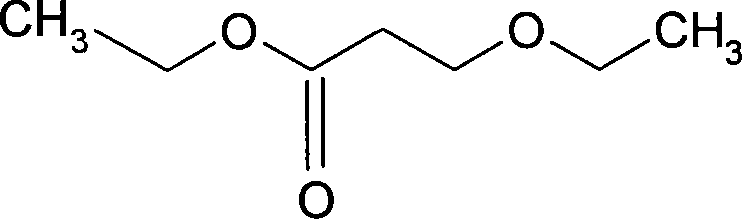

Preparation method of 3-ethoxyl ethyl propionate

A technology of ethyl ethoxy propionate and ethyl acrylate, applied in the field of preparation of ethyl 3-ethoxy propionate, can solve problems such as affecting production efficiency, increasing difficulty in processing, solvent recovery, etc., and improving production efficiency , The effect of reducing solvent recovery and consumption, and reducing by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

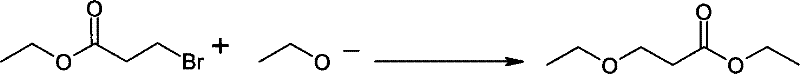

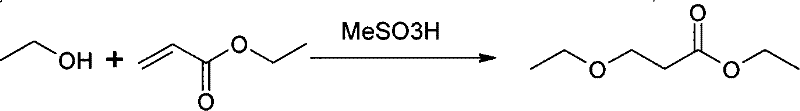

Method used

Image

Examples

Embodiment 1

[0030] (1) Synthesis of 3-ethoxy ethyl propionate

[0031] Add 1.6g of sodium metal and 160g of ethanol to a four-necked flask equipped with an electric stirring device, a thermometer, a constant pressure dropping funnel and a reflux condenser, and slowly add 290g of ethyl acrylate dropwise under strong stirring for 1 hour. In the flask, the reaction was continued for 2 hours at a reaction temperature of 45±2°C.

[0032] (2) Neutralizer

[0033] Slowly add 7g of 98% concentrated sulfuric acid into the flask under cooling and stirring, and control the temperature of the system to ≤20°C, and the material in the flask is in a state of suspension.

[0034] (3) Recovery of unreacted materials and refining of products

[0035] The above-mentioned suspension is added in the tower still of glass rectification tower, open vacuum and carry out underpressure distillation (20mmHg), and agitator is housed in this tower still. Raise the temperature and heat until reflux appears at the to...

Embodiment 2

[0041] Add 1.5g of sodium metal and 175g of ethanol to a four-necked flask equipped with an electric stirring device, a thermometer, a constant pressure dropping funnel and a reflux condenser, and slowly add 290g of ethyl acrylate dropwise for 1 hour under strong stirring. In described flask, continue to react with 2 hours, and reaction temperature is 45 ± 2 ℃, all the other catalysts are neutralized, the recovery of unreacted material, the refinement of product are all the same as (2), (3) in embodiment 1 , The finished product yield is 89%, and the content is greater than 99%.

Embodiment 3

[0043] Reclaim product front cut 46g among the embodiment 1, wherein ethanol accounts for 61%, ethyl acrylate accounts for 7%, and product 3-ethoxy ethyl propionate accounts for 32%; Metal sodium 0.5g is first added to the four-necked flask described in Example 1, and the ethyl acrylate recovered and 145g of added fresh ethyl acrylate are slowly added dropwise to the flask under vigorous stirring for 1 hour, and continue Reaction with 2 hours, reaction temperature is 45 ± 2 ℃, and all the other catalysts are neutralized, the recovery of unreacted material, the refinement of product are all the same as (2) and (3) in embodiment 1, product 3-ethoxypropane Acetate ethyl ester yield is 92%, and total yield is 96.3% [(total yield %=the newly added 3-ethoxy ethyl propionate in the reaction generation 3-ethoxy ethyl propionate / raw material ) moles × 100%].

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com