Method for preparing lignin-based phenolic resin adhesive and co-producing quickly-composted fertilizer returned into field by utilizing fiber ethanol fermentation residues

A fermentation residue and cellulosic ethanol technology, applied in adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problems of long gelation time and short storage days of lignin-based phenolic resins, and achieve Effects of improving economic competitiveness, extending storage days, and shortening gel time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

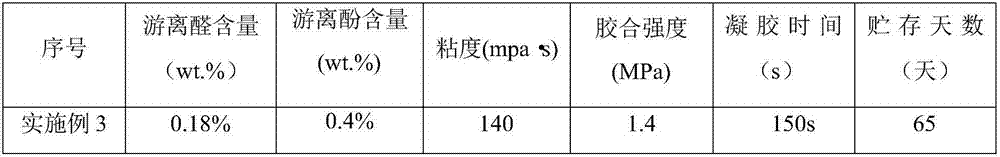

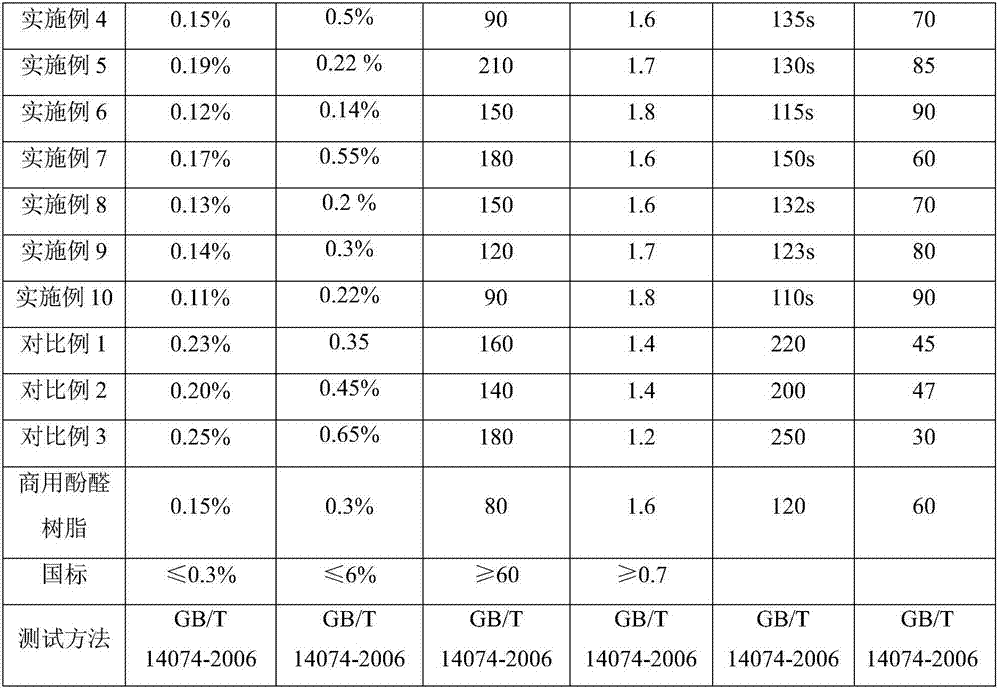

Examples

Embodiment 1

[0025] Take 50 kg of corn stalk fiber ethanol fermentation residue, add 500 kg of 5 wt.% NaOH aqueous solution, and stir at 60° C. for 20 min to carry out alkali extraction of lignin.

[0026] After the reaction, the obtained solid-liquid mixture was put into a filter press for solid-liquid separation to obtain 540 kg of alkali extract and 10 kg of solid residue. Add 0.3 kg of HM straw decomposing agent to the solid residue for composting treatment, the decomposing temperature is normal temperature, and the decomposing time is 20 days, so as to realize the reuse of biomass in the field. The ultrafiltration membrane with a molecular weight cut-off of 10000Da is used to carry out ultrafiltration on the alkali extract, the ultrafiltration pressure is 0.6MPa, and the ultrafiltration stirring speed is 500rpm to obtain the retentate A1 and the permeate A2; the permeate A2 continues to use the molecular weight cut-off Perform ultrafiltration for a 5000Da ultrafiltration membrane to o...

Embodiment 2

[0029] Take 100 kg of corn straw fiber ethanol fermentation residue, add 700 kg of 4 wt.% NaOH aqueous solution, stir at 70° C. for 30 min to carry out alkali extraction of lignin.

[0030] After the reaction, the obtained solid-liquid mixture was put into a filter press for solid-liquid separation to obtain 785kg of alkali extract and 15kg of solid residue, and the solid residue was added with 0.4kg HM straw decomposing agent for composting. The decomposing temperature is normal temperature, and the decomposing time is 15 days, so as to realize the return and reuse of biomass. The ultrafiltration membrane with a molecular weight cut-off of 10000Da is used for ultrafiltration of the alkali extract, the ultrafiltration pressure is 0.4MPa, and the ultrafiltration stirring speed is 400rpm to obtain the retentate A1 and the permeate A2; the permeate A2 continues to use the molecular weight cut-off Perform ultrafiltration for a 5000Da ultrafiltration membrane to obtain the retentat...

Embodiment 3

[0033] Take 30 kg of lignin solution A with a molecular weight greater than 10,000 Da in Example 1 and add it to a glass reactor, then add 9 kg of molten phenol, set the stirring speed of the mechanical stirring tank to 650 rpm, and react at 90 ° C for 2 hours to obtain a phenolized modified lignin solution. Cool to 80°C, then add 13.7kg of 37wt.% formaldehyde aqueous solution, react at 80°C for 2h, then cool down to 65°C, add 0.9kg of urea and stir for 0.5h. Cool to 40°C and discharge to obtain a lignin-based phenolic resin adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com