Viologen/cellulose nanocrystal composite film, preparation method of same, and detachable electrochromic device

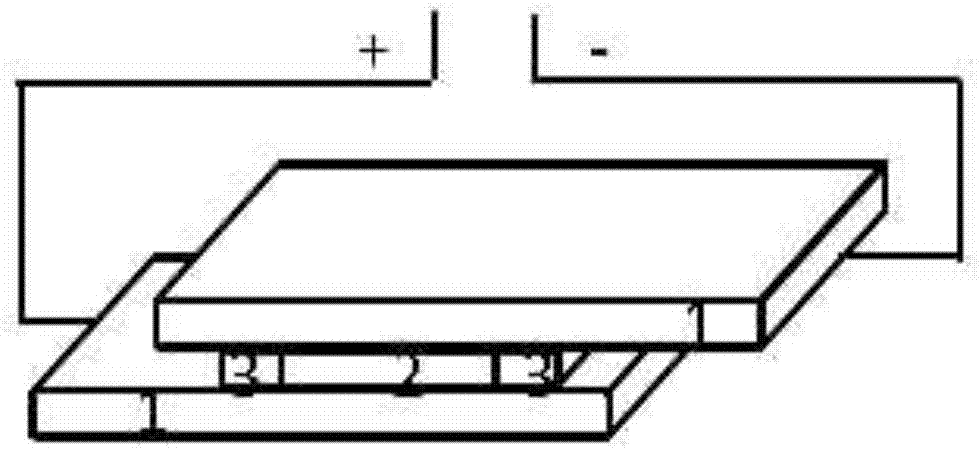

An electrochromic device and nanocrystal composite technology, which can be used in instruments, optics, nonlinear optics, etc., can solve the problems of difficult separation and loss of the electrochromic layer and the conductive matrix, and achieve good electrochromic performance and low cost. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

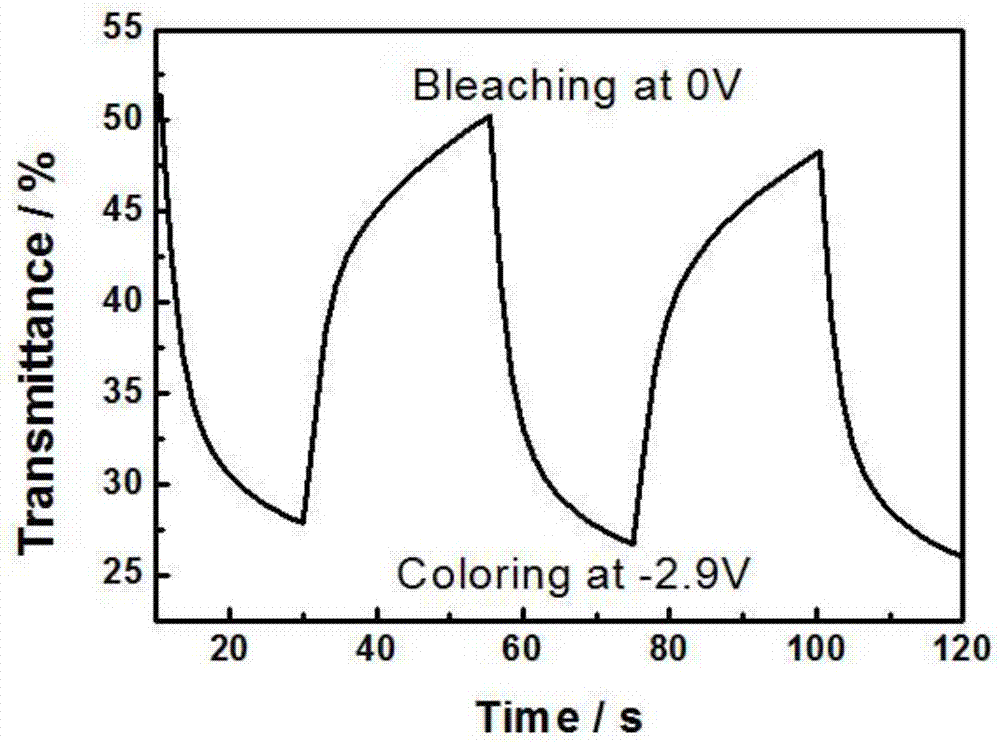

Embodiment 1

[0045] Put 20g of pulp raw material (provided by Hubei Chemical Fiber Cellulose Co., Ltd., with a degree of polymerization of 700) in a water bath at 50°C, slowly add concentrated sulfuric acid (commercially available) with a concentration of 64% for acidolysis, and add ten times of The reaction was terminated with deionized water, and after standing for 24 hours, the supernatant was discarded, and the lower layer was centrifuged at a speed of 8000rpm for 10 minutes, centrifuged 6 times, and the final suspension was dialyzed for 5 days, and placed in the refrigerator for later use. Concentration 10mg / ml. Take the cellulose nanocrystal suspension prepared above and concentrate it to 35 mg / ml by 50 ℃ rotary steaming method, take 40 parts by weight of cellulose nanocrystal, then add 0.01M methyl viologen (take methyl viologen parts by weight) and 0.1M potassium chloride (10 parts by weight of potassium chloride), after mixing the three evenly with a micro-vortex mixer, spread the...

Embodiment 2

[0047] The process flow is the same as in Example 1, except that the cellulose nanocrystal suspension prepared above is concentrated to 35 mg / ml by rotary steaming at 50°C, and the weight of cellulose nanocrystals is 50 parts, and then 0.01M Methyl viologen (100 parts by weight of methyl viologen) and 0.1M potassium chloride (5 parts by weight of potassium chloride), after mixing the three evenly with a micro-vortex mixer, spread drying in a petri dish at 23° C. and a relative humidity of 50-60 percent to obtain a viologen / cellulose nanocrystal composite film.

Embodiment 3

[0049] The process flow is the same as in Example 1, except that the cellulose nanocrystal suspension prepared above is concentrated to 35 mg / ml by rotary steaming at 50°C, and 25 parts by weight of the cellulose nanocrystal are taken, and then 0.08M Methyl viologen (100 parts by weight of methyl viologen) and 0.1M potassium chloride (5 parts by weight of potassium chloride), after mixing the three evenly with a micro-vortex mixer, spread drying in a petri dish at 23° C. and a relative humidity of 50-60 percent to obtain a viologen / cellulose nanocrystal composite film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com