A kind of preparation method of sesame lignan extract

A technology of extract and lignan, applied in the field of preparation of sesame lignan extract, can solve the problems of high cost of sesamin, cumbersome steps, difficult industrialization, etc., achieves preventing or inhibiting oxidative rancidity, reducing waste discharge, The effect of increasing health functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

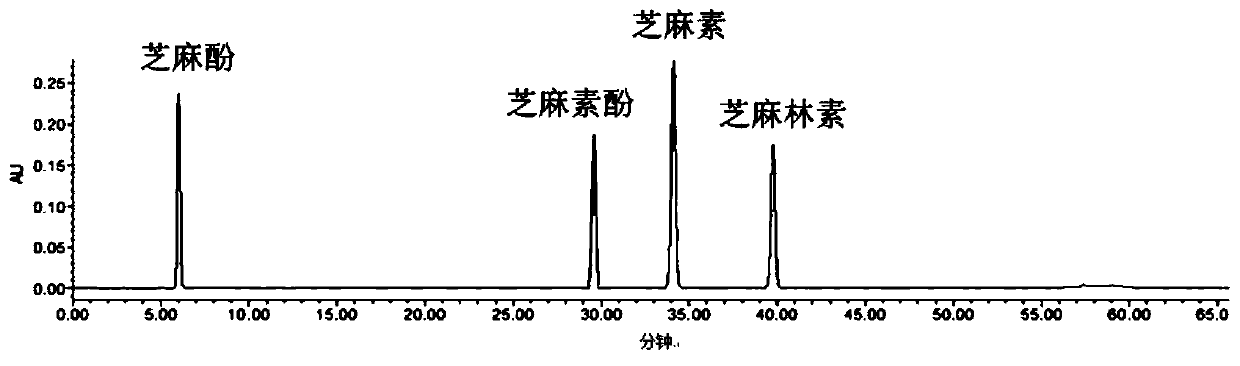

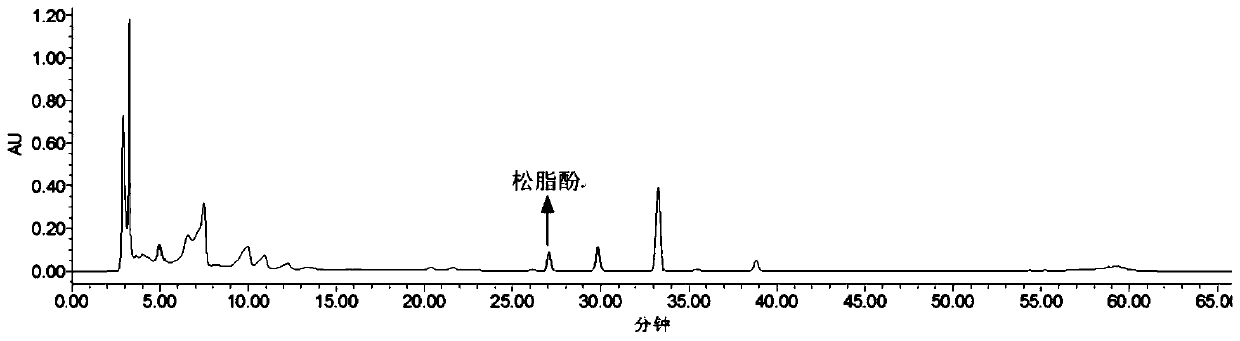

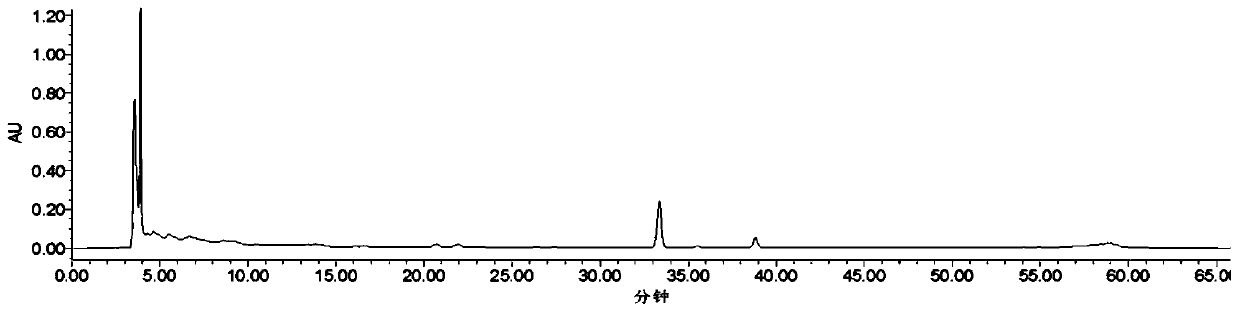

Embodiment 1

[0045] Weigh 50g of cold-pressed sesame cake → dry at 60°C → crush and sieve at 70 mesh → add 800mL of acidified ethanol solution (hydrogen chloride mass fraction 2%, water mass fraction 5.4%, ethanol mass fraction 92.6%) ultrasonic microwave extractor extraction , microwave power 500W, ultrasonic power 500W, extraction temperature 60°C, extraction time 20min → 5000r / min centrifugation, 50°C rotary evaporation to obtain crude sesame lignan extract 2.36g → 200mL n-hexane extraction 2 times and combined extracts → 45 ℃, rotary evaporating, concentrating and drying→weighing to obtain 0.67g of sesame lignan extract (that is, the extraction rate is 1.34%), and through HPLC analysis, it contains 12.4mg of sesamol (that is, the content is 1.85%), 10.5mg of pinoresinol ( 1.57%), sesaminol 25.7mg (i.e. the content is 3.84%), sesamin 86.3mg (i.e. the content is 12.88%), sesamolin 16.2mg (i.e. the content is 2.42%), the above total lignans 151.1mg ( That is, the content is 22.55%) → add ...

Embodiment 2

