Greenhouse crop growth inspection robot

A technology for inspection robots and crop growth, applied in manipulators, manufacturing tools, etc., can solve problems such as intelligent inspection robots for real-time monitoring of the greenhouse micro-environment that have not yet been developed, and achieve the effect of ensuring quality and uniformity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

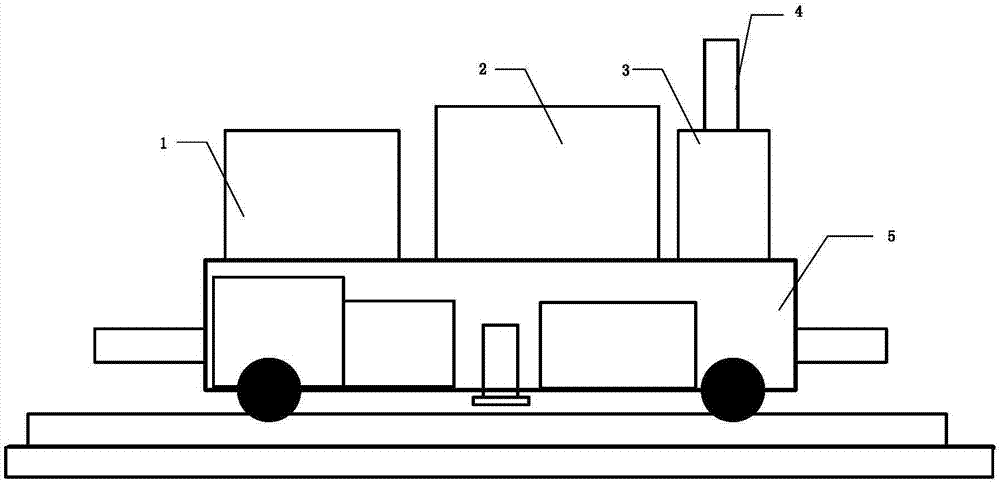

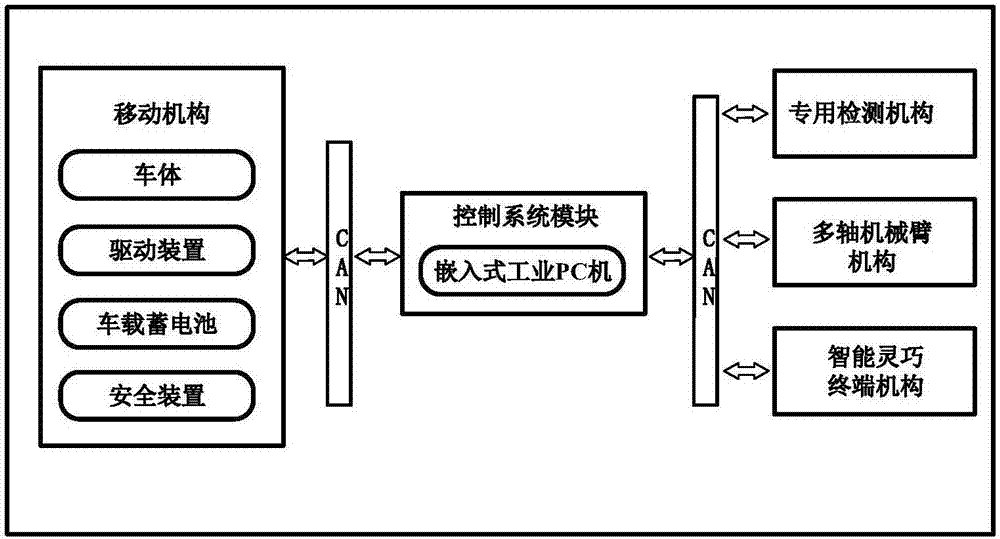

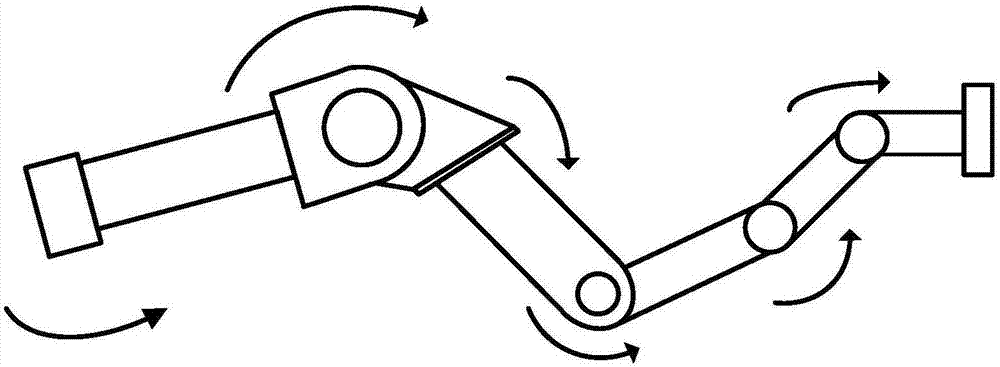

[0023] In this example, see Figure 1 ~ Figure 3 , a greenhouse crop growth inspection robot, mainly including a special detection mechanism 1, a control system module 2, a multi-axis mechanical arm mechanism 3, an intelligent smart terminal mechanism 4 and a mobile mechanism 5; the special detection mechanism 1 is used to detect soil pH and Soil temperature and humidity information; the multi-axis mechanical arm mechanism 3 is used to grasp and position the leaves of the target plant; the smart smart terminal mechanism 4 is used to detect the growth microenvironment information of the target plant, and the smart smart terminal mechanism 4 is installed At the free end of the multi-axis mechanical arm mechanism 3; the mobile mechanism 5 is located below the inspection robot, as a transport carrier for the inspection robot, and is used to realize the inspection robot walking on the space track. The multi-axis mechanical arm mechanism 3, the control system Both the module 2 and t...

Embodiment 2

[0030] This embodiment is basically the same as Embodiment 1, especially in that:

[0031] In this embodiment, the moving mechanism 5 is provided with an infrared light non-contact anti-collision sensor, a contact anti-collision sensor and a bumper. In this embodiment, in order to ensure the safety of the mobile robot itself and the safety of on-site personnel and various equipment during operation, the mobile robot in this embodiment adopts multi-level hardware and software security measures, and the mobile robot is equipped with infrared light non-contact anti-corrosion Collision sensors and contact anti-collision sensors and bumpers. The mobile robot is equipped with eye-catching signal lights and sound alarm devices, and has the function of uploading the fault status of the mobile robot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com