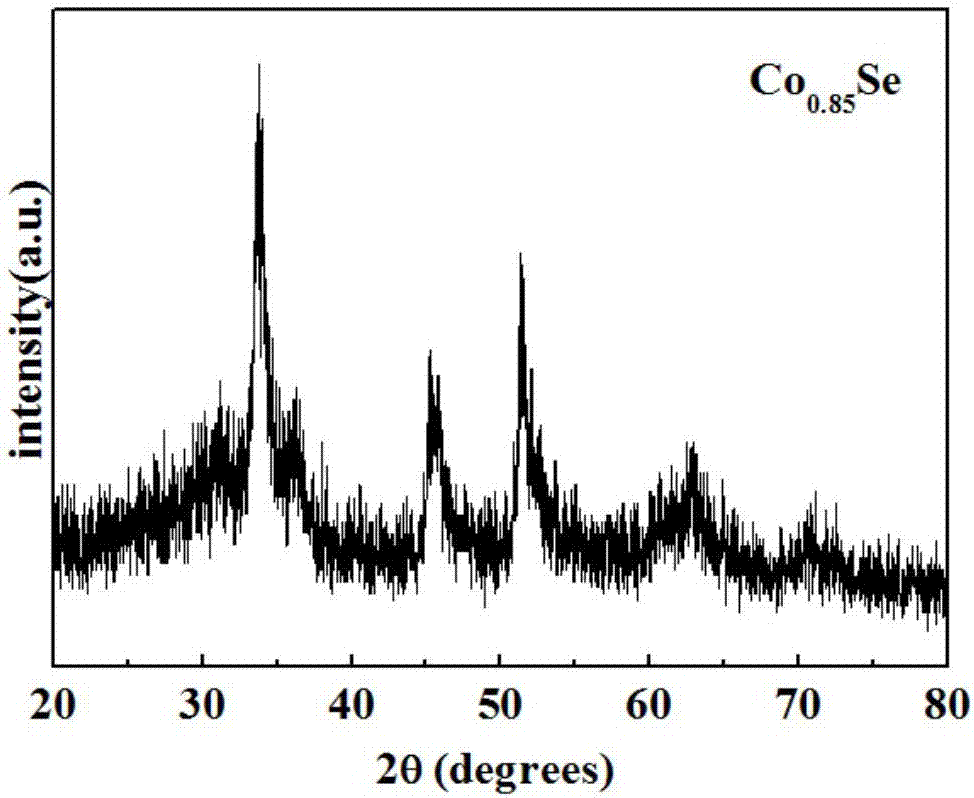

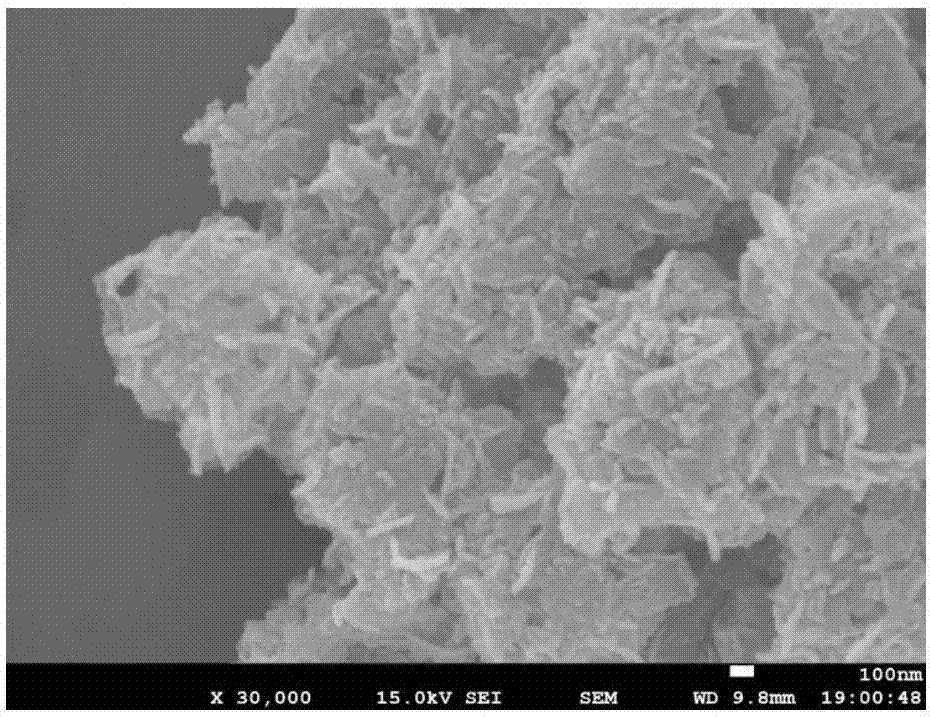

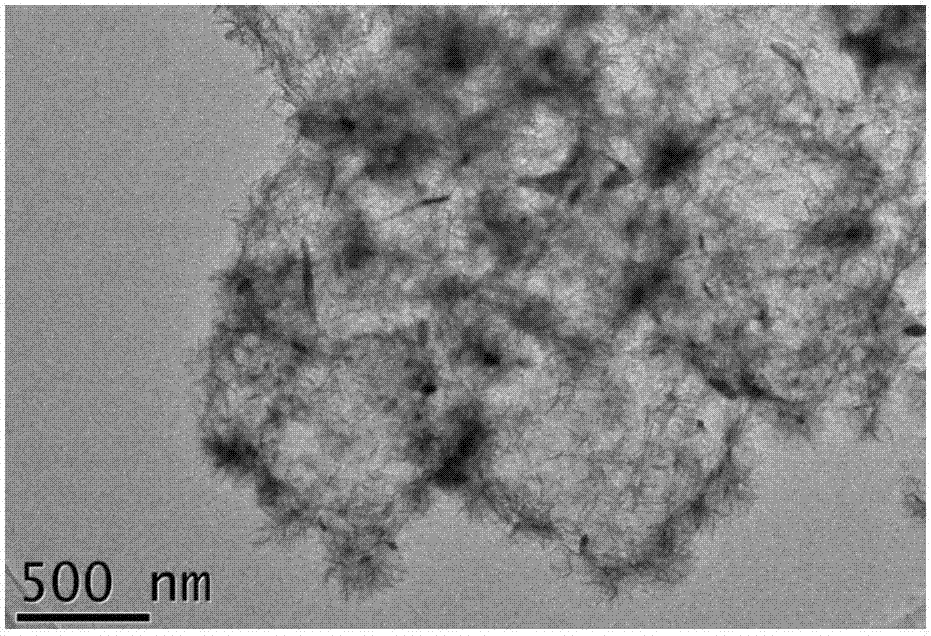

Preparation method of hollow Co0.85Se nanometer polyhedral particles

A polyhedral, nanotechnology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of good powder dispersion, short production cycle and novel method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh Co(NO 3 ) 2 ·6H 2 0.3 g of O powder, 0.3 g of dimethylimidazole powder and 25 ml of methanol form a mixed solution respectively. Stir the prepared two solutions separately for 5 minutes, then add the mixed solution of dimethylimidazole and methanol dropwise into the mixed solution of cobalt nitrate hexahydrate and methanol for reaction. Stirring, keeping at room temperature for 24h, centrifuging and washing to obtain polyhedral precursor MOFs of Co. Take 40mg of Co precursor and 12ml of deionized water to make a mixed solution, then gradually add 20mg of selenous acid, 20ml of hydrazine hydrate, stir for 1min, transfer the mixed solution to the reactor for hydrothermal treatment, and keep the hydrothermal temperature at 160 ℃, the hydrothermal time is kept at 24h, and the powder after the reaction is centrifuged to clean, and finally the hollow Co 0.85 Se nanopolyhedral particles.

Embodiment 2

[0022] Weigh Co(NO 3 ) 2 ·6H 2 O powder 0.5g, dimethylimidazole powder 0.5g and 40ml methanol respectively form a mixed solution. Stir the prepared two solutions separately for 5 minutes, then add the mixed solution of dimethylimidazole and methanol dropwise into the mixed solution of