[0050] Weigh 50g of cold-pressed white sesame cake → dry at 50°C → crush and sieve at 60 mesh → add 500mL of acidified ethanol solution (hydrogen chloride mass fraction 1%, water mass fraction 2.7%, ethanol mass fraction 96.3%) ultrasonic microwave extractor Extraction, microwave power 300W, ultrasonic power 300W; extraction temperature 50°C, extraction time 10min→5000r / min centrifugation to obtain the supernatant, 45°C rotary evaporation to dryness to obtain crude sesame lignan extract 1.92g→150mL n-hexane extraction After 2 times, the extracts were combined → concentrated and dried by rotary evaporation at 45°C → sesame lignan extract → weighed to obtain 0.51g of a light yellow extract (that is, the extraction rate was 1.03%), which contained 6.3mg of sesamol ( That is, the content is 1.23%), pinoresinol 7.7mg (1.51%), sesamol 18.5mg (that is, the content is 3.63%), sesamin 57.9mg (that is, the content is 11.35%), sesamolin 13.8mg (that is, the content is 2.71%), above-menti...

Embodiment 3

[0053] Weigh 50g of cold-pressed white sesame cake → dry at 55°C → crush and sieve at 80 mesh → add 1000mL of acidified ethanol solution (3% hydrogen chloride mass fraction, 8.1% water mass fraction, 88.9% ethanol mass fraction) ultrasonic microwave extractor Extraction, microwave power 600W; ultrasonic power 600W; extraction temperature 70°C, extraction time 30min→5000r / min centrifugation to obtain the supernatant, 45°C rotary evaporation to dryness to obtain crude sesame lignan extract 2.79g→170mL n-hexane extraction After 3 times, the extracts were combined → concentrated and dried by rotary evaporation at 45 ° C → sesame lignan extract → weighed to obtain 0.79 g of light yellow sesame lignan extract (ie, the extraction rate was 1.58%), which contained sesame phenol 15.5mg (ie content 1.96%), pinoresinol 14.9mg (1.89%), sesamol 33.6mg (ie content 4.25%), sesamin 116.8mg (ie content 14.78%), sesamol 22.6mg (that is, the content is 2.86%), the above-mentioned total lignans 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com