A large-scale automated Panax notoginseng planting factory structure

A technology of Panax notoginseng and factory, applied in plant cultivation, building structure, climate change adaptation, etc., can solve problems such as difficult to apply reasonably and accurately control, high input cost, high cost, etc., to achieve precise and complete control , reduce the amount of energy-saving control, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

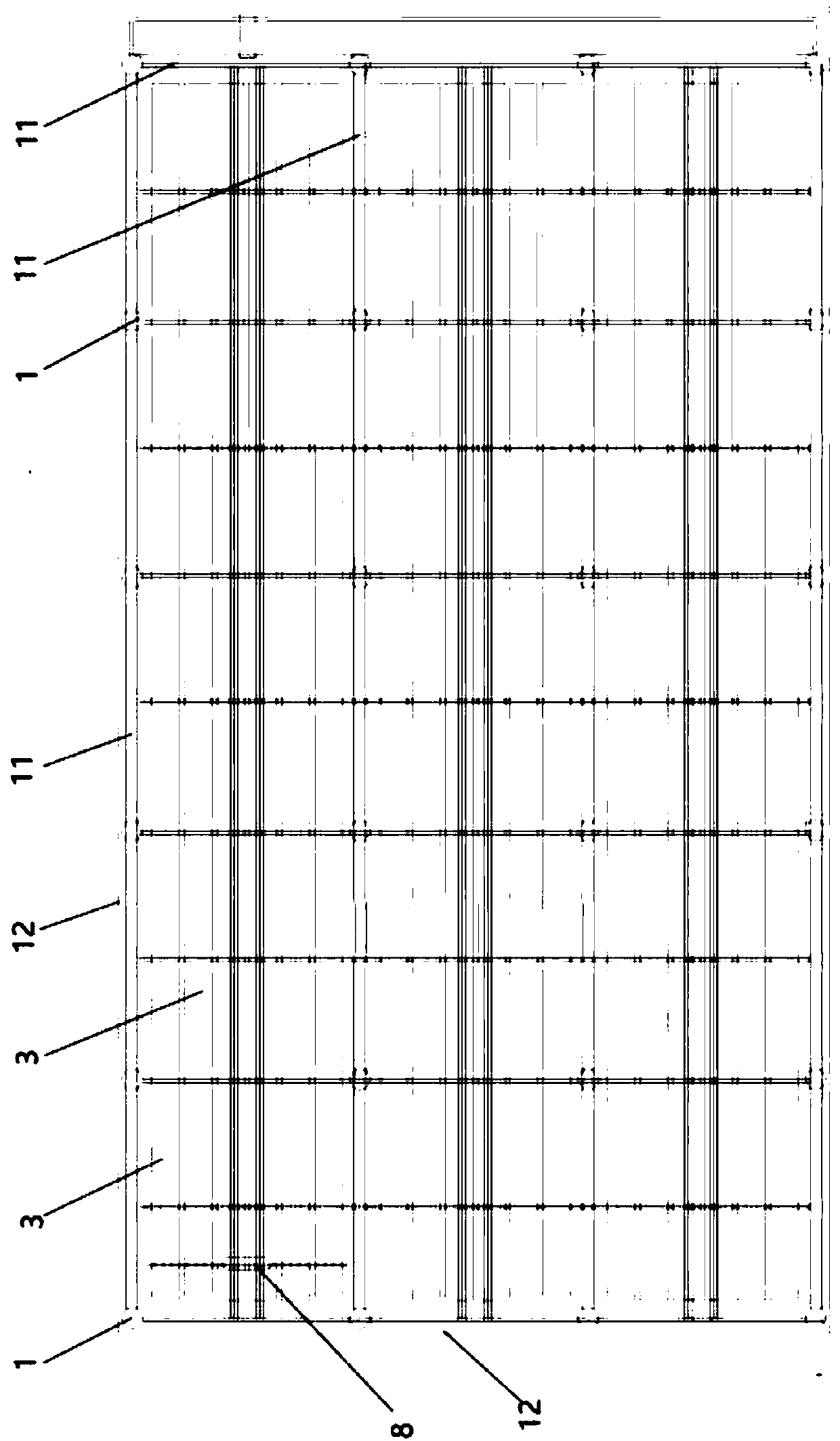

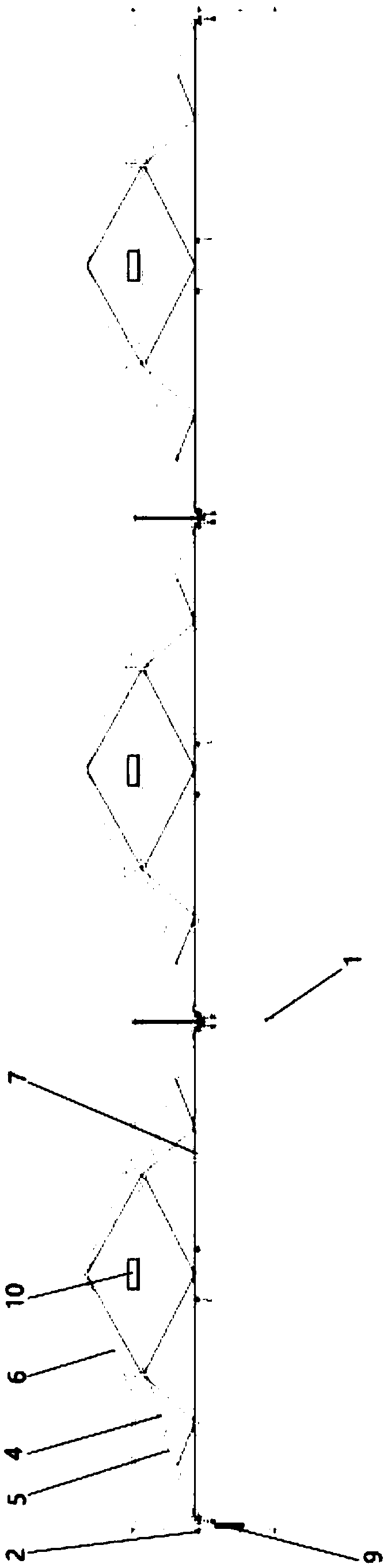

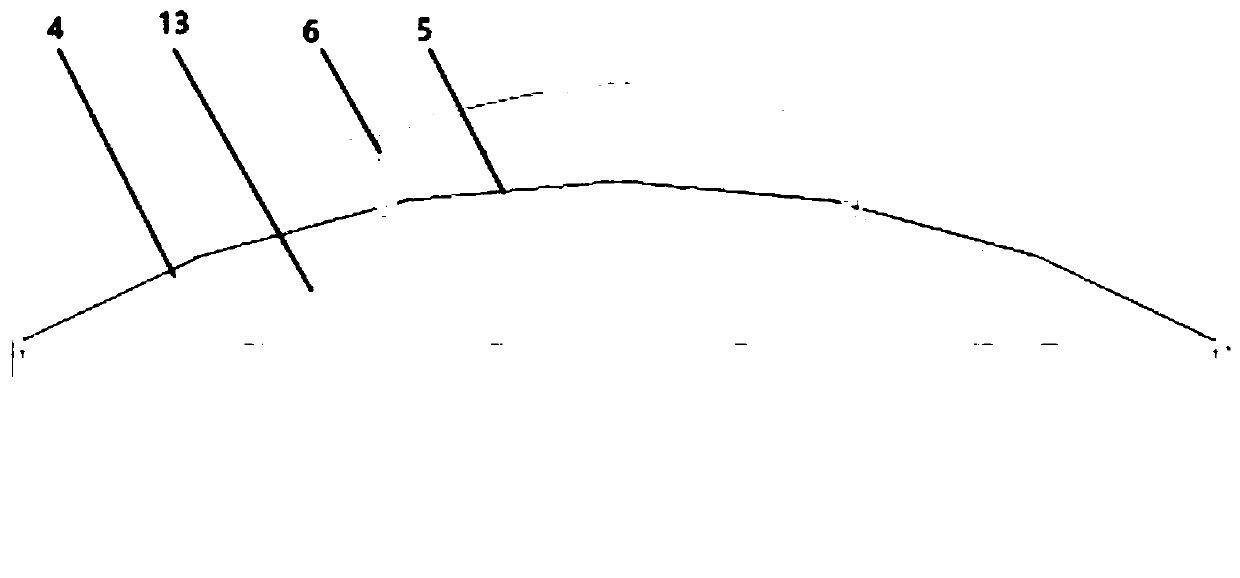

[0067] Embodiment 1: as Figure 1 ~ Figure 3 As shown, a large-scale automated Panax notoginseng planting factory structure: including several support columns 1, four-wall body of walls 12, several trusses 11, several top bridges 4, film 5, breathable ceiling 6, several groups of double-layer shades Net system 7, automatic sprinkler irrigation unit 8, ventilation window 9, ventilator 10, planting ridge 3 and automatic control system, wherein: support column 1 is vertically fixed on the ground and stands upward as a pillar supporting the entire factory structure, in several rows in the longitudinal direction Arranged, the outermost set of support columns 1 is connected with the four-wall wall 12, the four-wall wall 12 is used to form the outer wall of the factory, and several trusses 11 are fixed on the support column 1 to cover the planting ridge 3 At the top, the trusses 11 are alternately built into a rectangular frame to provide horizontal overall support. The top bridges 4...

Embodiment 2

