Engineering strain expressing beta-mannase as well as fermenting method and enzymolysis method thereof

A technology of mannanase and engineering strains, applied in the field of enzyme engineering, can solve the problems of reducing the digestibility of other nutrients, reducing the apparent digestibility of energy and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Isolation and identification of high-production β-mannanase strains

[0038] 0.1 g of soil samples collected from the suburbs of Shenyang City were weighed and suspended by shaking with 100 ml of sterilized water. After dissolving, 10-fold serial dilution was carried out, and 100 μl of PDA medium (containing 0.5 mg konjac flour / plate) was applied to each gradient, and dried on an ultra-clean bench, and cultured in a 30°C incubator upside down for 2-3 days. Stratify the well-growing colony on a PDA plate, and plant it on another PDA plate (containing 0.5mg / plate of konjac flour) at the same time. After the plate colonies grow well, stain with 0.1% Congo red for 1 hour, add 1M NaCl, shake gently on a shaker, and decolorize for 30 minutes. Observe the size of the transparent circle.

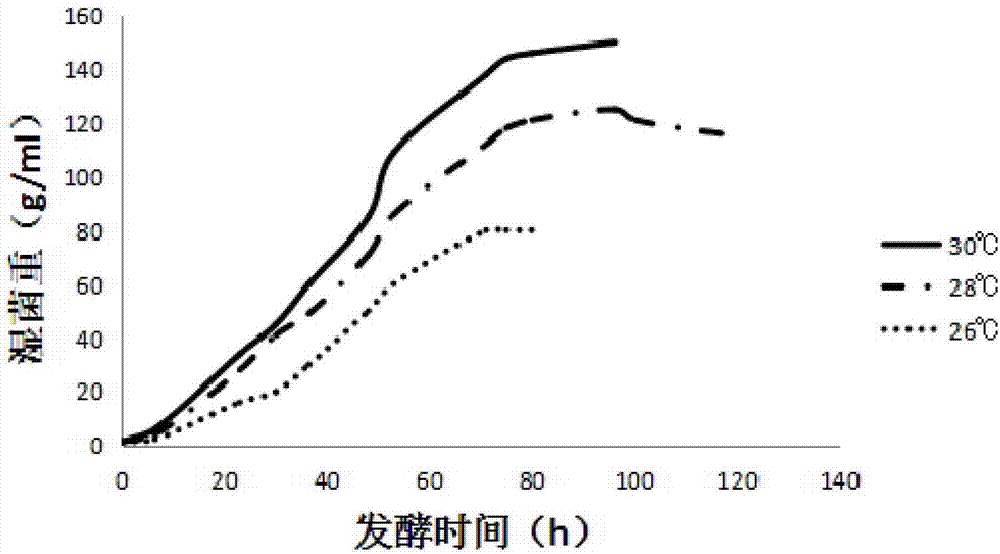

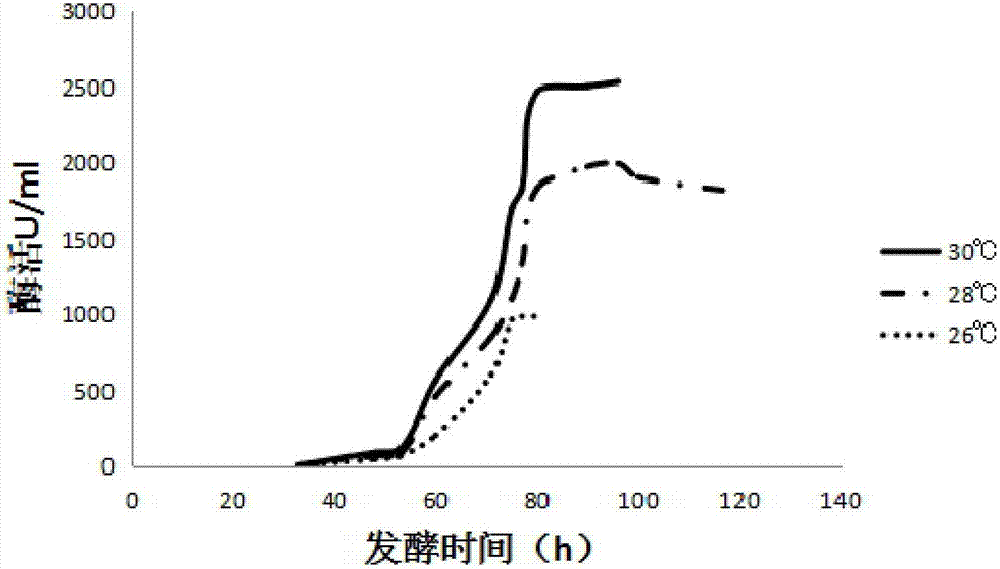

[0039] Select colonies with large transparent circles to carry out fermentation culture of shake flask liquid PDA (containing 0.03 g / mL konjac flour), and shake culture at 200 rp...

Embodiment 2

[0040] Example 2: Cloning of β-mannanase gene

[0041] The total genomic DNA of Aspergillus oryzae was extracted with a kit. Primers were designed according to the β-mannanase gene sequence reported by NCBI (F: 5-ATGATACTTTTCCAGCTTTTTG-3; R: 5-TCACTTCTCCCAAAACCAACCAC-3). Using about 100ng of total DNA as a template, PCR amplifies the target gene. The amplification conditions are: denaturation at 94°C for 30s, annealing at 55°C for 30s, extension at 72°C for 1.5min, 35 cycles, 0.8% agarose gel electrophoresis to detect PCR amplification As a result, a band with a size of about 1350bp can be seen, which is consistent with the predicted size of the target gene. The PCR product was directly sequenced, and the full-length sequence was 1365bp, encoding a 454aa protein.

Embodiment 3

[0042] Example 3: Efficient secretory expression of β-mannanase

[0043] Design primers (F-E: 5-CGGAATTCATGATACTTTTCCAGC-3; R-X: 5-CGTCTAGATCACTTCTCCCAAACC-3), and use the PCR product obtained in Example 2 as a template to carry out PCR amplification. The amplification conditions are: denaturation at 94°C for 30s, annealing at 55°C for 30s , 72°C for 1.5 min, 35 cycles, and 0.8% agarose gel electrophoresis to detect the PCR amplification results. The PCR product was purified with a DNA purification kit, the purified DNA was digested with EcoRI and XbaI, digested at 37°C overnight, purified again, and then ligated with the same digested vector pGAPzαA overnight at 16°C. Transform Escherichia coli Top10 competent cells, spread Zeocin-containing plates, and culture overnight at 37°C. Pick a single colony, culture in LB liquid medium, extract the plasmid, sequence and identify the sequence of the expression vector.

[0044] The constructed vector pGAP-mann was electroporated to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com