Efficient plant dead steam recycling device

A waste steam recovery and factory technology, applied in the field of petrochemical industry, can solve the problems of low recycling rate, increased consumption of circulating water, heat recovery of waste steam, etc., and achieve the effect of saving energy, eliminating heat pollution, and good process continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

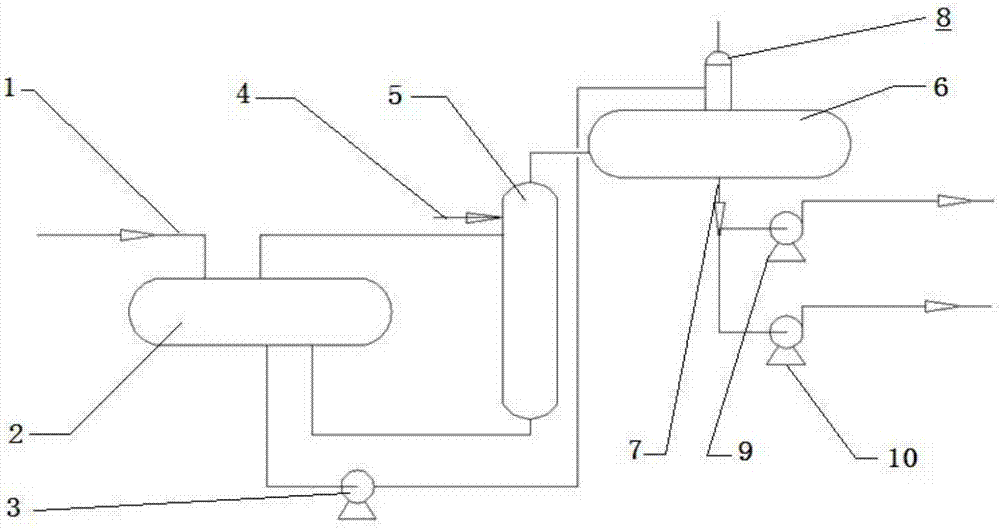

[0010] Below in conjunction with accompanying drawing, the present invention will be further described:

[0011] as the picture shows:

[0012] Open the condensed water inlet 1, inject the condensed water into the condensed water tank 2, lead the exhausted steam in the condensed water tank 2 from the upper end of the condensed water tank 2 to the mixing water tank 5, open the desalted water inlet 4, and inject 45°C cold desalted water , the 45°C cold desalted water is mixed with the exhaust steam of the factory for heat exchange, most of the exhaust steam is condensed and recovered, and the rest is led to the deaerator 6 for deoxygenation steam, and the desalinated water heated to about 85°C is sent from the mixing tank 5 to the deaerator 6 for degassing and oxygen removal in the deaerator 6, the condensed water drawn from the lower port of the condensed water tank 2 is led to the deaerator 6 through the condensed water pump 3, and the gas in the deaerator 6 Degassing and deo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com