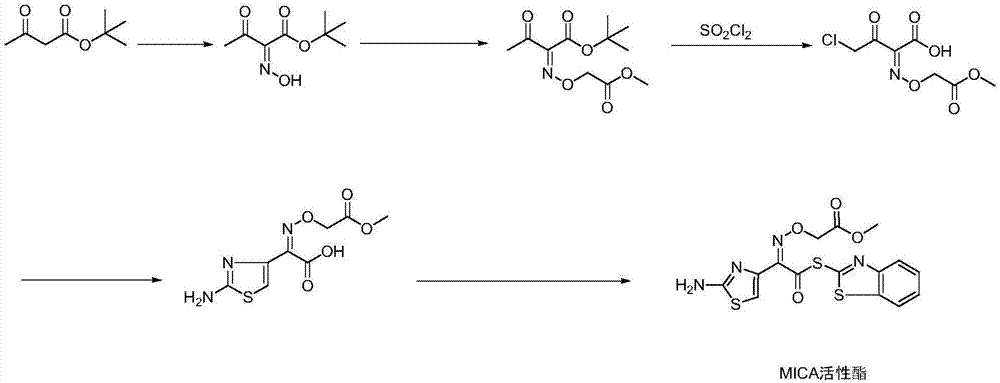

Environmental friendly production method of MICA active ester

A production method and active ester technology, applied in the direction of organic chemistry, can solve problems such as unresolved, high production cost, and large amount of waste water, and achieve the effects of reducing costs and waste water, saving costs, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0038] S1. Add 150kg of ethyl acetate, 100kg of tert-butyl acetoacetate and 50kg of glacial acetic acid into the reaction kettle in turn, continue to cool down to -10--5°C, start to add the solution of 48kg of sodium nitrite and 96kg of water dropwise. The process control temperature does not exceed 0°C, continue to stir for 8-12 hours after the dropwise addition, the reaction is complete, stop the reaction, let it stand for 1 hour, separate the lower organic layer, extract the water phase with 100kg ethyl acetate once more, and combine in The machine is directly used in the second step; the water phase is distilled to one-half volume, cooled to about 5°C, left to stand for 0.5 hours, discharged and centrifuged, dried to obtain 62kg of sodium acetate trihydrate, and the filtrate can be obtained by repeating the above operations to obtain trihydrate Sodium acetate 13kg, altogether obtains sodium acetate trihydrate 75kg and directly uses S4;

[0039] S2. Add 75 kg of methyl chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com