A multi-zone marine environment comprehensive simulation test device

An environmental test and marine environment technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of inability to realize high temperature and high humidity, salt spray, ultraviolet radiation erosion and corrosion, inability to accurately simulate the characteristics of tropical marine environments, and the method is too simple and other problems, to achieve the effect of uniform spraying and etching, compact structure and uniform irradiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

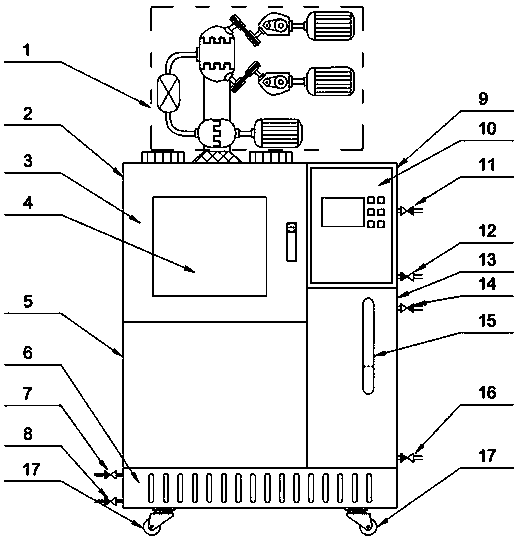

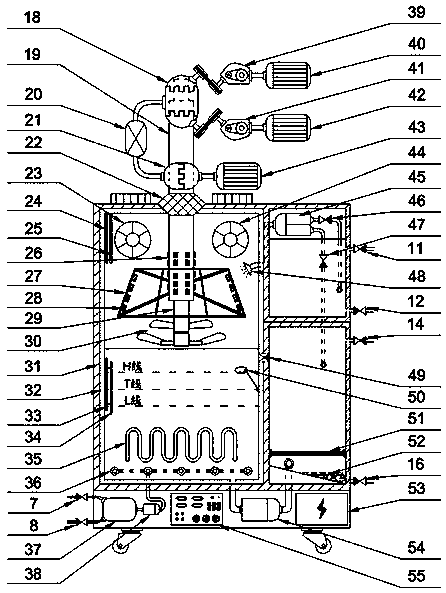

[0049] as attached Figure 1-4 As shown, the main body of the multi-zone marine environment comprehensive simulation test device is composed of a power system 1, an atmospheric environment test cabin 2, a solution environment test cabin 5, an electrical equipment cabin 6, a deionized water tank 9, and a supply tank 13 composition. A hatch 3 with an observation window 4 is arranged outside the atmospheric environment test cabin 2 . A control panel 10 is arranged outside the deionized water cabin, which is used for the preset of the test program and the indication of the running status of each component. The test program adopts a modular setting method, including the atmospheric zone test mode, high temperature and high humidity test mode, splash zone test mode, tidal range zone test mode, full immersion zone test mode and erosion corrosion test mode. A liquid level indicator window 15 is provided outside the replenishment liquid tank 13 to display the liquid level height of t...

Embodiment 2

[0053] When carrying out the atmospheric zone test, the test is set to the atmospheric zone test mode through the control panel 10, and the individual tests or combined tests of wetting, drying, ultraviolet radiation and salt spray are set. Set the cycle mode, duration and test period of each stage, and set the temperature and humidity of the atmospheric environment test chamber 2 in each stage. Set the external drive shaft speed changer 41 as a low speed.

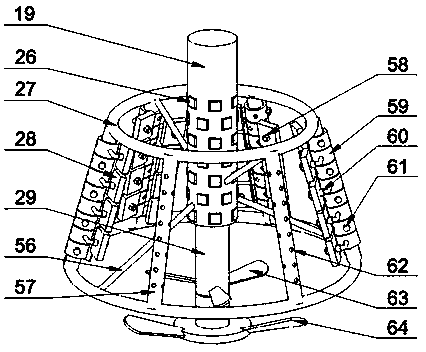

[0054] After starting the test, the sample holder 27 is maintained at the atmospheric test height. The contact converter 20 separates the horizontal contactor 21 and combines the vertical contactor 18, the lifting motor 43 and the inner transmission shaft rotation motor 40 are in a closed state, the outer transmission shaft rotation motor 42 is turned on, and the outer transmission shaft 19 drives the sample holder 27 according to the design. Rotate at a constant speed. During the wetting stage, the heating fan 23 is tur...

Embodiment 3

[0057] When carrying out the high-temperature and high-humidity test, the test is set to the high-temperature and high-humidity test mode through the control panel 10, and the temperature and humidity of the atmospheric environment test chamber 2 and the temperature of the solution environment test chamber 5 are set.

[0058] After starting the test, the sample holder 27 is maintained at the atmospheric test height. Lifting motor 43, inner transmission shaft rotating motor 40 and outer transmission shaft rotating motor 42 are all in closed state. The communication valve 49 is opened, and the test solution is injected into the solution environment test chamber 5 from the supply liquid tank 13 . When the float level sensor 50 reaches the reference level T line, the communication valve 49 is closed. The heating tube 35 is opened, and when the temperature monitored by the solution thermometer 33 reaches the set value, the heating tube 35 is closed, thereby assisting in increasing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com