Phosphorus nitrogen intumescent flame retardant and its preparation method and use

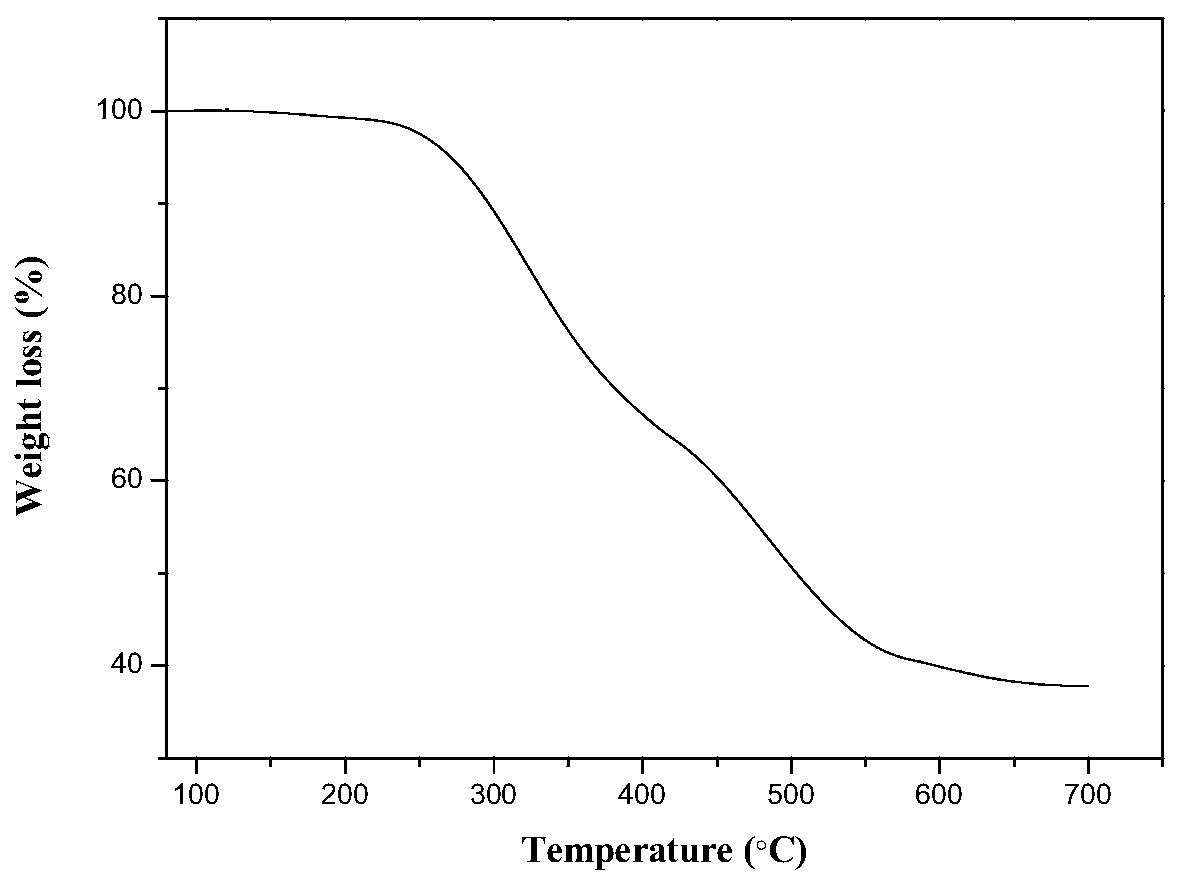

An intumescent flame retardant, phosphorus-nitrogen technology, applied in the field of flame-retardant materials, can solve the problems of poor thermal stability, poor polymer compatibility, low molecular weight of phosphorus-nitrogen flame retardants, etc., to improve flame retardant performance , large molecular weight, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

