Ionized covalent organic frame material as well as preparation method and catalytic application of ionized covalent organic frame material

A covalent organic framework and ionization technology, applied in the field of material chemistry, can solve the problems of cumbersome catalyst recovery process, affecting catalyst utilization efficiency, poor conversion rate, etc., and achieve excellent catalytic effect, novel technology, and stable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

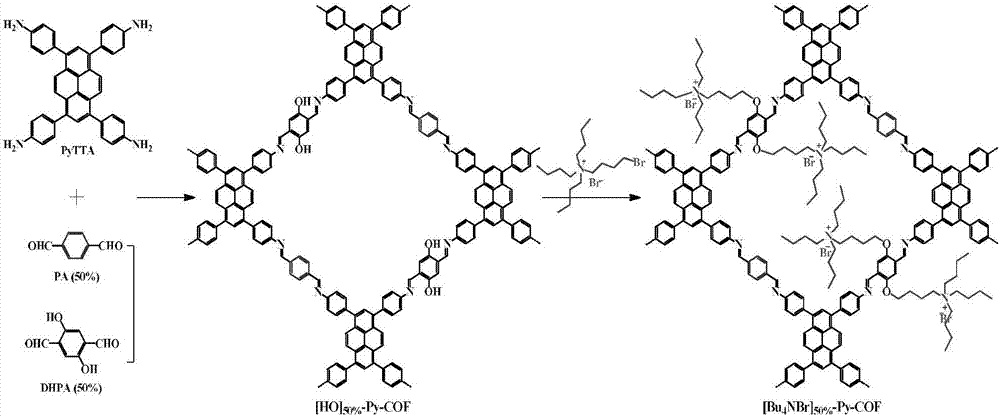

[0016] The synthesis of embodiment 1.HO-Py-COF material

[0017] 0.02mmol of 4,4′,4″,4″′-(pyrene-1,3,6,8-tetrayl)tetraaniline (hereinafter referred to as PyTTA), 0.02mmol of 2,5-dihydroxyterephthalaldehyde (hereinafter referred to as DHPA) and 0.02mmol of 1,4-phthalaldehyde (hereinafter referred to as PA) was added to the ampoule, and then 1.0mL of o-dichlorobenzene and 0.1mL of 6M acetic acid solution were ultrasonically mixed, and the ampoule was placed in liquid nitrogen to freeze and pumped. Vacuum, repeat this operation 3 times to ensure the vacuum state in the ampoule, seal the mouth of the bottle with flame, and place it in a container at 120°C for 72 hours. After the reaction, the product was washed three times with tetrahydrofuran and acetone, and the product after removing the solvent was dried in 0.01Mpa vacuum at 120°C for 12 hours, and finally a brown powder was obtained as the product, with a yield of 90% and a BET specific surface area of 2153m 2 g -1 , the...

Embodiment 2-5

[0018] The synthesis of embodiment 2-5.HO-Py-COF material

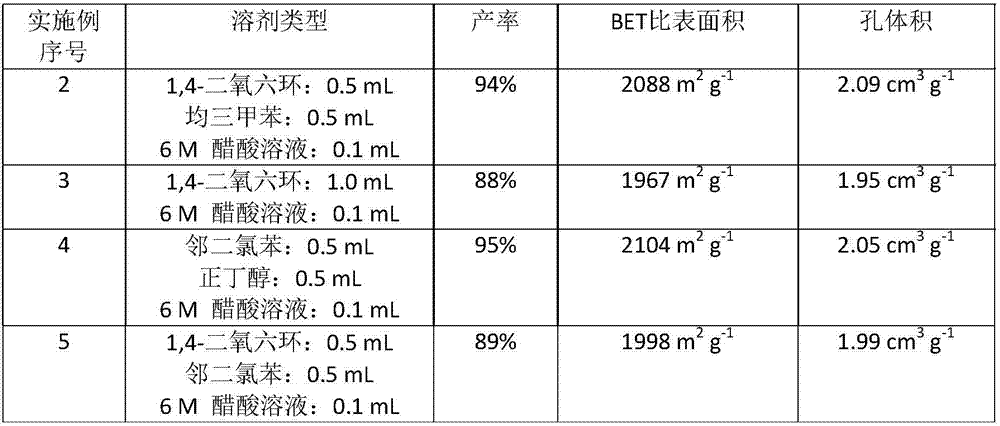

[0019] Synthetic method as described in embodiment 1, its difference is:

[0020]

Embodiment 6

[0021] Example 6. Bu 4 Synthesis of NBr-Py-COF Material

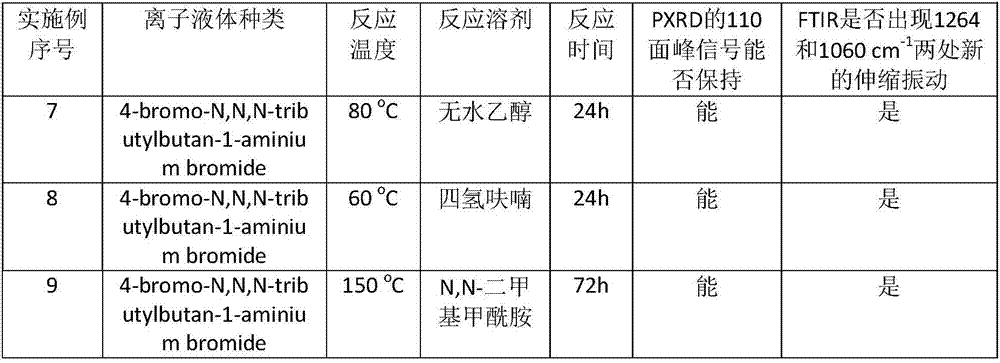

[0022] 30mg of HO-Py-COF, 30mg of 4-bromo-N, N, N-tributylbutan-1-aminium bromide and 21mg of K 2 CO 3 They were weighed into 50mL round bottom flasks respectively, then 5mL of dry N,N-dimethylformamide was added, and heated and stirred at 150°C for 24h. After the reaction is completed, filter, wash the solid with ethanol and acetone three times, and then dry it in a vacuum oven at 0.1-1Mpa at 100°C for 12 hours to finally obtain red and black Bu 4 NBr-Py-COF material, tested by PXRD, the 110 surface peak signal of the material remains, confirming that the crystal form of the COF material after ionization is maintained; by FTIR measurement, the COFs material after ionization compared with the material before ionization, appears 1264 and two new C-O-C and C-N stretching vibrations at 1060cm-1, confirming the successful ionization of the COF material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com