Photocatalysis-biology combined sewage treatment method

A technology of sewage treatment and photocatalysis, applied in biological water/sewage treatment, special compound water treatment, light water/sewage treatment, etc., can solve secondary pollution and other problems, achieve enhanced effect, reduce cost, and avoid secondary pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

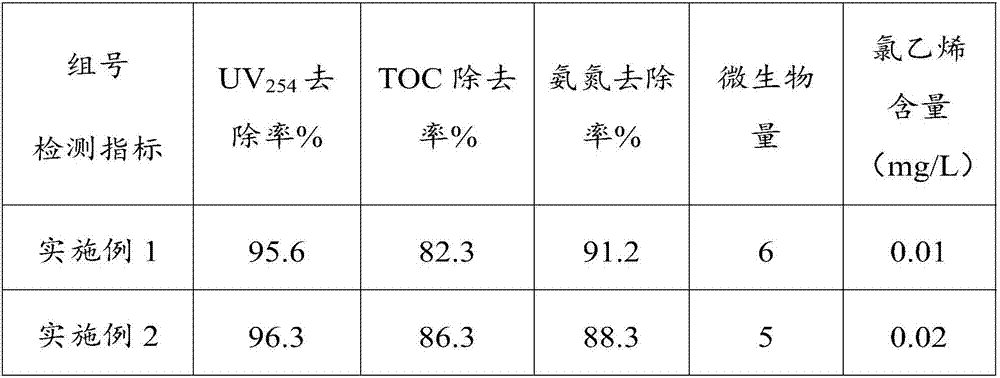

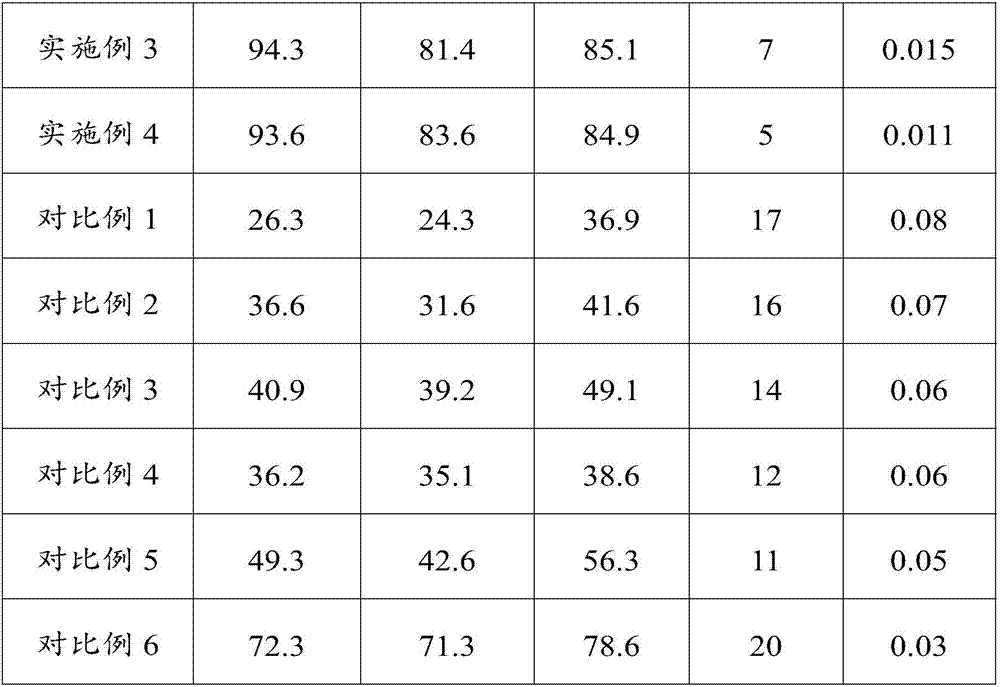

Examples

preparation example Construction

[0016] The preparation method of the above-mentioned aerobic microbial reactor includes preparing the aerobic microbial material, which includes activating the aerobic microorganisms, mixing the activated aerobic microorganisms with fillers to obtain a mixture, and then putting the carrier into the mixture for soaking. In detail, the above-mentioned filler can include graphite powder and sodium alginate with a weight ratio of 1-2:1, and the carrier can be a porous microbial carrier; the above-mentioned soaking can be carried out in the following manner: the carrier is soaked in the mixture of filler and aerobic microorganism , and then turn on the ultrasonic vibration, the vibration frequency can be 100-200Hz, and the time can be 20-30min. After soaking, take out the carrier and dry it. Sodium alginate has the functions of thickening and stabilizing. Adding sodium alginate to the filler can, on the one hand, stably fill the microbes in the pores of the carrier, so that the amou...

Embodiment 1

[0029] Prepare the aerobic microbial material in the aerobic microbial reactor: mix graphite powder and sodium alginate with a weight ratio of 1:1, and then add activated aerobic microorganisms to obtain a mixture; soak the carrier in the mixture, and Under the condition that the vibration frequency is 100Hz, vibrate for 30min.

[0030] Prepare the anaerobic microbial material in the anaerobic microbial reactor: mix graphite powder and sodium alginate with a weight ratio of 1:1, and then add activated anaerobic microorganisms to obtain a mixture; soak the carrier in the mixture, and Under the condition that the vibration frequency is 100Hz, vibrate for 30min.

[0031] After coarse filtration, the sewage is passed into the aerobic microbial reactor for primary biological treatment. The flow rate of the sewage flowing through the aerobic microbial reactor is 2m / h, and the temperature of the aerobic microbial reactor can be controlled at 28°C. After the primary biological treatm...

Embodiment 2

[0035] Prepare the aerobic microbial material in the aerobic microbial reactor: mix graphite powder and sodium alginate with a weight ratio of 2:1, and then add activated aerobic microorganisms to obtain a mixture; soak the carrier in the mixture, and Under the condition that the vibration frequency is 200Hz, vibrate for 20min.

[0036] Prepare the anaerobic microbial material in the anaerobic microbial reactor: mix graphite powder and sodium alginate with a weight ratio of 2:1, and then add activated anaerobic microorganisms to obtain a mixture; soak the carrier in the mixture, and Under the condition that the vibration frequency is 150Hz, vibrate for 25min.

[0037] After coarse filtration, the sewage is passed into the aerobic microbial reactor for primary biological treatment. The flow rate of the sewage flowing through the aerobic microbial reactor is 10m / h, and the temperature of the aerobic microbial reactor can be controlled at 30°C. After the primary biological treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com