Antibacterial and anti-fouling modified adhesive and preparation method thereof

An adhesive and modifier technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problem of poor bonding strength, unsatisfactory cold resistance, and antibacterial and anti-fouling performance that cannot meet actual production requirements. needs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

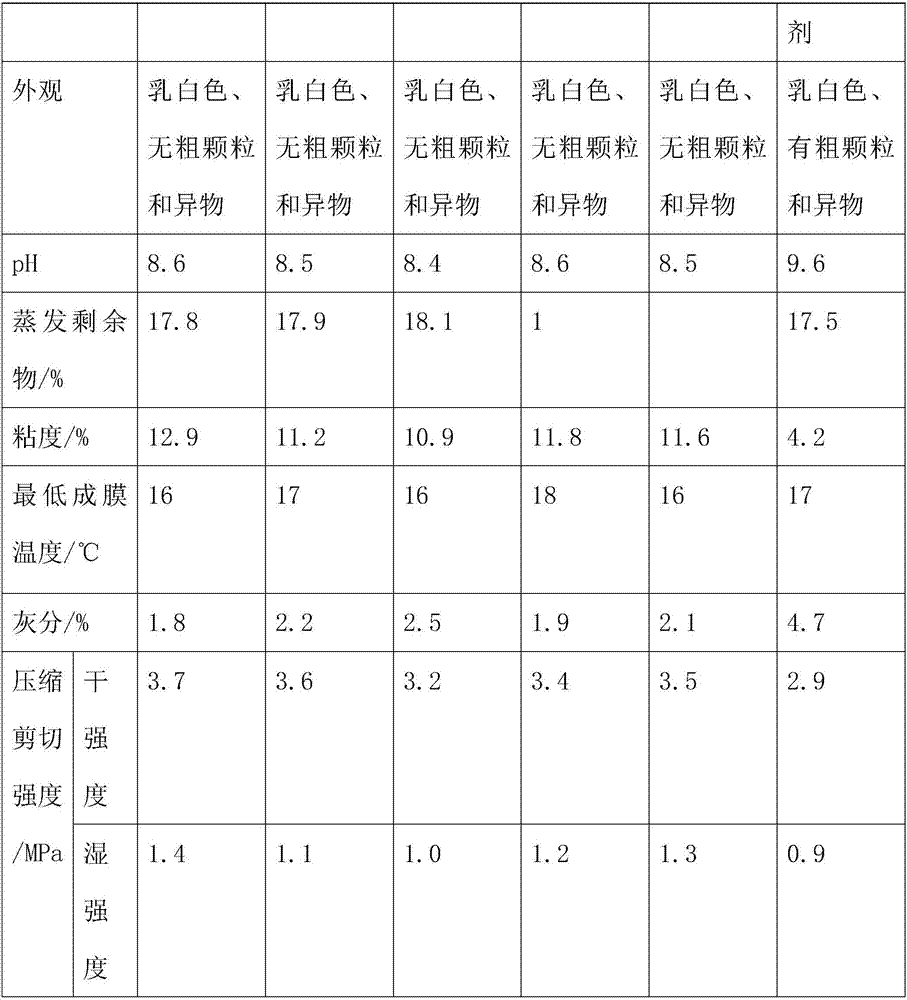

Embodiment 1

[0016] The antibacterial and antifouling modified adhesive proposed by the present invention includes raw materials by weight: 50 parts of polyurethane, 6 parts of methyl methacrylate, 3.5 parts of butyl acrylate, 2.5 parts of methacrylic acid, and 2 parts of benzoyl peroxide. parts, 10 parts of potassium persulfate, 6 parts of polyvinyl alcohol, 3.5 parts of diacetone acrylamide, 3 parts of adipic hydrazide, 4 parts of dibutyl phthalate, 3 parts of tributyl citrate, 3 parts of tartaric acid, 4.5 parts of sodium bicarbonate, 3.5 parts of antibacterial modifier, 2.5 parts of stain resistance enhancer, and 15 parts of deionized water.

[0017] The antibacterial modifier was prepared according to the following process: 4.5 parts by weight of 3,4-and-dihydroxybenzaldehyde, 3.5 parts of chitosan, 6.5 parts of distilled water, 4 parts of acetic acid and 3 parts of methanol were mixed uniformly, and left at room temperature for 4 hours. , then add 4 parts of sodium borohydride and mi...

Embodiment 2

[0021] The antibacterial and antifouling modified adhesive proposed by the present invention comprises, in parts by weight, raw materials: 40 parts of polyurethane, 9 parts of methyl methacrylate, 2 parts of butyl acrylate, 4 parts of methacrylic acid, and 1 part of benzoyl peroxide. parts, 15 parts of potassium persulfate, 3 parts of polyvinyl alcohol, 5 parts of diacetone acrylamide, 1 part of adipic hydrazide, 5 parts of dibutyl phthalate, 2 parts of tributyl citrate, 5 parts of tartaric acid, 3 parts of sodium bicarbonate, 5 parts of antibacterial modifier, 1 part of stain resistance enhancer, 20 parts of deionized water.

[0022] The antibacterial modifier was prepared according to the following process: 3 parts by weight of 3,4-and-dihydroxybenzaldehyde, 5 parts of chitosan, 4 parts of distilled water, 5 parts of acetic acid and 2 parts of methanol were mixed uniformly, and left at room temperature for 5 hours. , then add 3 parts of sodium borohydride and mix evenly, sti...

Embodiment 3

[0026] The antibacterial and antifouling modified adhesive proposed by the present invention comprises, in parts by weight, raw materials: 60 parts of polyurethane, 3 parts of methyl methacrylate, 5 parts of butyl acrylate, 1 part of methacrylic acid, and 3 parts of benzoyl peroxide. parts, 5 parts of potassium persulfate, 9 parts of polyvinyl alcohol, 2 parts of diacetone acrylamide, 5 parts of adipic hydrazide, 3 parts of dibutyl phthalate, 4 parts of tributyl citrate, 1 part of tartaric acid, 6 parts of sodium bicarbonate, 2 parts of antibacterial modifier, 4 parts of stain resistance enhancer, 10 parts of deionized water.

[0027] The antibacterial modifier is prepared according to the following process: Mix 6 parts by weight of 3,4-and-dihydroxybenzaldehyde, 2 parts of chitosan, 9 parts of distilled water, 3 parts of acetic acid and 4 parts of methanol, and let stand at room temperature for 3 hours , then add 5 parts of sodium borohydride and mix evenly, stir at 650r / min ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com