Preparation method for wave absorbing material with high magnetic conductivity

A technology of wave absorbing material and high magnetic permeability, applied in the field of wave absorbing material, can solve the problem of reducing the uniformity of the proportion, and achieve the effect of reducing the ball milling time, good uniformity and low roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

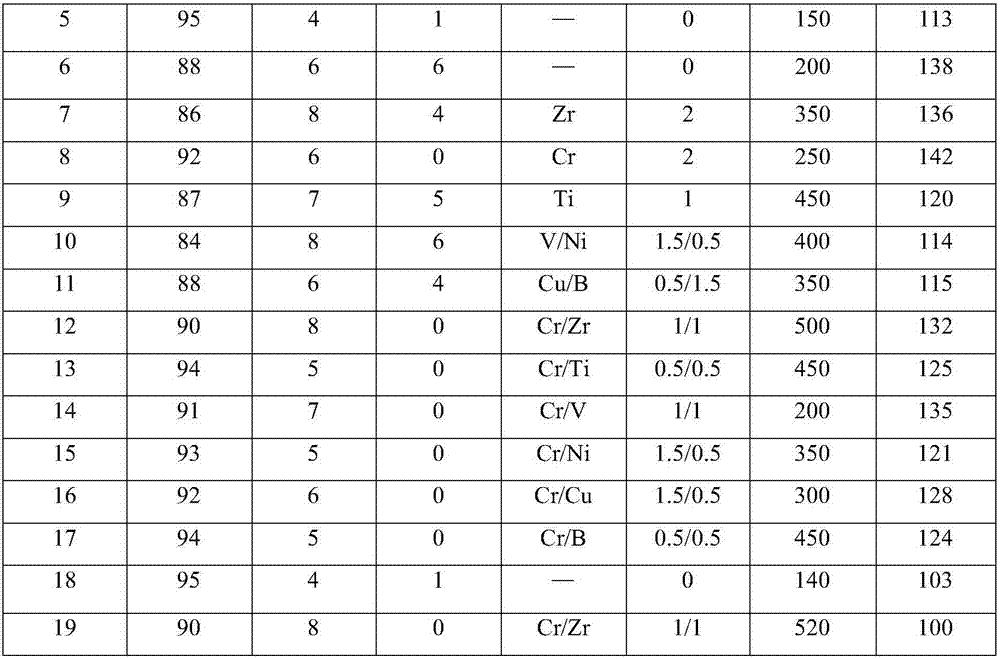

Examples

Embodiment 1

[0031] (1) Put the following raw materials Fe 86%, Si8%, and Al 6% into an intermediate frequency vacuum induction furnace with alumina as a crucible for smelting, and vacuumize to 10 -3 Pa, filled with high-purity argon until the pressure in the furnace is 5*10 4 Pa, use high power until the charge melts, then refine with low power for 5 minutes.

[0032] (2) Put the smelted FeSiAl master alloy into the crucible, wherein the diameter of the crucible nozzle is 0.5mm, the injection pressure is 4000Pa, and the vacuum is 5*10 -3 Pa, the alloy ingot is remelted by an induction coil under the protection of high-purity argon, and then is quickly sprayed onto a high-speed rotating roller to obtain a rapidly solidified sheet with a rapid quenching rate of 22m / s. At the same time, the flakes are pre-broken to less than 1mm.

[0033] (3) The pre-broken alloy powder is ball milled for 10 hours, the temperature in the ball mill cavity is 200°C, the ball-to-material ratio is 5:1, and the...

Embodiment 2

[0036] (1) Put the following raw materials Fe 90%, Si6%, and Al 4% into an intermediate frequency vacuum induction furnace with alumina as a crucible for smelting, and vacuumize to 10 -3 Pa, filled with high-purity argon until the pressure in the furnace is 5*10 4 Pa, use high power until the charge melts, then refine with low power for 5 minutes.

[0037] (2) Put the smelted FeSiAl master alloy into the crucible, wherein the diameter of the crucible nozzle is 0.5mm, the injection pressure is 3500Pa, and the vacuum is 5*10 -3 Pa, alloy ingots are remelted by induction coils under the protection of high-purity argon, and then quickly sprayed onto high-speed rotating rollers to obtain rapidly solidified flakes, with a rapid quenching rate of 26m / s. At the same time, the flakes are pre-broken to less than 1mm.

[0038] (3) The pre-crushed alloy powder is subjected to high-temperature ball milling for 10 hours. The temperature in the chamber of the ball mill is 300°C, the ball-...

Embodiment 3

[0041] (1) Put the following raw materials Fe 92%, Si5%, and Al 3% into an intermediate frequency vacuum induction furnace with alumina as a crucible for smelting, and vacuumize to 10 -3 Pa, filled with high-purity argon until the pressure in the furnace is 5*10 4 Pa, use high power until the charge melts, then refine with low power for 5 minutes.

[0042] (2) Atomize the above alloy melt into alloy powder through an ultra-high pressure water atomization powder making device.

[0043] (3) The pre-crushed alloy powder is subjected to high-temperature ball milling for 10 hours. The temperature inside the ball mill cavity is 400°C, the ball-to-material ratio is 5:1, and the rotation speed is 400r / min;

[0044] (4) Add a binder to the alloy powder after ball milling, the amount of the binder is 0.9% of the weight of the FeSiAl alloy powder, press the above material into shape, the mixing pressure is 30kN, annealing treatment at 150°C for 10min, and the target product is obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com