Preparation method of multilayer-embedded microcapsules

A microcapsule and single-layer technology, which is applied in the field of preparation of multilayer embedded microcapsules, can solve the problems of poor continuity and uniformity, long reaction time, etc., to improve continuity and uniformity, save cost and energy consumption, The effect of increasing the sustained release time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a method for preparing two-layer embedded microcapsules, comprising the following steps:

[0048] (1) material preparation

[0049] Take 0.05 g of water-soluble solid drug (cepiryl chloramine), 1 g of protective agent (olive oil), and add 1 g of emulsifier (equal amounts of tween80 and span80) as the total core material.

[0050] Take 1g of chitosan, 0.5g of modified starch, add 1ml of acetic acid (solvent) and 50ml of distilled water, stir and dissolve at 50°C, and use it as wall material A.

[0051] Take 1g of sodium lauryl sulfate, 3g of sodium tripolyphosphate, and 0.3g of sodium alginate and dissolve them in 100ml of distilled water at the same time as coagulation bath A.

[0052] Dissolve 0.1g of sodium alginate in 25ml of distilled water as wall material B.

[0053] Dissolve 0.5g of calcium chloride in 25ml of distilled water as coagulation bath B.

[0054] (2) Single layer wrapping

[0055] Wall material A is mixed with the total core ...

Embodiment 2

[0060] This embodiment provides a method for preparing two-layer embedded microcapsules, comprising the following steps:

[0061] (1) material preparation

[0062] Take 0.05 g of water-soluble solid drug (cepiryl chloride), 1 g of protective agent (soybean oil), and add 1 g of emulsifier (equal amounts of tween80 and span80) as the total core material.

[0063] Take 1g of chitosan, 0.5g of modified starch, add 1ml of acetic acid and 50ml of distilled water, stir and dissolve at 50°C, and use it as wall material A. Take 1g of sodium lauryl sulfate, 3g of sodium tripolyphosphate, and 0.3g of sodium alginate and dissolve them in 100ml of distilled water at the same time as coagulation bath A.

[0064] Take 0.5g chitosan and dissolve in 50ml distilled water as wall material B.

[0065] Coagulation bath A was reused as coagulation bath B.

[0066] (2) Single layer wrapping

[0067] After the wall material A is mixed with the total core material and homogenized by high-speed she...

Embodiment 3

[0073] This embodiment provides a method for preparing two-layer embedded microcapsules, comprising the following steps:

[0074] (1) material preparation

[0075] Total core material, wall material A, wall material B and coagulation bath B are consistent with embodiment 1.

[0076] Take 0.6g of sodium lauryl sulfate, 1.8g of sodium tripolyphosphate, and 0.3g of sodium alginate and dissolve them in 100ml of distilled water at the same time as the coagulation bath A.

[0077] (2) The steps of single-layer wrapping and double-layer wrapping are the same as in Example 1.