[0068] Embodiment 2: On the basis of Embodiment 1, the factory structure also includes a built-in temperature and humidity sensor, a pH value sensor, and the temperature and humidity sensor and the pH value sensor are all connected to the automation control system. The automation control system has Wireless transmission display control function and control modules corresponding to each component; lane-dividing columns are fixed on the ground between every two adjacent planting ridges and on the ground on both sides of the entire planting ridge, and the lane-dividing columns separate the planting ridges For several planting roads arranged vertically, the height of the lane-dividing column is not lower than the thickness of the planting ridge, and the front surface of the lane-dividing column is fixed with a fixed track 39; the pH value sensor is used to insert into the soil to monitor the soil pH value, The temperature and humidity sensor is used to monitor the condition value o...

Embodiment 3

[0072] Embodiment 3: on the basis of embodiment 1, as Figure 6 ~ Figure 9 As shown, the automatic sprinkling irrigation unit 8 includes a working track 81 placed above the field, a sprinkler 82 placed on the working track 81, a traveling device is arranged above the sprinkler 82, and the traveling device is installed on the working track 81. Track 81 is that several rows are distributed side by side in parallel, and the same end of several rows of working tracks 81 is connected to a transfer track 83, and the traveling device is provided with a transfer device 84 that can run on the transfer track 83, and each of the working tracks 81 is Equipped with a water source interface 85 and a power interface 86, the water source interface 85 is connected to the sprinkler 82 through a pipeline, the power interface 86 is connected to the sprinkler 82 through a wire, and the sprinkler 82 and the transfer device 84 are connected to the control system. During use, both the power supply in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com