Amorphous alloy transformer containing nanometer iron powder

A technology of amorphous alloy and nano-iron powder, applied in inductors, transformers/inductor cores, transformers, etc. Low magnetic permeability and other problems, to achieve the effect of reducing energy consumption, reducing excitation power, and high initial magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

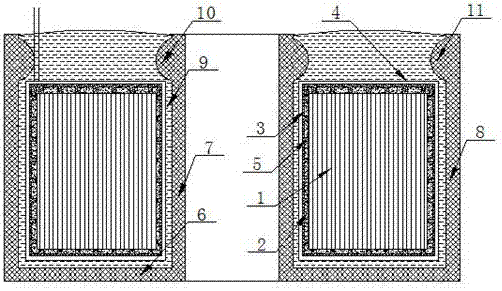

[0018] refer to figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of the present invention.

[0019] like figure 1 As shown, an amorphous alloy transformer containing nano-iron powder includes a transformer composite core, and the transformer composite core includes a ring-shaped amorphous alloy core 1 and is coated on the amorphous alloy magnetic core. Nano iron powder 2 on the surface of the core 1.

[0020] Specifically, the nano iron powder 2 contains the following elements by mass percentage: 12%-14% of neodymium element, 2.2%-2.5% of boron element, 0.05%-0.10% of dysprosium element, 0.6%-0.8% of cobalt element, copper element 0.5%~0.6%, gallium element 0.35%~0.45%, zirconium element 0.6%~0.7%, titanium element 0.2%~1.5%, iron element in the balance. The preparation method of described nano-iron powder 2 is:

[0021] Dissolve neodymium acetylacetonate, iron acetylacetonate and ethyl borate in absolute ethanol to prepare solution A, dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com