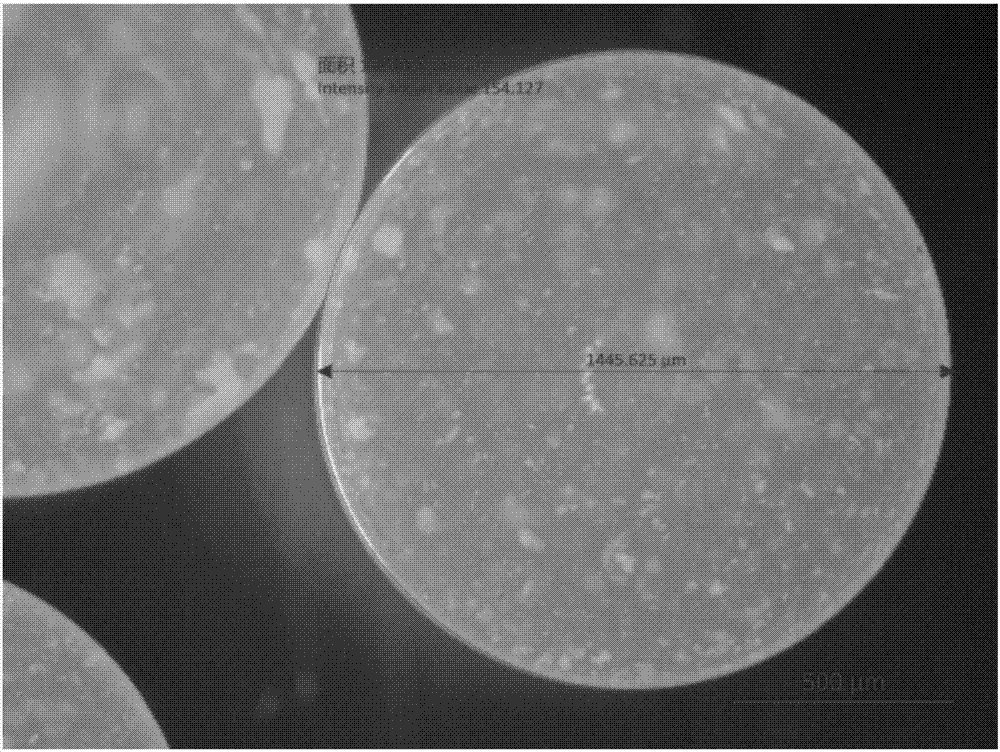

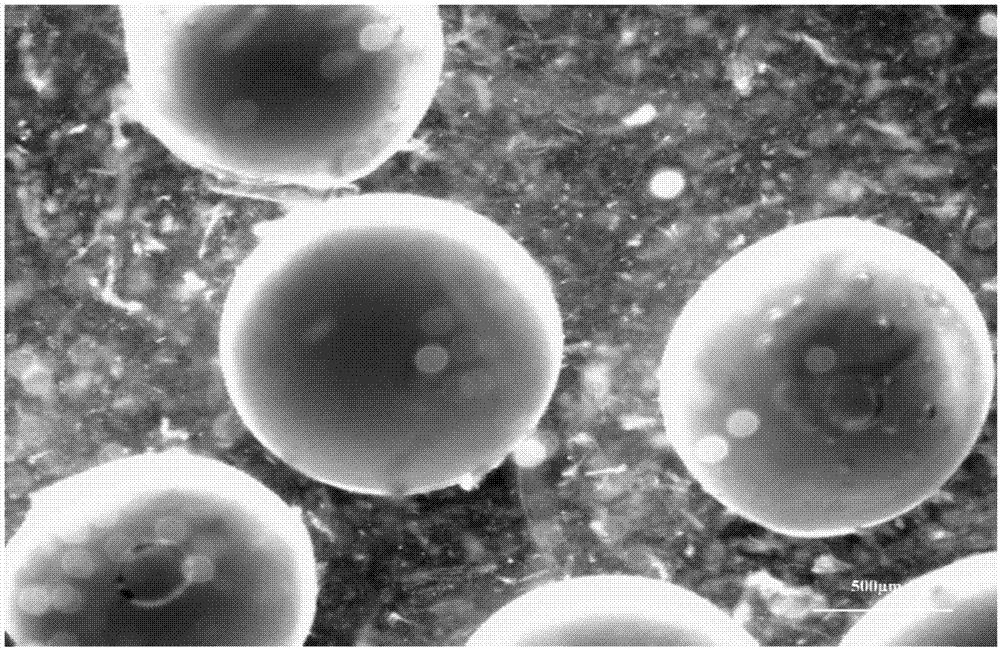

[0078] When the emulsion is squeezed through the orifice in the single-layer encapsulation step, the size of the microcapsules is controlled by selecting the size of the orifice used. The particle size distribution of the secondary embedding microcapsules prepared in this example is uniform, with an average particle size of 500 μm.

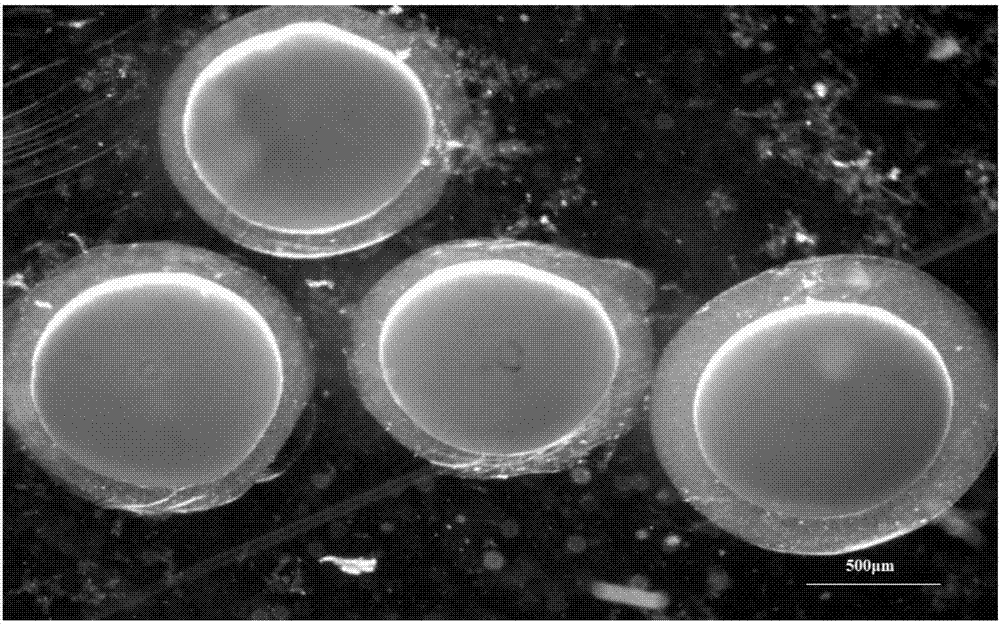

[0079] Observing the wrapping condition of the secondary embedding microcaps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com