Low temperature lithium ion battery

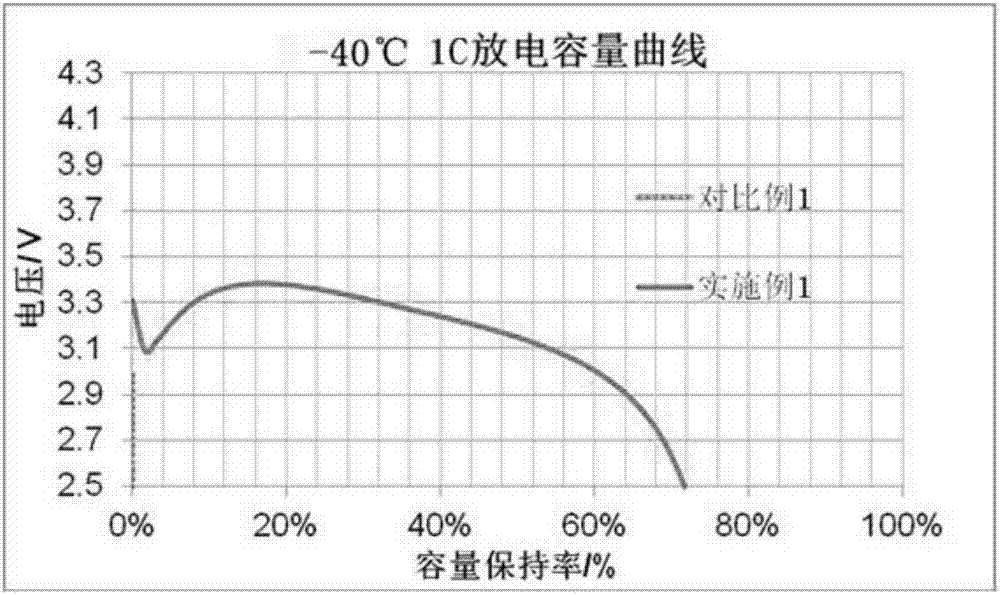

A lithium-ion battery, low-temperature technology, applied in the field of lithium-ion batteries, can solve the problems of low discharge rate, long heating time, and application field limitations, and achieve the effects of increasing initial discharge voltage, improving kinetic performance, and overcoming poor discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

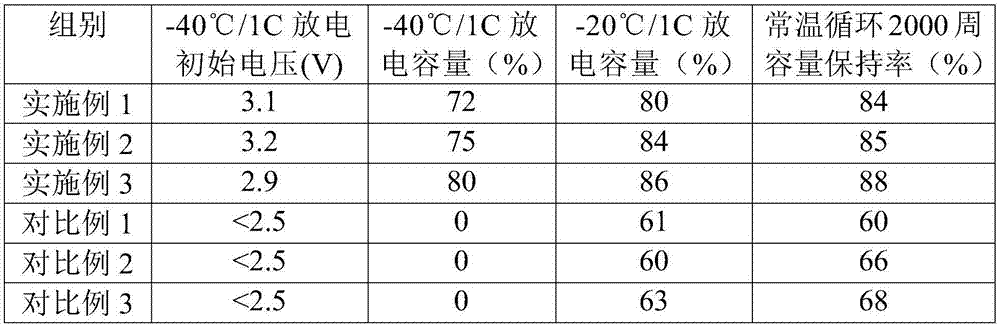

Embodiment 1

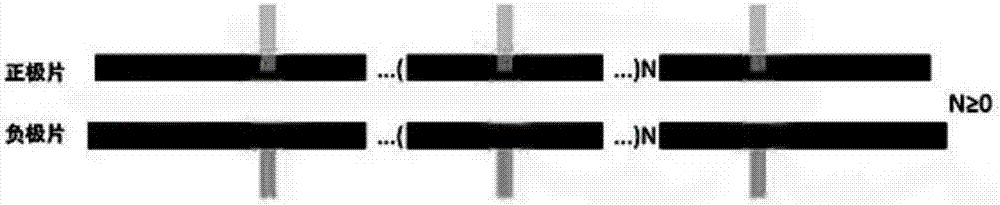

[0025] A cylindrical ternary power ultra-low temperature lithium-ion battery of the present invention comprises a cylindrical casing, a winding core accommodated in the casing, an electrolyte and a battery cap, and the winding core is sequentially stacked by a negative electrode sheet, a separator and a positive electrode sheet. It is formed by winding, and the electrolyte penetrates into the winding core. There are at least two positive tabs between the battery cap and the positive tab. One end of the positive tab is connected to the battery cap, and the other end of the positive tab is connected to the positive tab. There are at least two negative tabs, one end of the negative tab is connected to the negative plate, and the other end of the negative tab is connected to the bottom of the housing; wherein, the composition of the positive plate, separator, negative plate, electrolyte and cell structure is as follows:

[0026] Positive electrode sheet: The positive electrode acti...

Embodiment 2

[0032] Different from Example 1, the composition of positive electrode sheet, separator, negative electrode sheet and electrolyte is as follows:

[0033] Positive electrode sheet: The positive electrode active material is lithium nickel cobalt aluminate doped with lithium manganese oxide, and the surface of lithium nickel cobalt aluminate is coated with Li 14 Zn(GeO 4 ) 4 ; In the positive electrode active material, lithium nickel cobalt aluminate: lithium manganese oxide: Li 14 Zn(GeO 4 ) 4 The weight percentage is 80%: 15%: 5.0%, and the median particle size D50 of the ternary material is 3-11 μm; the median particle size D50 of lithium manganate is 3-20 μm; the conductive agent is carbon nanotube, sticky The binding agent is polyvinylidene fluoride; wherein, the positive electrode active material: conductive agent: the weight percentage of binder is 96%: 2%: 2%; the thickness of the positive electrode sheet is 80 μm, and the compacted density of the positive electrode s...

Embodiment 3

[0039] Different from Example 1, the composition of positive electrode sheet, separator, negative electrode sheet and electrolyte is as follows:

[0040] Positive electrode sheet: The positive electrode active material is lithium nickel cobalt aluminate doped with lithium manganese oxide, and the surface of lithium nickel cobalt aluminate is coated with Li 3.3 La 0.56 TiO 3 ; In the positive electrode active material, lithium nickel cobalt aluminate: lithium manganese oxide: Li 3.3 La 0.56 TiO 3 The weight percentage is 75%: 20%: 5.0%, and the median particle size D50 of the ternary material is 3-11 μm; the median particle size D50 of lithium manganate is 3-20 μm; the conductive agent is carbon nanotube, sticky The binding agent is polyvinylidene fluoride; wherein, the positive electrode active material: conductive agent: the weight percentage of binder is 97%: 1.5%: 1.5%; the thickness of the positive electrode sheet is 130 μm, and the compacted density of the positive el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com