A breathable and highly elastic single-electrode triboelectric nanogenerator and its preparation method

A nanogenerator and single-electrode technology, applied in chemical instruments and methods, conductive/antistatic filament manufacturing, rayon manufacturing, etc., to achieve wide application prospects, simple preparation process, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

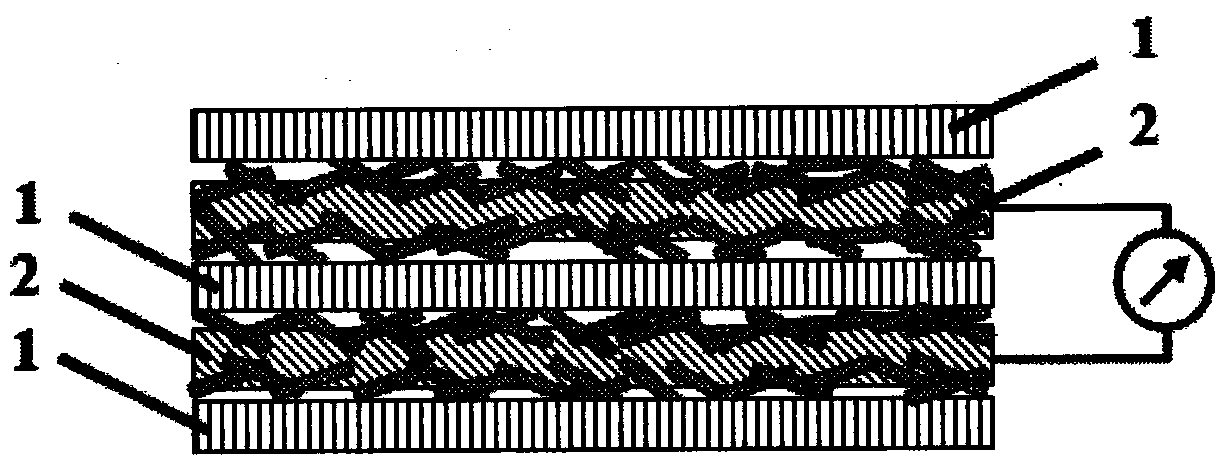

[0034] A breathable and high-elastic single-electrode triboelectric nanogenerator comprises high-elastic nanofiber membranes, conductive nanofiber membranes, high-elastic nanofiber membranes, conductive nanofiber membranes and high-elastic nanofiber membranes arranged in sequence from top to bottom. The tensile elastic elongation of the high elastic nanofiber membrane is 200-250%, and the tensile elastic recovery is 91-94%.

[0035] The preparation method of the breathable high-elastic single-electrode triboelectric nanogenerator is as follows:

[0036]The first step: add 5.4g polyether polyurethane (Elastollan1195A50, BASF, Germany) and 0.6g polytetrafluoroethylene micro-nano particles (Solvay XPP-552, average particle size 3.3μm) to 24.0g N, N-dimethyl In base formamide solvent, stirred at room temperature for 12 h and ultrasonicated in a 300W ultrasonic instrument for 1 h to form a homogeneous and stable solution. Then it was added to the electrospinning device for electro...

Embodiment 2

[0040] A breathable and high-elastic single-electrode triboelectric nanogenerator comprises high-elastic nanofiber membranes, conductive nanofiber membranes, high-elastic nanofiber membranes, conductive nanofiber membranes and high-elastic nanofiber membranes arranged in sequence from top to bottom. The tensile elastic elongation of the high elastic nanofiber membrane is 180-220%, and the tensile elastic recovery is 85-90%.

[0041] The preparation method of the breathable high-elastic single-electrode triboelectric nanogenerator is as follows:

[0042] The first step: add 4.2g polyester polyurethane (ElastollanR2000 of BASF, Germany) and 0.4g silica nanoparticles (Aladdin, product number S104599, average particle diameter 7~40nm) to 25.4g N , N-dimethylformamide solvent, stirred at room temperature for 12h and sonicated in a 200W ultrasonic instrument for 1.5h to form a uniform and stable solution. Then it was added to the electrospinning device for electrospinning to prepar...

Embodiment 3

[0047] A breathable and high-elastic single-electrode triboelectric nanogenerator comprises high-elastic nanofiber membranes, conductive nanofiber membranes, high-elastic nanofiber membranes, conductive nanofiber membranes and high-elastic nanofiber membranes arranged in sequence from top to bottom. The tensile elastic elongation of the high elastic nanofiber membrane is 160-220%, and the tensile elastic recovery is 85-96%.

[0048] The preparation method of the breathable high-elastic single-electrode triboelectric nanogenerator is as follows:

[0049] The first step: 6.6g polyester polyurethane (German BASF Elastollan1095A) and 0.8g titanium dioxide nanoparticles (Aladdin, product number T104950, average particle diameter 100nm) are added to 22.6g N, N-dimethylacetamide solvent, Stir at room temperature for 10 h and sonicate for 0.5 h in a 500W ultrasonic instrument to form a uniform and stable solution. Then it was added to the electrospinning device for electrospinning to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com