Antibacterial fouling-resistant linen artificial cotton elastic fabric

A kind of artificial cotton and linen technology, applied in the field of fabrics, can solve problems such as inability to meet, poor antibacterial and stain resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

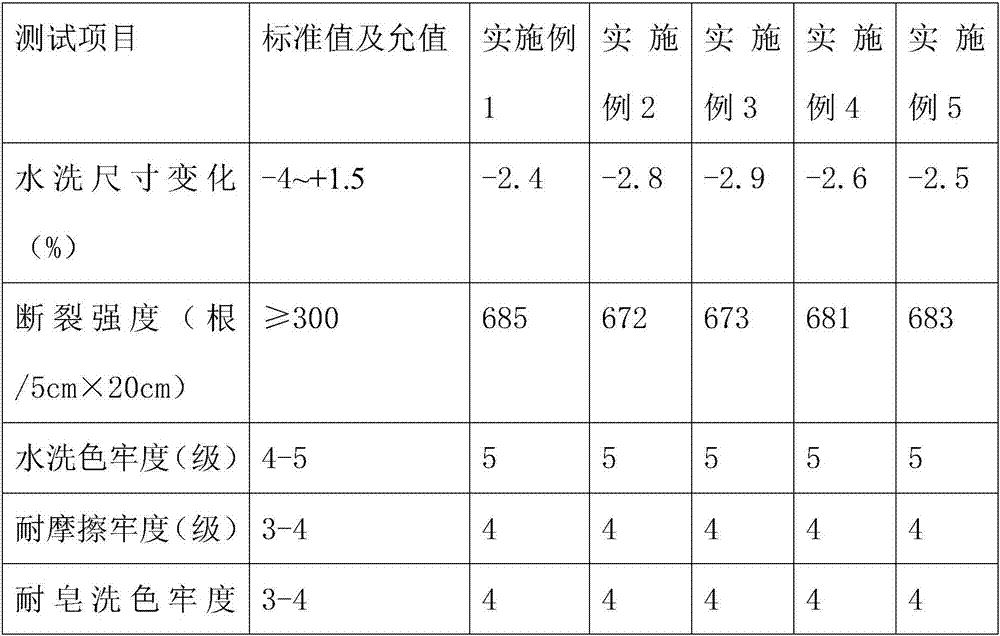

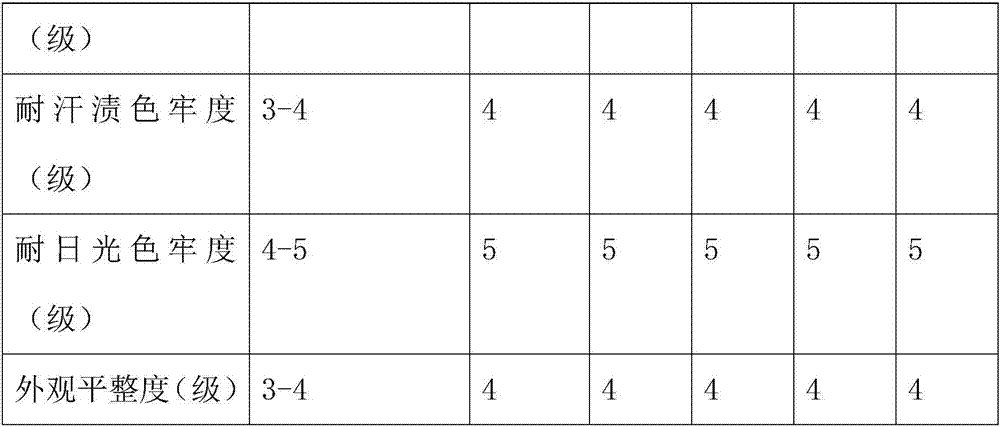

Examples

Embodiment 1

[0016] A kind of antibacterial and stain-resistant flax rayon elastic fabric proposed by the present invention, its raw material comprises by weight: 30 parts of polyester fiber, 4.5 parts of bamboo charcoal fiber, 3.5 parts of flax fiber, 2.5 parts of bamboo fiber, 4 parts of corn fiber, acetic acid 4 parts of fiber, 3 parts of chitin fiber, 4.5 parts of seaweed fiber, 3.5 parts of nano-silver powder, 2 parts of nano-zinc oxide, 3.5 parts of trimethylolpropane, 4.5 parts of aluminum stearate, 2.5 parts of polyvinyl alcohol, 4 parts of sodium benzoate 4 parts, 4 parts of activated carbon powder, 6 parts of modified antibacterial copolymers, 4 parts of antibacterial enhancement additives, and 3 parts of antifouling additives.

[0017] The modified antibacterial copolymer is prepared according to the following process: 2 parts of N-(4-hydroxy-3-methoxy-benzyl) acrylamide and 3.5 parts of N,N-dimethylacetamide are mixed uniformly by weight, Stir at 750r / min for 30min, then raise ...

Embodiment 2

[0021] A kind of antibacterial and stain-resistant flax rayon elastic fabric proposed by the present invention, its raw material comprises by weight: 20 parts of polyester fiber, 6 parts of bamboo charcoal fiber, 2 parts of flax fiber, 4 parts of bamboo fiber, 3 parts of corn fiber, acetic acid 6 parts of fiber, 1 part of chitin fiber, 6 parts of seaweed fiber, 2 parts of nano-silver powder, 3 parts of nano-zinc oxide, 2 parts of trimethylolpropane, 6 parts of aluminum stearate, 1 part of polyvinyl alcohol, 5 parts of sodium benzoate 2 parts, 2 parts of activated carbon powder, 9 parts of modified antibacterial copolymers, 2 parts of antibacterial enhancement additives, and 5 parts of antifouling additives.

[0022]The modified antibacterial copolymer is prepared according to the following process: 1 part of N-(4-hydroxy-3-methoxy-benzyl) acrylamide and 5 parts of N,N-dimethylacetamide are mixed uniformly by weight, Stir at 650r / min for 40min, then raise the temperature to 75°...

Embodiment 3

[0026] A kind of antibacterial and stain-resistant flax rayon elastic fabric proposed by the present invention, its raw material comprises by weight: 40 parts of polyester fiber, 3 parts of bamboo charcoal fiber, 5 parts of flax fiber, 1 part of bamboo fiber, 5 parts of corn fiber, acetic acid 2 parts of fiber, 5 parts of chitin fiber, 3 parts of seaweed fiber, 5 parts of nano-silver powder, 1 part of nano-zinc oxide, 5 parts of trimethylolpropane, 3 parts of aluminum stearate, 4 parts of polyvinyl alcohol, 3 parts of sodium benzoate 6 parts, 6 parts of activated carbon powder, 3 parts of modified antibacterial copolymers, 6 parts of antibacterial enhancement additives, and 1 part of antifouling additives.

[0027] The modified antibacterial copolymer is prepared according to the following process: 3 parts of N-(4-hydroxy-3-methoxy-benzyl) acrylamide and 2 parts of N,N-dimethylacetamide are mixed uniformly by weight, Stir at 850r / min for 20min, then raise the temperature to 85...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com