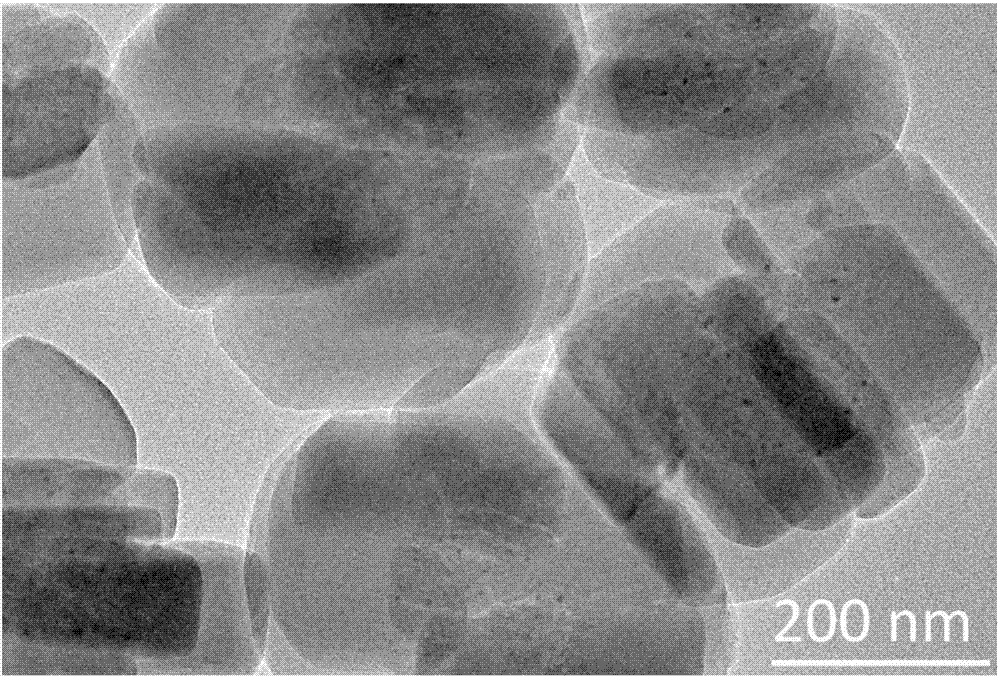

[0030] According to TPAOH:TEOS:H 2 The molar ratio of O=0.25:1:27, first measure 48.6 mL of deionized water, and add 23.85 mL of tetrapropylammonium hydroxide (TPAOH) under vigorous stirring. Keep stirring vigorously for 30min. Then, 22.7 mL of ethyl orthosilicate was added dropwise at a rate of 1 mL / min. After the dropwise addition was completed, it was stirred and aged for 24 h at room temperature. Put it into a synthesis kettle lined with polytetrafluoroethylene, and hydrothermally synthesize it in a static oven at 90°C for 18h. After the synthesis was completed, the product was taken out, washed by centrifugation and dispersed in ethanol to prepare an ethanol suspension with a seed crystal density of 0.018 g / mL. The morphology of the Sil-1 seed crystal is as follows figure 1 Shown, XRD as Figure 4 shown.

[0031] (2) Amino-modified Sil-1 nano-seeds and their interaction with Pd 2+ solid-load combination

[0032] Take 3...

Embodiment 2

[0040] (1) The preparation of Sil-1 nano-crystal seeds is the same as that in Example 1.

[0041] (2) Amino-modified Sil-1 nano-seeds and their interaction with Pd 2+ solid-load combination

[0042] Take 4 mL of the seed crystal suspension in step (1), add ethanol to 20 mL, and add 335 μL of 3-aminopropyltriethoxysilane with 2% mass of the above solution, heat treatment in a water bath at 60° C., and stir for 6 h. The sample was washed twice with deionized water and dispersed in 6 mL of deionized water to form a homogeneously dispersed amino-modified Sil-1 seed crystal suspension. Take 0.003gNa 2 PdCl 4 The solid powder was dissolved in 4 mL of deionized water, and the solution was added dropwise to the above amino-modified Sil-1 seed crystal suspension. After the dropwise addition, the mixture was stirred in a water bath at 30° C. for 2 h to obtain a Pd / Sil-1 supported catalyst.

[0043] (3) Synthesis of Pd@Sil-1 core-shell catalyst

[0044] According to TEOS:TPAOH:H 2...

Embodiment 3

[0047] (1) The preparation of Sil-1 nano-crystal seeds is the same as that in Example 1.

[0048] (2) Amino-modified Sil-1 nano-seeds and their interaction with Pd 2+ solid-load combination

[0049] Take 5 mL of the seed crystal suspension in step (1), add ethanol to 20 mL, and add 335 μL of 3-aminopropyltriethoxysilane with a mass of 2% of the above solution, heat treatment in a water bath at 60° C., and stir for 6 h. The sample was washed twice with deionized water and dispersed in 6 mL of deionized water to form a homogeneously dispersed amino-modified Sil-1 seed crystal suspension. Take 0.005gNa 2 PdCl 4 The solid powder was dissolved in 4 mL of deionized water, and the solution was added dropwise to the above amino-modified Sil-1 seed crystal suspension. After the dropwise addition, the mixture was stirred in a water bath at 30° C. for 2 h to obtain a Pd / Sil-1 supported catalyst.

[0050] (3) Synthesis of Pd@Sil-1 core-shell catalyst

[0051] According to TEOS:TPAOH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com