Lithium-thionyl chloride battery and production thereof

A thionyl chloride battery and battery cell technology, applied in the field of lithium batteries, can solve the problems of uneven dispersion of discharge products and small discharge current, and achieve the effects of avoiding overheating, increasing tolerance, and increasing safety and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

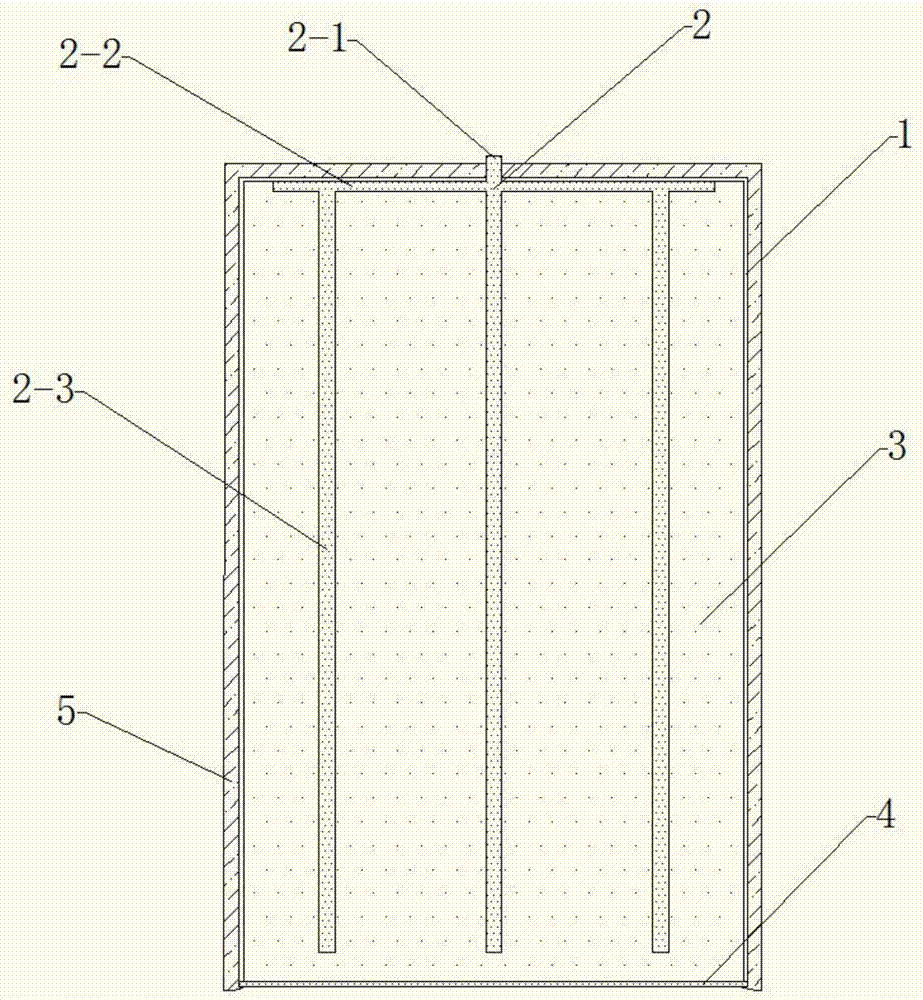

[0031] A lithium-thionyl chloride battery is characterized in that it includes a casing 5 and a core body, the core body includes a coating 1, a current collector 2, a filler 3 and an anode sheet 4, and the coating 1 is closed at one end and one end An open hollow column filled with the filler 3, the current collector 2 is a metal sheet 2-2 with a metal protrusion 2-1 on one side, and the metal protrusion 2-1 passes through the package The membrane 1 and the casing 5 form the positive pole of the lithium-thionyl chloride battery, the anode sheet 4 is airtightly connected to the opening end of the envelope 1, and the casing 5 is airtightly connected to the edge of the anode sheet 4, The exposed part of the anode sheet 4 forms the negative electrode of the lithium-thionyl chloride battery, and the other side of the current collector 2 is provided with several current collecting columns 2-3, and the composition of the current collecting columns 2-3 is nickel, the number There are...

Embodiment 2

[0035] A lithium-thionyl chloride battery is characterized in that it includes a casing 5 and a core body, the core body includes a coating 1, a current collector 2, a filler 3 and an anode sheet 4, and the coating 1 is closed at one end and one end An open hollow column filled with the filler 3, the current collector 2 is a metal sheet 2-2 with a metal protrusion 2-1 on one side, and the metal protrusion 2-1 passes through the package The membrane 1 and the casing 5 form the positive pole of the lithium-thionyl chloride battery, the anode sheet 4 is airtightly connected to the opening end of the envelope 1, and the casing 5 is airtightly connected to the edge of the anode sheet 4, The exposed part of the anode piece 4 forms the negative electrode of the lithium-thionyl chloride battery, and the other side of the current collector 2 is provided with a number of current collecting columns 2-3, and the composition of the current collecting columns 2-3 is titanium, the number The...

Embodiment 3

[0039] A lithium-thionyl chloride battery is characterized in that: it includes a casing 5 and a core body, the core body includes a coating 1, a current collector 2, a filler 3 and an anode sheet 4, and the coating 1 is closed at one end and one end An open hollow column filled with the filler 3, the current collector 2 is a metal sheet 2-2 with a metal protrusion 2-1 on one side, and the metal protrusion 2-1 passes through the package The membrane 1 and the casing 5 form the positive pole of the lithium-thionyl chloride battery, the anode sheet 4 is airtightly connected to the opening end of the envelope 1, and the casing 5 is airtightly connected to the edge of the anode sheet 4, The exposed part of the anode piece 4 forms the negative electrode of the lithium-thionyl chloride battery, and the other side of the current collector 2 is provided with a number of current collecting columns 2-3, and the composition of the current collecting columns 2-3 is platinum. There are 5 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com