Method for preparing manno-oligosaccharide from palm kernel meal by microwave-assisted low alkali

A technology of mannooligosaccharides and palm kernel meal, which is applied in the field of functional oligosaccharides, can solve the problems of less than 1% extraction rate of mannooligosaccharides, high cost, and long industrialization distance, etc., so as to be beneficial to environmental protection and reduce The effect of dosage and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

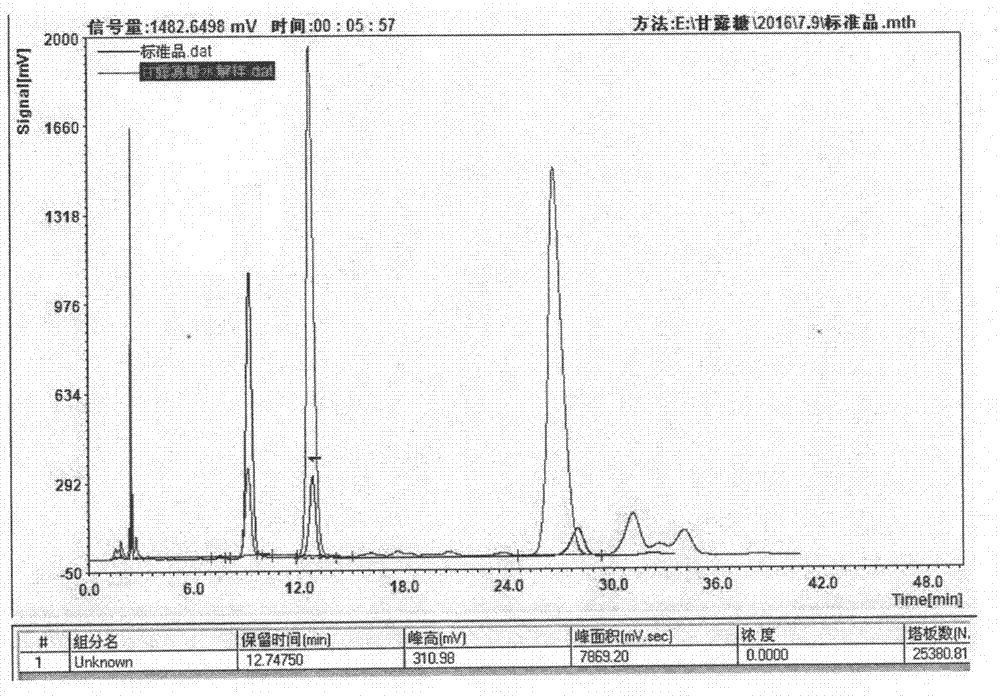

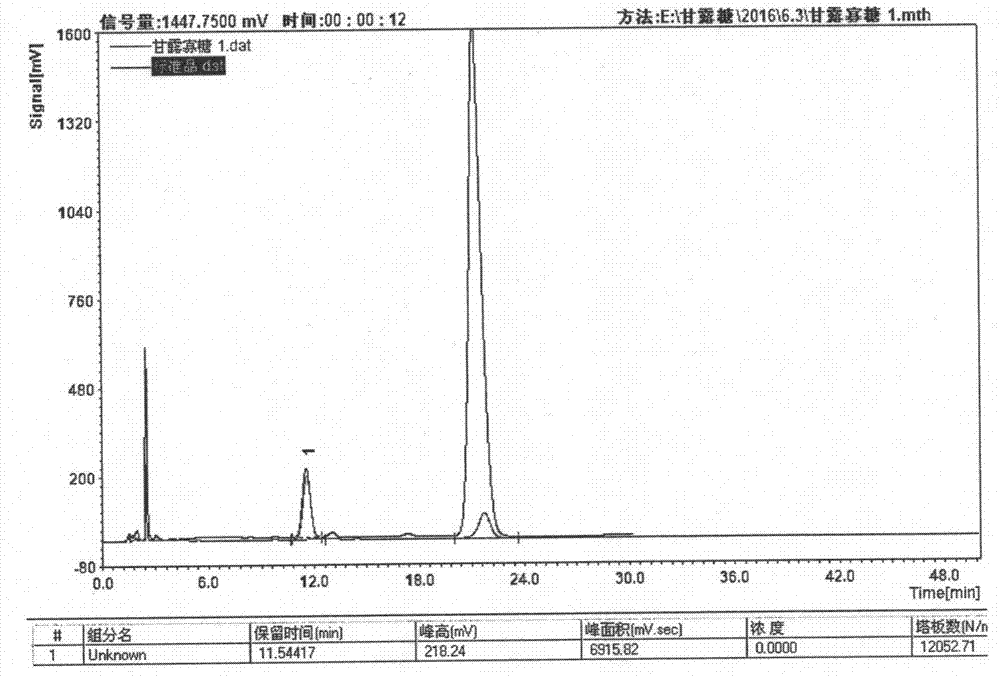

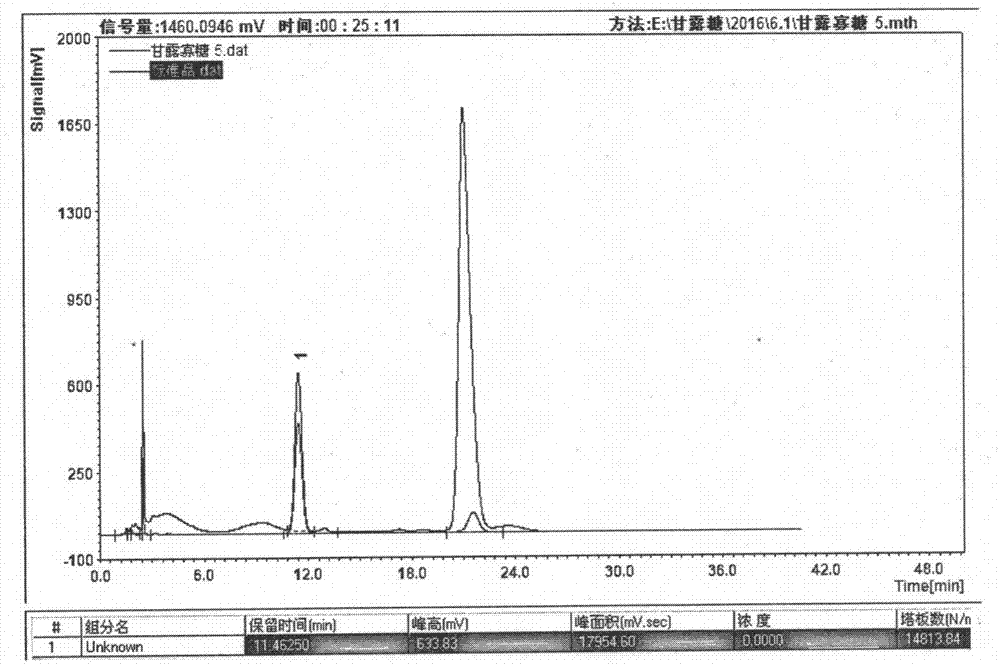

Image

Examples

Embodiment 1

[0027] A microwave-assisted low-alkali method for preparing mannooligosaccharides from palm kernel dregs:

[0028] Step 1): palm kernel meal pretreatment: crushing the palm kernel meal to a fineness of 50-60, 80-100, 200, 400 meshes and sieving respectively;

[0029] Step 2): Mix the pulverized palm kernel meal according to palm kernel meal: water=1:5, add water and stir evenly, then microwave-assisted extraction, the frequency of microwave is 2450mHz, adjust the pH value to 10 with lye, and process for more than 10 minutes ;

[0030] Step 3): After hydraulically filtering or centrifuging the mixture obtained in step 2), take the supernatant, adjust its pH value to 7, enzymatically hydrolyze with mannanase for 7-12 hours, and then concentrate in vacuo;

[0031] Step 4): The concentrated solution obtained in step 3) is centrifuged after alcohol precipitation, and the obtained precipitate is freeze-dried to obtain the crude product of mannooligosaccharides. The alcohol used for...

Embodiment 2

[0036] A microwave-assisted low-alkali method for preparing mannooligosaccharides from palm kernel dregs:

[0037] Step 1): palm kernel meal pretreatment: crushing the palm kernel meal to a fineness of 200 mesh and sieving;

