Method for improving hydrolytic efficiency of cellulose

A technology of cellulose and efficiency, which is applied in the field of improving the efficiency of cellulose hydrolysis, and can solve the problems affecting the total sugar yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

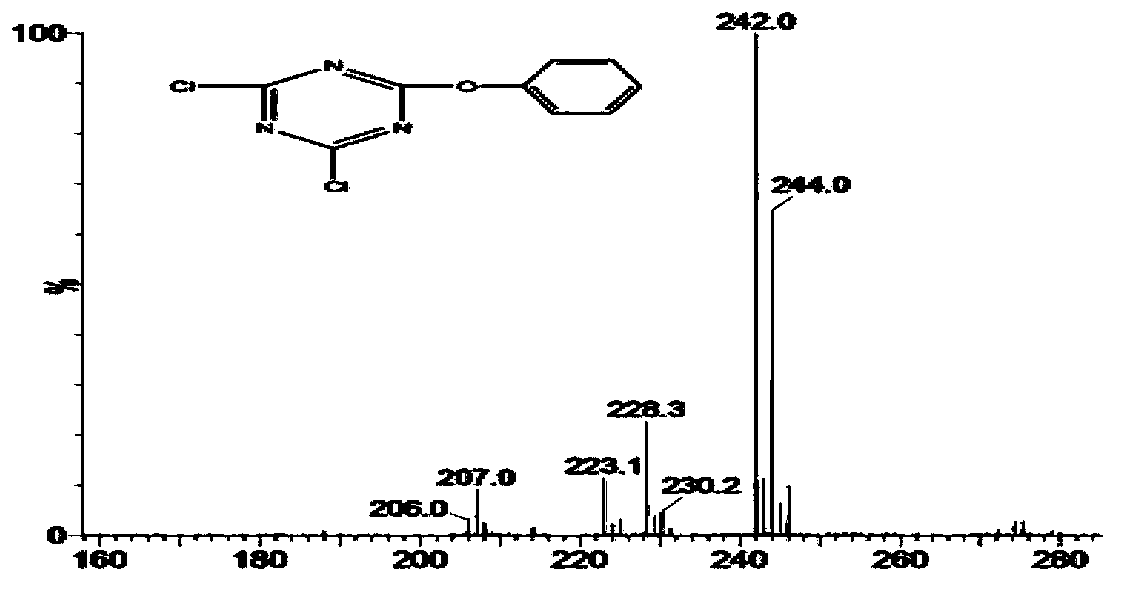

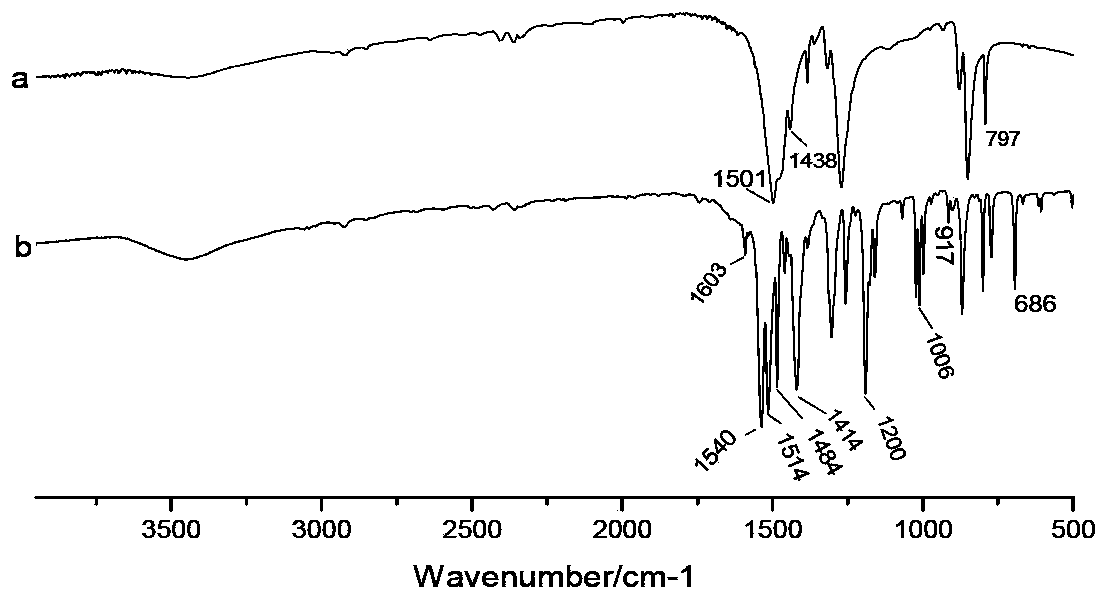

[0029] (1) Weigh 4 parts of cyanuric chloride into the reactor, add 40 parts of dichloromethane, and then stir in an ice-water bath; use 30 parts of 2 parts of phenol, 2 parts of anhydrous sodium carbonate and 0.1 part of anhydrous sodium sulfite After the water is dissolved, it is slowly dripped into the above system, and it lasts for 1 hour. Continue to react for 2 hours, stop the reaction, pour it into a separatory funnel, and let it stand for 1 hour. The crude product was obtained from methane, and the crude product was recrystallized from THF-water to obtain a white solid with a yield of 65.5%.

