Preparation method of environment-friendly non-volatile mineral wool fiber pipe insulation material

A technology of mineral wool fiber and pipe insulation, which is applied in the field of thermal insulation materials and can solve problems such as endangering the environment and human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

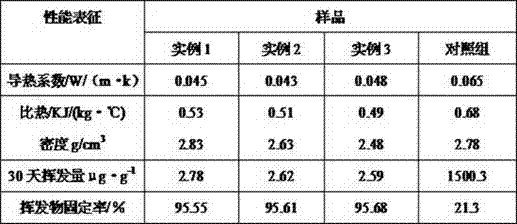

Examples

example 1

[0022] According to the mass ratio of 1:10, polystyrene was added to dichloroethane, and the mixture was obtained after standing at room temperature for 1 hour. According to the mass ratio of 1:1:24, aluminum chloride and sodium bicarbonate were added to the mixture After stirring and mixing for 25 minutes, adjust the pH to 2.5 with mixed acid, heat in a water bath at 55°C for 6 hours, let it stand and cool to room temperature, adjust the pH to 8.5 with 0.1mol / L sodium hydroxide solution, and stir and mix for 10 minutes. Filter the filter cake, wash with deionized water until the washing liquid is neutral, and vacuum dry for 3 hours to obtain modified resin particles; by weight, weigh 25 parts of phenolic resin, 15 parts of modified porous resin particles, 2 parts of zinc oxide, 1 part of paraffin, 0.1 part of antioxidant 168, 0.01 part of antioxidant 1010, 3 parts of dibutyl phthalate and 1 part of triethanolamine are placed in the internal mixer, and the temperature of the he...

example 2

[0024] According to the mass ratio of 1:10, polystyrene was added to dichloroethane, and the mixture was obtained after standing at room temperature for 1 hour. According to the mass ratio of 1:1:24, aluminum chloride and sodium bicarbonate were added to the mixture After stirring and mixing for 27 minutes, adjust the pH to 2.5 with mixed acid, heat in a water bath at 57°C for 7 hours, let it stand and cool to room temperature, adjust the pH to 8.5 with 0.1mol / L sodium hydroxide solution, and stir and mix for 12 minutes. Filter the filter cake, wash with deionized water until the washing liquid is neutral, and vacuum-dry for 4 hours to obtain modified resin particles; in parts by weight, weigh 27 parts of phenolic resin, 17 parts of modified porous resin particles, 3 parts of zinc oxide, 2 parts of paraffin, 0.2 part of antioxidant 168, 0.02 part of antioxidant 1010, 4 parts of dibutyl phthalate and 2 parts of triethanolamine are placed in the internal mixer, and the temperatur...

example 3

[0026]According to the mass ratio of 1:10, polystyrene was added to dichloroethane, and the mixture was obtained after standing at room temperature for 2 hours. According to the mass ratio of 1:1:24, aluminum chloride and sodium bicarbonate were added to the mixture After stirring and mixing for 30 minutes, adjust the pH to 2.5 with mixed acid, heat in a water bath at 60°C for 8 hours, let it stand and cool to room temperature, adjust the pH to 8.5 with 0.1mol / L sodium hydroxide solution, and stir and mix for 15 minutes. Filter to obtain the filter cake, wash with deionized water until the washing liquid is neutral, and vacuum-dry for 5 hours to obtain modified resin particles; in parts by weight, weigh 30 parts of phenolic resin, 20 parts of modified porous resin particles, 3 parts of zinc oxide, 2 parts of paraffin, 0.2 part of antioxidant 168, 0.02 part of antioxidant 1010, 5 parts of dibutyl phthalate and 2 parts of triethanolamine are placed in the internal mixer, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com