[0038] Step 2): Mix the pulverized palm kernel meal according to palm kernel meal: water = 1:5, add water and stir evenly, then microwave-assisted extraction, the frequency of microwave is 2450mHz, and use saturated sodium hydroxide solution to adjust the pH value to 8, 9, 10, 11, 12, for more than 10 minutes;

[0039] Step 3): After hydraulically filtering or centrifuging the mixture obtained in step 2), take the supernatant, adjust its pH value to 7, use mannanase to enzymatically hydrolyze for 10 hours, and then concentrate in vacuo;

[0040] Step 4): The concentrated solution obtained in step 3) is subjected to alcohol precipitation and centrifuged, and the obtained precipitate is freeze-dried to obtain the crude mannooligosaccharide. The alcohol use...

Embodiment 3

[0043] A microwave-assisted low-alkali method for preparing mannooligosaccharides from palm kernel dregs:

[0044] Step 1): palm kernel meal pretreatment: crushing the palm kernel meal to a fineness of 200 mesh and sieving;

[0045] Step 2): After the pulverized palm kernel meal is mixed with water according to palm kernel meal: water=1:5, microwave-assisted extraction, the frequency of microwave is 2500mHz, and the pH value is adjusted to 10 respectively by using saturated sodium hydroxide solution. Treat 6min, 8min, 10min, 12min, 14min respectively;

[0046]Step 3): After hydraulically filtering or centrifuging the mixture obtained in step 2), take the supernatant, adjust its pH value to 7, enzymatically hydrolyze with mannanase for 8 hours, and then concentrate in vacuo;

[0047] Step 4): The concentrated solution obtained in step 3) is subjected to alcohol precipitation and centrifuged, and the obtained precipitate is freeze-dried to obtain the crude mannooligosaccharide....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com