Method for synthesis of high-temperature-resistant carborane-containing polyimide resin

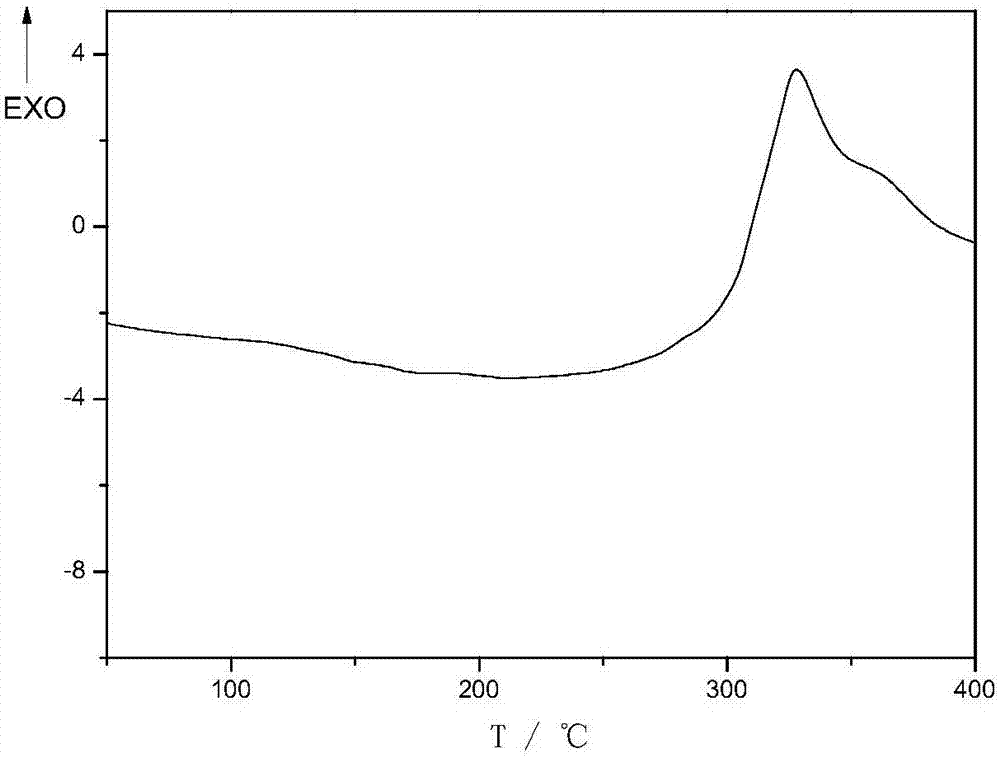

A technology of polyimide resin and synthesis method, which is applied in the field of resin synthesis, can solve problems such as inability to meet application requirements, and achieve the effects of improving oxidation stability, excellent heat resistance and oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A kind of synthetic method of high temperature resistant carborane-containing polyimide resin of the present invention comprises the following steps:

[0048] Chemical formula:

[0049]

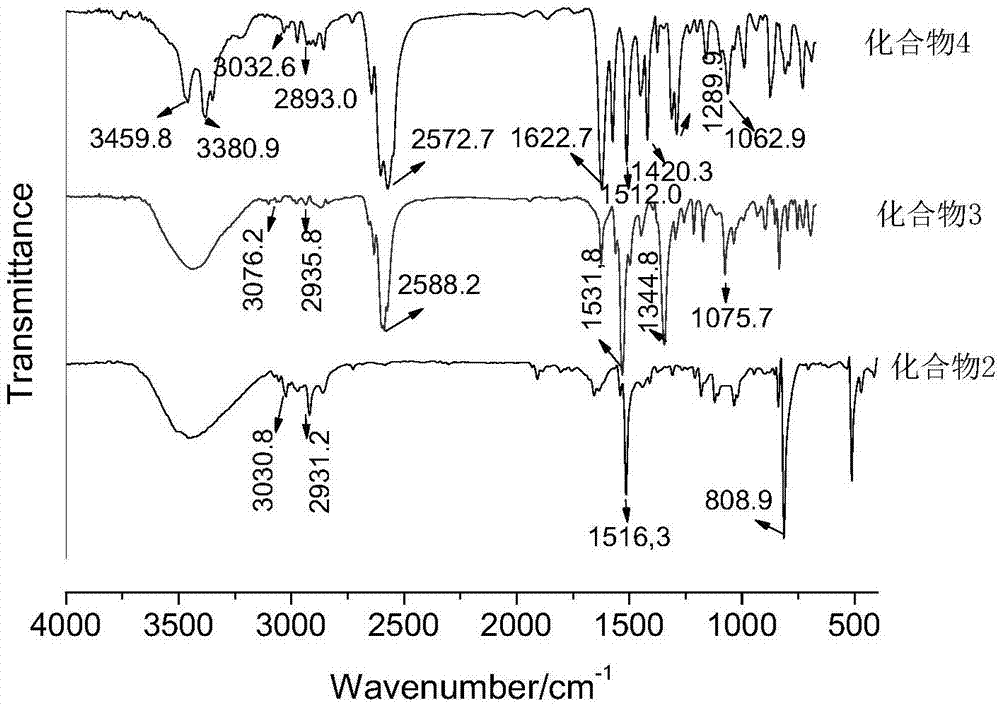

[0050] Among them, compound 1 is 4-ethynyltoluene, compound 2 is 4-carborane toluene, compound 3 is 2,6-dinitro-4-carborane toluene, compound 4 is 2,6-diamino-4 - carborane toluene.