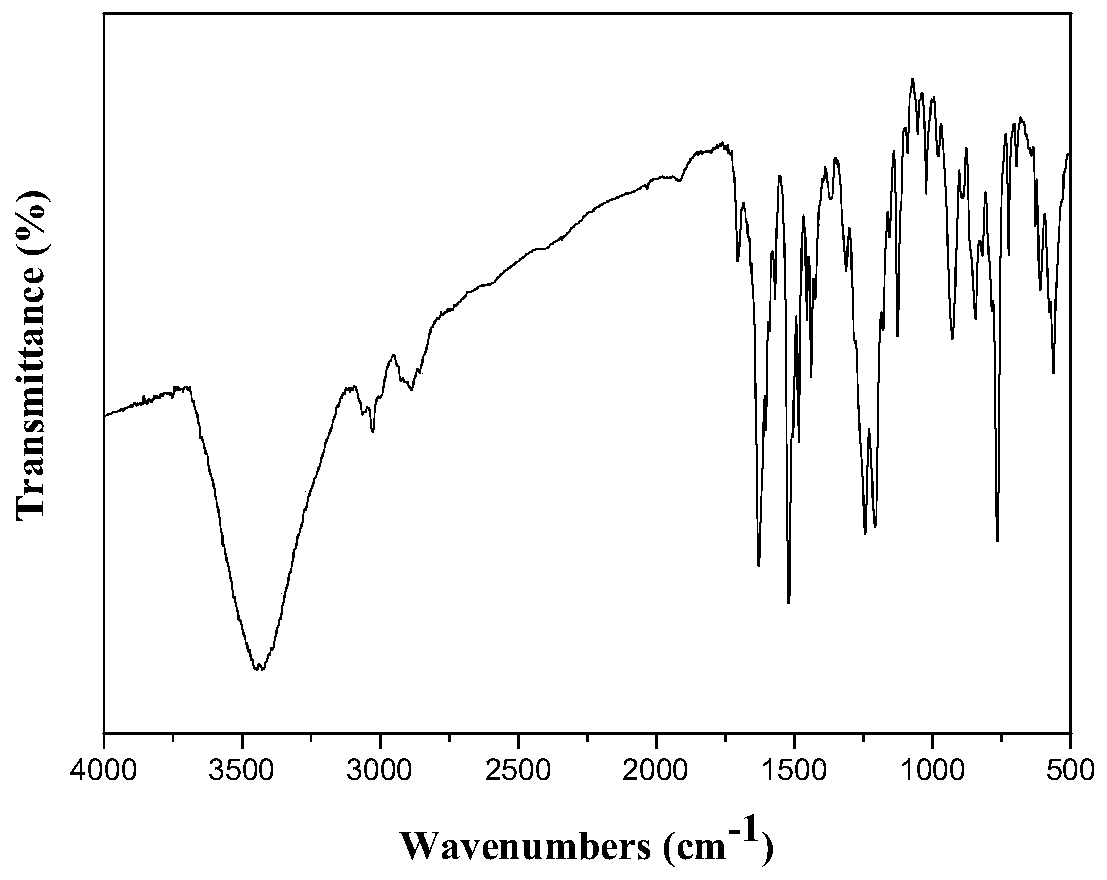

[0030] This embodiment relates to a preparation method of a phosphorus-nitrogen intumescent flame retardant, which comprises the following steps:

[0031] Dissolve 0.03mol of terephthalaldehyde in 80mL of absolute ethanol to obtain a reaction solution, add it to a 500mL three-neck flask, then blow in nitrogen and raise the temperature to 60°C, dissolve 0.03mol of DDM in 80mL of absolute ethanol, and turn on the magnetic stirring The device was stirred at a speed of 300rpm, and then added dropwise to the above reaction solution, heated to reflux temperature and continued to react for 4 hours, then cooled to room temperature, and then 0.06mol DOPO dissolved in 100mL of absolute ethanol was slowly added dropwise to the above After reacting in the solution for one hour, raise the temperature to reflux temperature and continue to react for 8 hours, take it out, wash, dry and grind to obtain yellow powder of high-efficiency phosphorus-nitrogen expansion flame retardant.

[0032] The...

Embodiment 2

[0034] This embodiment relates to a preparation method of the phosphorus-nitrogen intumescent flame retardant flame-retardant polycaprolactam obtained in Example 1, which comprises the following steps:

[0035] The flame retardant accounting for 10% of the total mass percentage of flame-retardant polycaprolactam and the polycaprolactam accounting for 90% are put into a mixer and mixed uniformly, and then the flame retardant and polycaprolactam resin are melt-blended, injected, cooled, and cut. After pelleting, flame-retardant polycaprolactam pellets with a flame-retardant grade of UL94V-1 (3.2mm) can be obtained.

Embodiment 3

[0037] This embodiment relates to a preparation method of the phosphorus-nitrogen intumescent flame retardant flame-retardant polycaprolactam obtained in Example 1, which comprises the following steps:

[0038] The flame retardant accounting for 15% of the total mass percentage of flame-retardant polycaprolactam and the polycaprolactam accounting for 85% are put into a mixer and mixed uniformly, and then the flame retardant and polycaprolactam resin are melt-blended, injected, cooled, and cut. After granulation, the flame-retardant polycaprolactam pellets with a flame-retardant grade of UL94V-0 (3.2mm) can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com