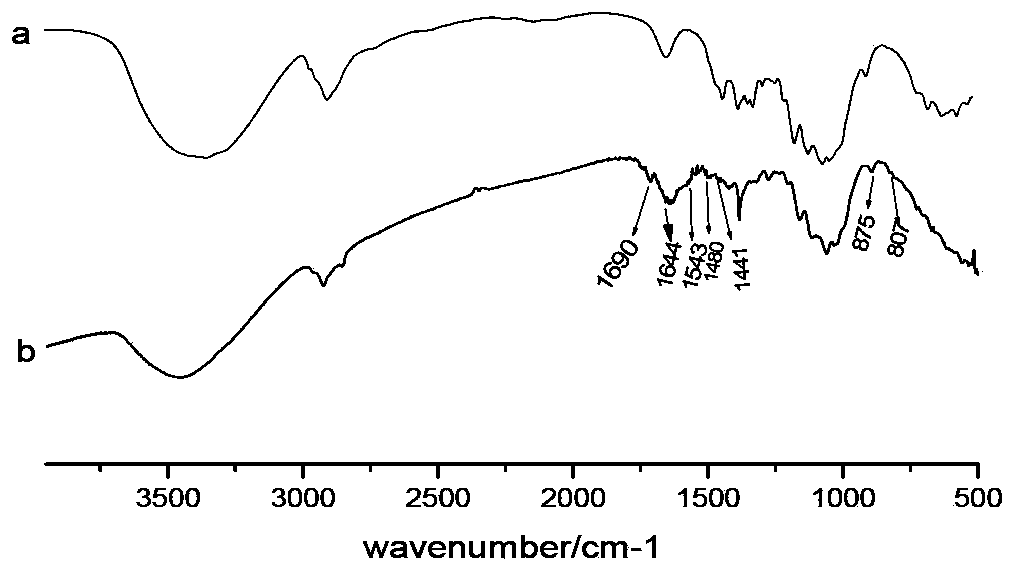

[0030] (2) Weigh 2 parts of cellulose into the reactor, add 10 parts of acetone; weigh the relative molar content (based on glucose ring) of 1 / 40 parts of modifier, and add 30 parts of acetone to dissolve it under stirring, And slowly drop it into the above system; use 10wt% NaOH as a catalyst, react at a temperature of 40°C for 3 hours, the product is filtered by suction and was...

Embodiment 2

[0033] (1) Weigh 2 parts of cyanuric chloride into the reactor, add 20 parts of dichloromethane, and then stir in an ice-water bath; use 30 parts of 1 part of phenol, 1 part of anhydrous sodium carbonate and 0.1 part of anhydrous sodium sulfite After the water is dissolved, it is slowly dripped into the above system, and it lasts for 1 hour. Continue to react for 2 hours, stop the reaction, pour it into a separatory funnel, and let it stand for 1 hour. The crude product was obtained from methane, and the crude product was recrystallized from THF-water to obtain a white solid with a yield of 75.5%.

[0034] (2) Weigh 2 parts of cellulose in the reactor, add 10 parts of acetone; weigh the relative molar content (based on glucose ring) as 1 / 20 modifier, add 30 parts of acetone to dissolve it under stirring, and Slowly drop into the above system; use 10wt% NaOH as a catalyst, react at a temperature of 40°C for 3 hours, the product is filtered by suction and washed with deionized w...

Embodiment 3

[0037] (1) Weigh 1 part of cyanuric chloride into the reactor, add 10 parts of dichloromethane, and then stir in an ice-water bath; use 30 parts of 1 part of phenol, 1 part of anhydrous sodium carbonate and 0.1 part of anhydrous sodium sulfite After the water is dissolved, it is slowly dropped into the above system, and it lasts for 1 hour. Continue to react for 2 hours, stop the reaction, pour it into a separatory funnel, and let it stand for 1 hour. The crude product was obtained from methane, and the crude product was recrystallized with tetrahydrofuran-water to obtain a white solid with a yield of 60.5%.

[0038] (2) Weigh 2 parts of cellulose into the reactor, add 10 parts of acetone; weigh the relative molar content (based on glucose ring) of 1 / 5 parts of modifier, and add 30 parts of acetone to dissolve it under stirring, And slowly drop it into the above system; use 10wt% NaOH as a catalyst, react at a temperature of 40°C for 3 hours, the product is filtered by suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com