cobalt nitrate hexahydrate and methanol for reaction. Stirring, keeping at room temperature for 24h, centrifuging and washing to obtain polyhedral precursor MOFs of Co. Take 30mg of Co precursor and 15ml of deionized water to make a mixed solution, then gradually add 20mg of selenous acid and 20ml of hydrazine hydrate, stir for 1min, transfer the mixed solution to the reactor for hydrothermal treatment, and keep the hydrothermal temperature at 160 ℃, the hydrothermal time is kept at 24h, and the powder after the reaction is centrifuged to clean, and finally the hollow Co 0.85 Se nanopolyhedral particles.

Embodiment 3

[0024] Weigh Co(NO 3 ) 2 ·6H 2 0.3 g of O powder, 0.3 g of dimethylimidazole powder and 25 ml of methanol form a mixed solution respectively. Stir the prepared two solutions separately for 5 minutes, then add the mixed solution of dimethylimidazole and methanol dropwise into the mixed solution of cobalt nitrate hexahydrate and methanol for reaction. Stirring, keeping at room temperature for 24h, centrifuging and washing to obtain polyhedral precursor MOFs of Co. Take 40mg of Co precursor and 15ml of deionized water to make a mixed solution, then gradually add 10mg of selenous acid and 20ml of hydrazine hydrate, stir for 1min, then transfer the mixed solution to the reactor for hydrothermal treatment, and keep the hydrothermal temperature at 180 ℃, the hydrothermal time is kept at 18h, and the powder after the reaction is centrifuged to clean, and finally the hollow Co 0.85 Se nanopolyhedral particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com