[0051] (1) Synthesis of compound 2 from compound 1

[0052] In the three-necked flask a, add compound 1 of Ag and B of Bg in sequence 10 h 12 (CH 3 EN) 2 and C g toluene, compounds 1 and B 10 h 12(CH 3 EN) 2 It can be completely dissolved in toluene, where A:B=1:1.5~1:3, A:C=1:17~1:20, then react at 100~120°C for 20~24 hours, then stop heating to end the reaction.

[0053] Next, the toluene was distilled off under reduced pressure at 60-90°C, and then methanol was added for recrystallization, finally M g white crystal compound 2 was obtained, wherein A:M=1:1~1:1.5.

[0054] (2) Synthesis of ...

Embodiment 1

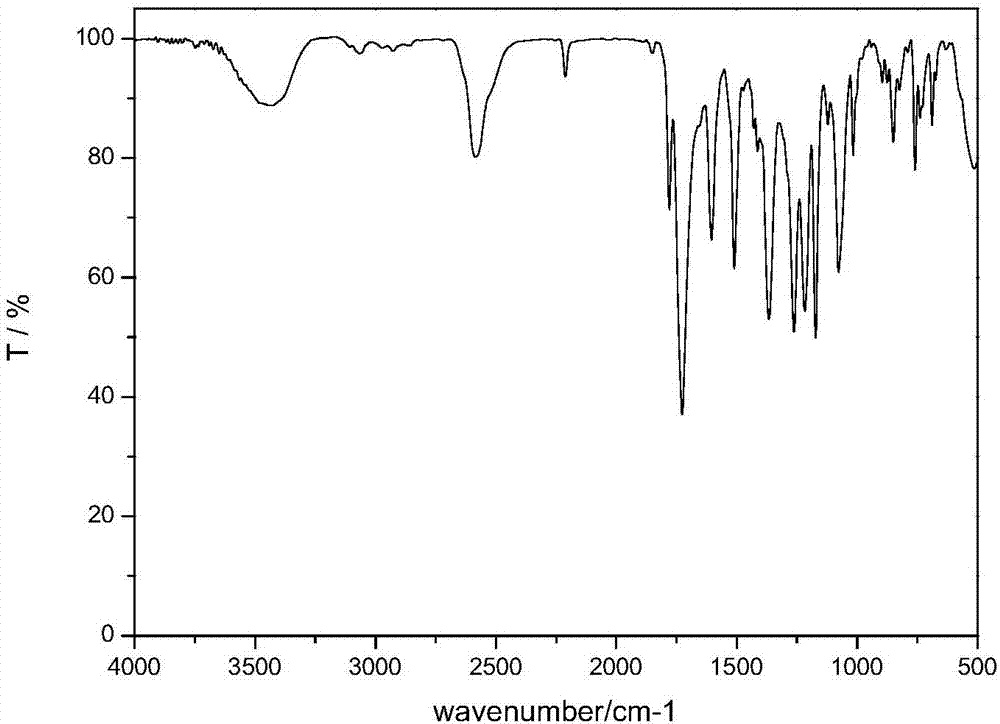

[0065] In a 250mL three-necked flask, add 5.2g of 4-ethynyltoluene, 14.8g of B 10 h 12 (CH 3 EN) 2 And 100g toluene, after reacting at 110°C for 20h, the reaction was terminated. Toluene was distilled off under reduced pressure at 70° C., and methanol was added for recrystallization to obtain 5.6 g of compound 2 as white crystals.

[0066] Put 5.6g of compound 2 in a 100mL three-neck flask, add 10g of dichloromethane, and stir evenly. Next, 2 g of fuming nitric acid and 20 g of concentrated sulfuric acid were added dropwise at a rate of 1 drop / second in an ice-water bath. After the dropwise addition, the reaction was continued for 3 h at room temperature and the reaction was terminated to obtain a mixture. The mixture was poured into ice water and separated with a separatory funnel to obtain a water phase solution and an oil phase solution, wherein the water phase solution was extracted with dichloromethane and combined with the oil phase solution, and then the solution wa...

Embodiment 2

[0071] In a 500mL three-necked flask, add 11g of 4-ethynyltoluene, 20g of B 10 h 12 (CH 3 EN) 2 And 200g toluene, after reacting at 110°C for 24h, the reaction was terminated. Toluene was distilled off under reduced pressure at 80°C, and methanol was added for recrystallization to obtain 12 g of compound 2 as white crystals.

[0072] Take 12g of compound 2 and place it in a 200mL three-necked flask, then add 20g of dichloromethane, and mechanically stir evenly. Next, 3 g of fuming nitric acid and 25 g of concentrated sulfuric acid were added dropwise at a rate of 2 drops / second in an ice-water bath. After the dropwise addition, the reaction was continued for 5 h at room temperature and the reaction was terminated to obtain a mixture. The mixture was poured into ice water and separated with a separatory funnel to obtain a water phase solution and an oil phase solution, wherein the water phase solution was extracted with dichloromethane and combined with the oil phase soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com