Dust and smoke suppressor for mines

A smoke suppressant and mining technology, applied in dust prevention, mining equipment, safety devices, etc., can solve problems such as unsatisfactory dust and smoke removal effects, difficult to obtain raw materials, expensive dust and smoke suppressants, etc., to achieve a dust suppression cycle Long, good dust suppression effect, easy to obtain the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

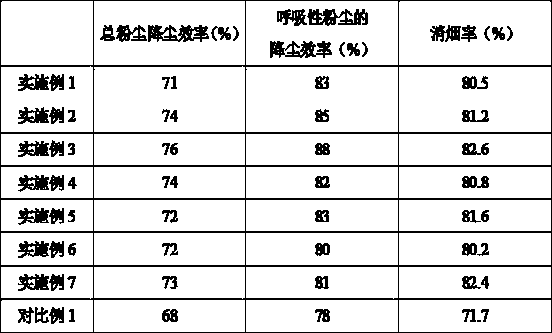

Embodiment 1

[0057] The dust and smoke suppressant used in mines consists of the following raw materials in parts by weight:

[0058] 15 parts of alkylphenol polyoxyethylene ether,

[0059] α-olefin sulfonate 25 parts,

[0060] Alkyl amidopropyl betaine 15 parts,

[0061] Calcium chloride 1 part,

[0062] Calcium glycinate 0.5 part,

[0063] 0.05 parts of sodium 2-methylisocitrate,

[0064] Sodium polyglutamate 1 part,

[0065] 1,2-propanediol 5 parts,

[0066] 100 parts of water,

[0067] Wherein the alkylphenol polyoxyethylene ether is a mixture of octylphenol polyoxyethylene ether and dinonylphenol polyoxyethylene ether, the mass of the octylphenol polyoxyethylene ether and dinonylphenol polyoxyethylene ether The ratio is 1:2; the α-olefin sulfonate is sodium α-olefin sulfonate; the alkylamidopropyl betaine is lauryl amidopropyl betaine.

Embodiment 2

[0069] The dust and smoke suppressant used in mines consists of the following raw materials in parts by weight:

[0070] 22 parts of alkylphenol polyoxyethylene ether,

[0071] α-olefin sulfonate 20 parts,

[0072] Alkyl amidopropyl betaine 20 parts,

[0073] Calcium chloride 0.8 part,

[0074] Calcium glycinate 0.8 parts,

[0075] 0.06 parts of sodium 2-methylisocitrate,

[0076] Sodium polyglutamate 3 parts,

[0077] 1,2-propanediol 3 parts,

[0078] 100 parts of water,

[0079] Wherein the alkylphenol polyoxyethylene ether is a mixture of octylphenol polyoxyethylene ether and dinonylphenol polyoxyethylene ether, the mass of the octylphenol polyoxyethylene ether and dinonylphenol polyoxyethylene ether The ratio is 1:2; the α-olefin sulfonate is sodium α-olefin sulfonate; the alkylamidopropyl betaine is lauryl amidopropyl betaine.

Embodiment 3

[0081] The dust and smoke suppressant used in mines consists of the following raw materials in parts by weight:

[0082] 20 parts of alkylphenol polyoxyethylene ether,

[0083] α-olefin sulfonate 22 parts,

[0084] Alkyl amidopropyl betaine 18 parts,

[0085] Calcium chloride 0.9 part,

[0086] Calcium glycinate 0.8 parts,

[0087] 0.07 part of sodium 2-methylisocitrate,

[0088] Sodium polyglutamate 4 parts,

[0089] 1,2-propanediol 2 parts,

[0090] 100 parts of water,

[0091] Wherein the alkylphenol polyoxyethylene ether is a mixture of octylphenol polyoxyethylene ether and dinonylphenol polyoxyethylene ether, the mass of the octylphenol polyoxyethylene ether and dinonylphenol polyoxyethylene ether The ratio is 1:2; the α-olefin sulfonate is sodium α-olefin sulfonate; the alkylamidopropyl betaine is lauryl amidopropyl betaine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com